French manufacturer of embedded systems and submersible equipment for extreme environments

LF Technologies designs waterproof on-board systems and submersible equipment for marine and offshore environments, which are subject to numerous constraints. Our solutions are designed for autonomous underwater vehicles (AUV, UUV), ROVs, inspection drones and offshore infrastructures.

Our expertise enables us to meet the needs ofoffshore manufacturers, subsea maintenance operators and defence contractors, by offering equipment with integrated electrical controls capable of withstanding pressure and corrosion, while ensuring reliability, precision and long operating life.

You have a porject ?

I will be happy to advise you and propose solutions tailored to your needs.

Thibault MARCHAND

Subsea Equipment Division

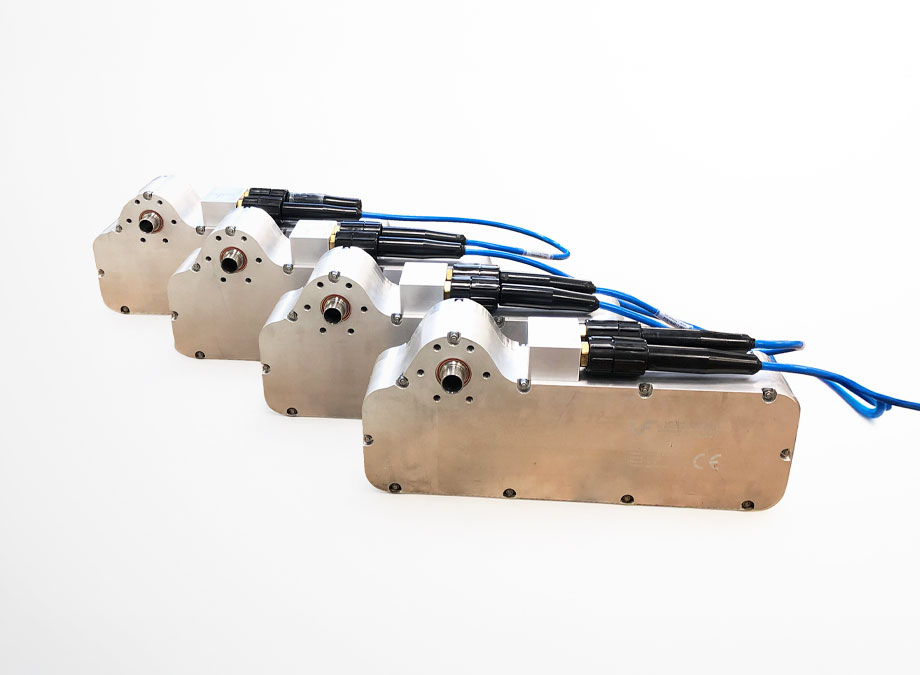

On-board modules designed for great depths

Our onboard systems enable you to control submerged devices and collect and process data underwater, while ensuring reliable communication with your command and control system. Designed to withstand high pressures, our modules have a modular architecture that makes them easy to integrate on all types of platforms or underwater craft.

Main features:

- Waterproof on-board electronics for protection in deep water

- Communication protocols: CAN, RS232, RS485, Ethernet, Modbus TCP

- Power supply: 24 to 72Vdc, optimised for submersible infrastructures

- MacArtney-type watertight connections for fast, secure integration

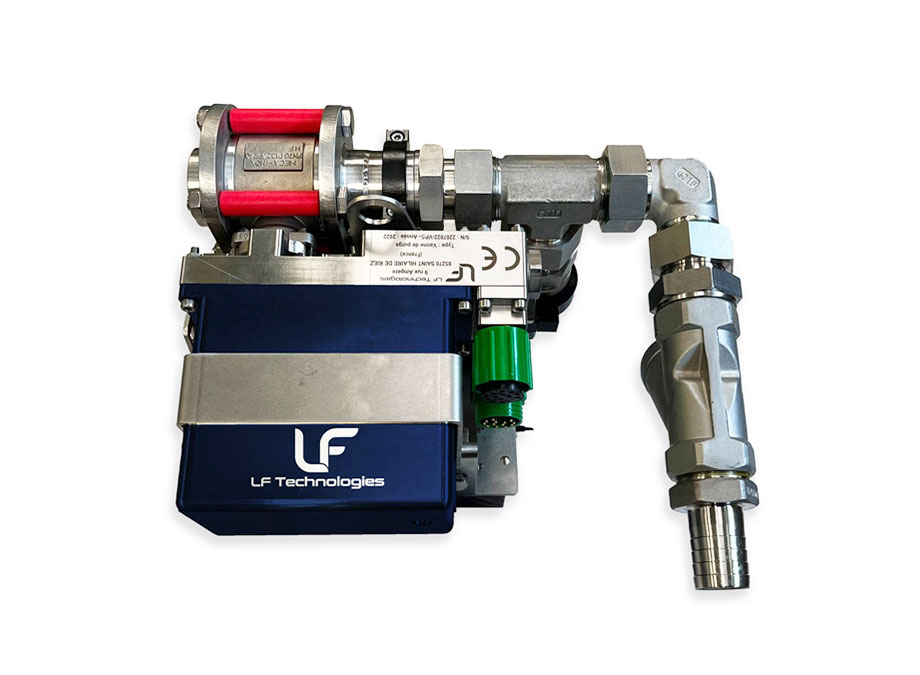

Submersible actuators – Power and precision under water

Our linear and rotary actuators provide precise, reliable mechanical control underwater, even in the most demanding environments.

Main applications :

- Rudder actuators for ROVs and underwater drones

- Underwater valve control for controlled flow regulation

- Automation of submerged structures for offshore operations

- Actuation of arms and on-board mechanisms on ROVs and underwater drones

Designed to operate at great depths, our actuators combine robustness, stability and long-lasting precision with low maintenance requirements.

Seamless integration into subsea infrastructures

Thanks to our expertise in watertight drive systems, subsea electromechanical solutions and communications systems, we design reliable equipment for critical operations in subsea environments.

Submersible engineering expertise for your subsea applications

At LF Technologies, we support you at every stage of your subsea project, with complete mastery of technologies such as watertight motorisation, onboard electronics, precision actuators, control interfaces and communication protocols adapted to your protocols.

Our equipment is designed to withstand the extreme conditions encountered in deep immersion, and each piece of equipment is pressure-tested in our workshops. This rigour enables us to work on a wide range of projects in sectors where reliability is essential:

- Offshore inspection and maintenance: work on submerged infrastructures, pipeline inspection, integrity checks.

- Underwater environmental monitoring: data collection under prolonged immersion, analysis of marine ecosystems.

- Special operations and maritime defence: equipment dedicated to military applications, strategic surveillance and specific interventions.

Each project in a submersible environment imposes unique constraints: high pressure, corrosion, limited access, reduced maintenance.

Our technical teams offer tailor-made solutions, from initial technical advice through to thecomplete integration of your onboard waterproof systems, whether for an underwater drone, an offshore infrastructure or an autonomous surveillance system.

What is a subsea watertight system?

A subsea waterproof system is a system capable of operating at depths of several hundred metres in seawater. These systems are generally fitted to vehicles or subsea installations. In addition to waterproofing issues, these systems need to be optimised to ensure that they are compact, have limited mass, are energy-efficient to improve vehicle autonomy and operate as autonomously as possible to limit the number of connections between each element of the installation.

Thanks to its experience in submersible engineering, LF Technologies designs robust solutions capable of withstanding the pressure of deep immersion. Each system is designed to integrate easily with subsea platforms and guarantee the reliability required for critical operations.

Why use a subsea watertight system for an ROV?

A subsea watertight system allows ROVs to operate reliably at great depths, by being positioned directly in the submerged part, without the need to be integrated into the watertight hull.

Building on its expertise, LF Technologies develops compact and robust solutions, specially adapted to the constraints of autonomous or remotely operated underwater vehicles. Our systems are designed to guarantee the performance and durability of the equipment fitted to ROVs.

Why use electrically operated systems?

Subsea actuators are generally operated either hydraulically or electrically. Electrically operated actuators offer a number of advantages, including operation without a hydraulic power plant, no hydraulic connection hoses and more autonomous operation thanks to on-board control electronics. What’s more, these systems can communicate with the control system to receive control commands and report their operating status (which is essential for monitoring and maintaining subsea systems, which are generally not easily accessible).

LF Technologies offers a range of electrically controlled subsea actuators and systems, with integrated control systems and a multitude of protocol, power supply and connector choices. We can also offer customised systems designed directly to your application.

Which communication protocols are supported?

LF Technologies offers modular solutions that integrate easily into existing infrastructures, with robust communication interfaces tailored to your control protocols.

What is the maximum depth supported by a watertight onboard system?

What materials are used in a sealed on-board system?

At LF Technologies, we rigorously select materials according to the constraints of use, in particular favouring titanium, marine stainless steel and high-performance polymers to guarantee reliability and durability in extreme conditions. We can adapt our choice of materials to those already used on your other underwater equipment.