Hydraulic test bench for valve endurance | LF Technologies

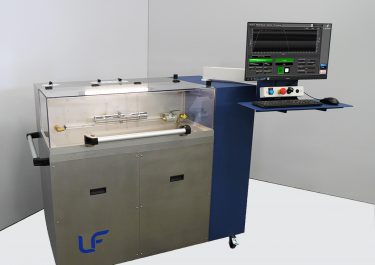

Modular hydraulic test stand dedicated to endurance testing.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client, a French company, is a European leader in the market for taps and sanitary equipment for public buildings (ERP).

Main functions

Objective

The customer requires a valve test rig to test the endurance of their entire range of electronic valves, timed valves and thermostatic mixing valves. These types of hydraulic test rigs are designed to test the life and reliability of the valves in their future life cycle by accelerating ageing and therefore wear and tear of the product.

PROBLEMATIC ISSUES

The challenge here is to find a way to perform several hydraulic endurance tests at the same time in order to reduce costs and overall test duration.

Indeed, this type of fatigue test requires long cycles. We are talking about several million cycles in a stand-alone manner, so it is important to optimise the test times.

We must therefore develop a hydraulic test bench capable of being modular and versatile. We also need to work on the size of the bench in order to optimise the space dedicated to the machines at the customer’s premises.

Solution and result

Our engineers have designed a set of modular hydraulic test benches dedicated to endurance. Its scalable aspect allows the customer to test different equipment according to his needs, thanks to actuators and tools adapted to the valves.

Each test bench is equipped with sensors to measure pressure, flow rate and temperature of the supply, temperature and flow rate of the output, volumes of cut-off, positions, force and torque of operation.

We worked on the integration of the components inside the bench to optimise the size of the structure. This allowed us to minimise the footprint of the test benches. This means that they can be placed next to each other without taking up too much space in the customer’s laboratory. The rear of the test stand is completely free to allow access to the machine’s hydraulic system.

The control software comes with a set of pre-programmed and parameterised test procedures. It allows endurance tests to be carried out that correspond to the standards applicable to sanitary valves (ISO, DIN, ASTM, BS, EN, JIS). It is also possible to program tests that correspond to the expectations of various certifications such as the NF mark issued by the CSTB and AFNOR.

Following the execution of the hydraulic test, it is possible to obtain a test report containing the test results, the parameters of the test procedure, the product information, the date and the user comments.

In order to maintain the equipment, we have offered the customer a maintenance contract for the test benches with scheduled audit, calibration and revision visits.

Are you also looking to test your valves, but are you lost in the standards and certifications ? It couldn’t be easier: contact us and together we’ll work out a solution that’s right for you. You can also consult our range of hydraulic test benches for more information on performance, endurance or control benches.

TESTED PRODUCT

ELECTRONIC MIXING VALVES

It is a hydraulic test bench developed to test all types of sanitary faucets (simple faucet, timed faucet, mixing faucet, electronic faucet, mixer, etc.).

OUR KEY TEST BENCH FOR THESE TESTS Endurance test bench for fittings LIFEMULTI

Main functions

The endurance test bench is a test bench for testing the service life of valves, mixers, reversing valves, mechanical and thermostatic mixing valves in a fully automated way and according to NF, EN, ASSE etc.

The machine is equipped with an automated measurement system that assesses the reliability of the valve during its life, based on changes in operating torque and tightness.

Operating mode

Find out how our endurance test bench for valves works

- Attachment of the valve to be tested to the central plate;

- Setting the position of the valve;

- Mounting the actuators for movement control (rotation or translation);

- Programming the tests on the control screen;

- Starting the scenarios.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.