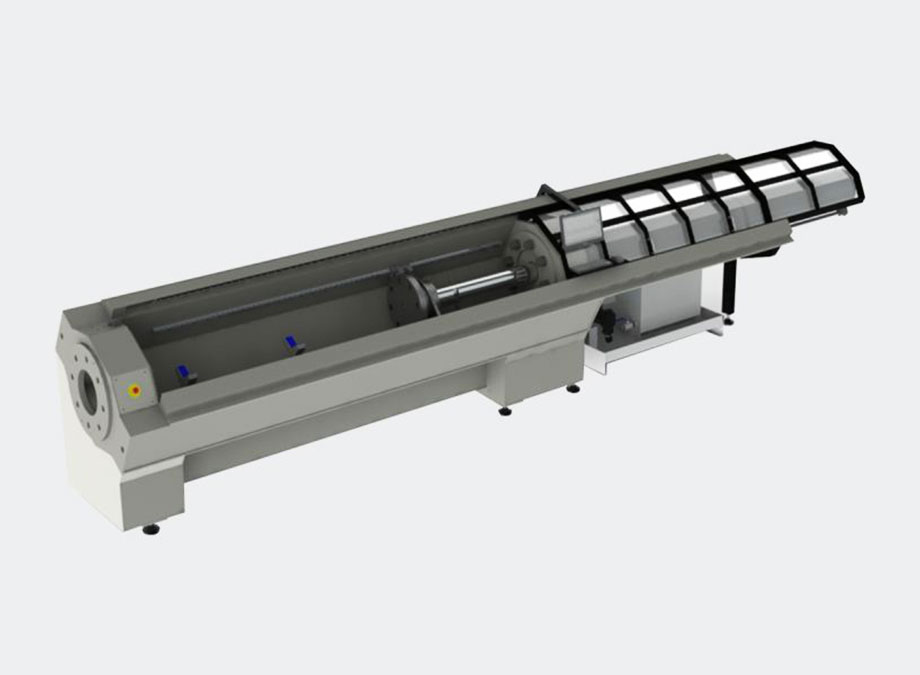

Tensile and Compression test Benches

In the field of research and innovation, assessing mechanical strength to guarantee product quality and durability is essential. This is where tensile and/or compression test rigs come into play, proving to be important pieces of equipment. Designed to assess the strength of your materials or finished products in the face of compressive and tensile forces, these test benches are tailored to your specific requirements, whether in terms of ‘product’ or ‘test process’ constraints. This flexibility ensures precise and adaptable control, essential for effectively testing a wide range of products.

Customer applications

Discover LF Technologies’ expertise in tensile test benches and compression test benches through our customer applications.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

What is the role of a tension and compression test bench in industry ?

A tension/compression test rig is a piece of mechanical test equipment used to characterise the behaviour of a material or component subjected to tensile or compressive stress. At LF Technologies, we develop customised test benches capable of reproducing real-life conditions, to guarantee the reliability, quality and safety of your products.

These mechanical tests are essential for measuring the breaking strength, deformation or durability of an element, whether it is a raw material, a semi-finished product or an assembled component.

Why opt for a made-to-measure traction/compression bench?

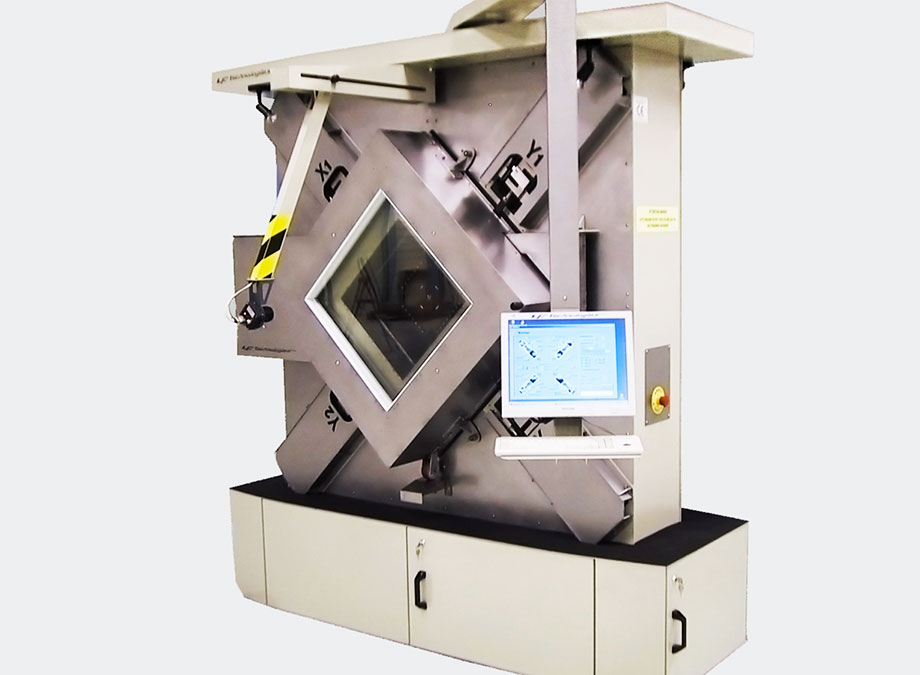

Standard testing machines are designed for standardised specimens. They are not always suitable for testing finished products or complex geometries. LF Technologies designs customised test benches tailored to the specific requirements of each industrial application.

Our equipment can be used to simulate realistic stresses on your parts: uniaxial tension, axial compression, bending, long-term creep tests or low-frequency fatigue tests. Each solution is developed to fit in with your test environment and meet your validation objectives.

Thanks to our expertise in test bench engineering, we design fully customised equipment, incorporating your mechanical, geometric and standards requirements.

What type of test rig should you use for your tensile or compression tests?

LF Technologies integrates a variety of technologies to meet all industrial needs in terms of mechanical testing:

- Drive technology: hydraulic cylinders for high loads, electric servo motors for high precision and low inertia.

- Guide technology: single columns for improved ergonomics or multi-column structures for greater rigidity. Compression guides to limit parasitic forces.

- Control technology: force, displacement or mixed control; quasi-static tensile tests, prolonged creep, fatigue or mechanical shock tests.

To study the behaviour of materials under prolonged loading, we design creep test benches dedicated to slow deformation testing under constant stress. These tests are essential for anticipating the ageing of materials under real-world conditions.

We also offer hybrid test benches, capable of combining several types of stress and test regimes, for complex or multi-physics applications.

What mechanical tests can be carried out on a customised test bench?

Our tensile and compression test benches are used in a wide range of industrial environments:

- Aeronautics: compression tests on primary or secondary structures, impact or inertial load simulations.

- Automotive: tensile tests on plastic parts, fatigue tests on structural components.

- Research : compact benches that can be integrated into test chambers or controlled environments.

- Textiles & soft materials: multi-axis tests to study the elasticity and mechanical strength of technical fabrics.

- Sports equipment: combined benches for testing the performance and lifespan of components subjected to repeated cycles.

In addition to conventional tensile and compression tests, we also carry out torsion tests to assess the rotational strength or angular rigidity of technical components.

How can you validate the mechanical strength of your products using tensile and compression tests?

By integrating a mechanical test bench into your validation processes, you have access to reliable data for :

- Check that your products comply with current standards;

- Testing load-bearing capacity under extreme conditions;

- Optimise design from the earliest stages of development;

- Detect weak points through destructive or non-destructive testing;

- Improve safety of use and anticipate mechanical risks.

At LF Technologies, each tension/compression test bench is designed to meet our customers’ business requirements with precision, with a focus on performance, innovation and industrial reliability.

Expert advice

Explore our blog dedicated to the world of mechanical test benches.

Immerse yourself in engineering excellence and discover the latest advances, tips and trends in the field.