Endurance bench for cartridges for taps

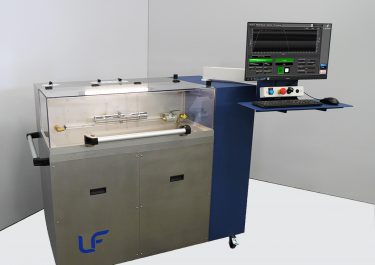

Hydraulic test bench to test 6 mechanical mixing valve cartridges simultaneously and independently.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Design and construction of a hydraulic test bench to meet current standards with accurate monitoring of pressure, temperature, flow, force and torque measurements. Our client wishes to test its samples in order to estimate their life expectancy, performance and hydraulic characteristics.

Creation of a test set to perform endurance tests on 6 different products or samples. Need for simplicity and speed of testing.

Problematic Issues

Our customer needs to test the endurance of thermostatic cartridges of mechanical mixing valves. He wants to test several products simultaneously and independently. His request was for 6 test stations.

Solution and Result

Our engineers have created a hydraulic test system consisting of 6 test stations. These test machines operate independently and simultaneously. They measure pressure, temperature, flow rate, force and torque while evaluating the conformity of thermostatic cartridges of mechanical mixing valves to current standards.

The endurance test bench has a safety system that automatically stops the test in the event of a fault and protects the operators in the event of a leak in the product under test.

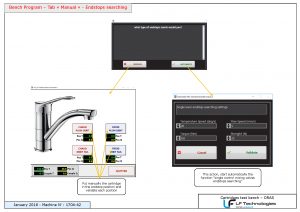

Our experts have developed software specific to this test machine. Easy to use, it automatically produces and edits test reports. The test bench can be controlled remotely and the transfer of information and documents is made easier.

Creation of a cartridge endurance test bench with a high degree of flexibility in the processing and analysis of sanitary components, meeting the standards governing the European markets.

Endurance bench incorporating a modular system that can test different types of mechanical cartridges independently of each other.

- Presence of a booster on each station, in order to test the tightness at 16 bar

- Measurement of accuracy, sensitivity, flow determination, etc.

- Leakage measurement / Leakage calculation

- Setting of temperatures, cartridge flow rates with torque or force measurement

- Monitoring of temperature and supply pressure

- Automatic report generation

Products tested

Mechanical mixing valve cartridge

A mechanical mixing valve cartridge is the element inside the mixing valve that regulates the mixture of hot and cold water (and therefore the temperature) and the flow rate.

Mixing tap

A mechanical mixing valve cartridge is the element inside the mixing valve that regulates the mixture of hot and cold water (and therefore the temperature) and the flow rate.

Cartridge endurance bench Cartridge endurance bench

This test bench carries out endurance and performance tests on mechanical mixing valve cartridges.

Cartridge test bench for mechanical mixing valves with independent stations

The test bench is equipped with 6 test modules operating independently and simultaneously.

Mechanical mixer cartridge test bench

Mechanical mixer cartridge test bench

Mechanical mixer cartridge

Mechanical mixer cartridge

Extract from the cartridge bank software manual

Extract from the cartridge bank software manual

OUR KEY TEST BENCH FOR THESE TESTS Endurance bench for LifeCartM mechanical cartridges

The tests are carried out to meet standards such as EN 817 and NF 077.

- Measurement of accuracy, sensitivity, flow determination, etc.

- Leak testing and static pressure testing at 16 or 25 bar

- Temperature control with torque measurement

- Flow control with force measurement

- Measurement and monitoring of supply temperature and pressure

- Endurance cycles

- Automatic report generation

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.