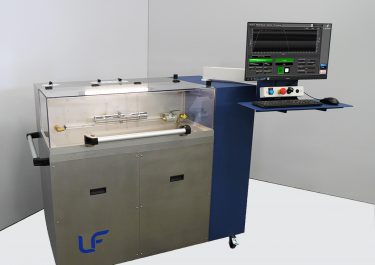

Hydraulic performance bench for mixing valve

Hydraulic test bench for performance measurement, tests many products and has many applications.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

We supply test benches manufacturers or distributors of taps, mechanical cartridges or thermostatic cartridges.

Main functions

Objective

To design a test bench that can automatically test all types of taps and cartridges for compliance with standards.

The bench must be able to accommodate a variety of product geometries and adapt to our customers’ hot and cold water supply systems.

PROBLEMATIC ISSUES

Our customers each had specific testing issues in their field:

For faucet manufacturers :

- Performing R&D testing, and verifying compliance with standards.

For cartridge manufacturers:

- R&D testing and verifying that their customer’s product (faucets), which will incorporate the cartridge, will comply with the standards.

For faucet distributors:

- Verify the product characteristics announced by the suppliers. Test products returned by customers to assess defects.

For testing laboratories:

- Verify compliance with standards.

In addition, each customer has different hot and cold water supply systems, so our bench must be able to adapt to these different architectures.

SOLUTION AND RESULT

Design of a performance bench capable of testing several types of product (cartridges, mechanical or thermostatic valves, etc.).

LF Technologies has designed a modular performance bench that can be adapted to a wide range of products, whatever their geometry, and integrated into customers’ various hot and cold water supply systems.

In particular, this bench incorporates an adjustable valve positioning and orientation system, and an arch allowing motorised actuators to be fixed in a multitude of directions, to adapt to different product geometries.

The design of this bench is modular, incorporating many different options (modules). Thanks to this modular design, we can offer optimised equipment for different types of valve and tested standards.

These different modules can also be adapted to a wide range of hot and cold water circuits (closed or waste water circuits, pressurised or gravity feed, temperature control within the bench, etc.).

The control software enables tests to be carried out in manual or automated mode according to programmable test procedures. The bench is supplied with test procedures that comply with standards.

Tested product

MECHANICAL MIXING VALVE

Single taps, mixers, mechanical mixers, thermostatic mixers, timed taps, electronically controlled taps, sequential mixers, mechanical cartridges, thermostatic cartridges and other tap products

BRASS THERMOSTATIC CARTRIDGE

Thermostatic cartridges are valve components. They automatically regulate the water temperature.

Mixing faucet

Mixing faucet

Thermostatic cartridge

Thermostatic cartridge

Performance bench for thermostatic mixing valve

The Perf-Multi performance test bench is designed to test the mechanical strength and hydraulic cartridges of taps, mixers and thermostatic and mechanical mixing valves;

Stand-alone performance bench

The Skydrobench is a complete set of test benches capable of carrying out performance, endurance and adjustment tests on all types of sanitary valves.

Performance bench for mechanical mixing valves;

The Perf-Valve performance test bench is designed to test the mechanical strength and hydraulic cartridges of faucets, mixers and thermostatic and mechanical mixing valves.

Mechanical Mixer Test

Endurance test of a mechanical mixing valve to NF077 standard. The mixer’s movement is achieved by a computer-controlled synchronized rotary actuator and linear actuator.

OUR KEY TEST MODULE FOR THESE PERFORMANCE TESTS for mixer taps PERF-VALVE

The performance test bench for faucets and mechanical mixers is a test bench designed to measure the performance of valves equipment by means of measuring instruments. The station can test the mechanical resistance and hydraulic characteristics of mechanical faucets and mixers.

This test bench can be used by :

- R&D for design ;

- prodcution for routine tests ;

- laboratories for characterization, qualification and verification of compliance with standards .

Our valve test benches are designed on a modular basis and can be equipped with a software allowing to automate testing to control measuring instruments, perform standardized tests independently, and provide a documented report. The software is in charge of conducting test scenarios (flow, temperature control, test sequences according to standards, etc.), tracking measurement results, performing calculations and editing a result report.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.