Static and cyclic pressure bench

Cyclic pressure test bench for static and alternating pressure leakage testing of fittings and shower accessories.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client designs and manufactures sanitary fittings and accessories.

Main functions

Objective

Carry out static pressure and alternating pressure leakage tests on taps and shower accessories.

The bench must be capable of carrying out the following tests:

- static pressure 16, 25, 35 and 100 bar.

- alternating pressure from 8 to 50 bar with a frequency of 1 Hertz.

PROBLEMATIC ISSUES

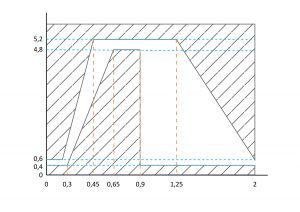

Standard NF077 – Doctech 3 includes water hammer tests with strict characteristics (see graph):

- Very rapid pressure build-up (from 5 to 50 bar in 0.15 s)

- High pressure control accuracy (2%)

Various systems exist, in particular the pneumatic pressure intensifier, which allows pressure to be increased rapidly but with very little precision.

SOLUTION AND RESULT

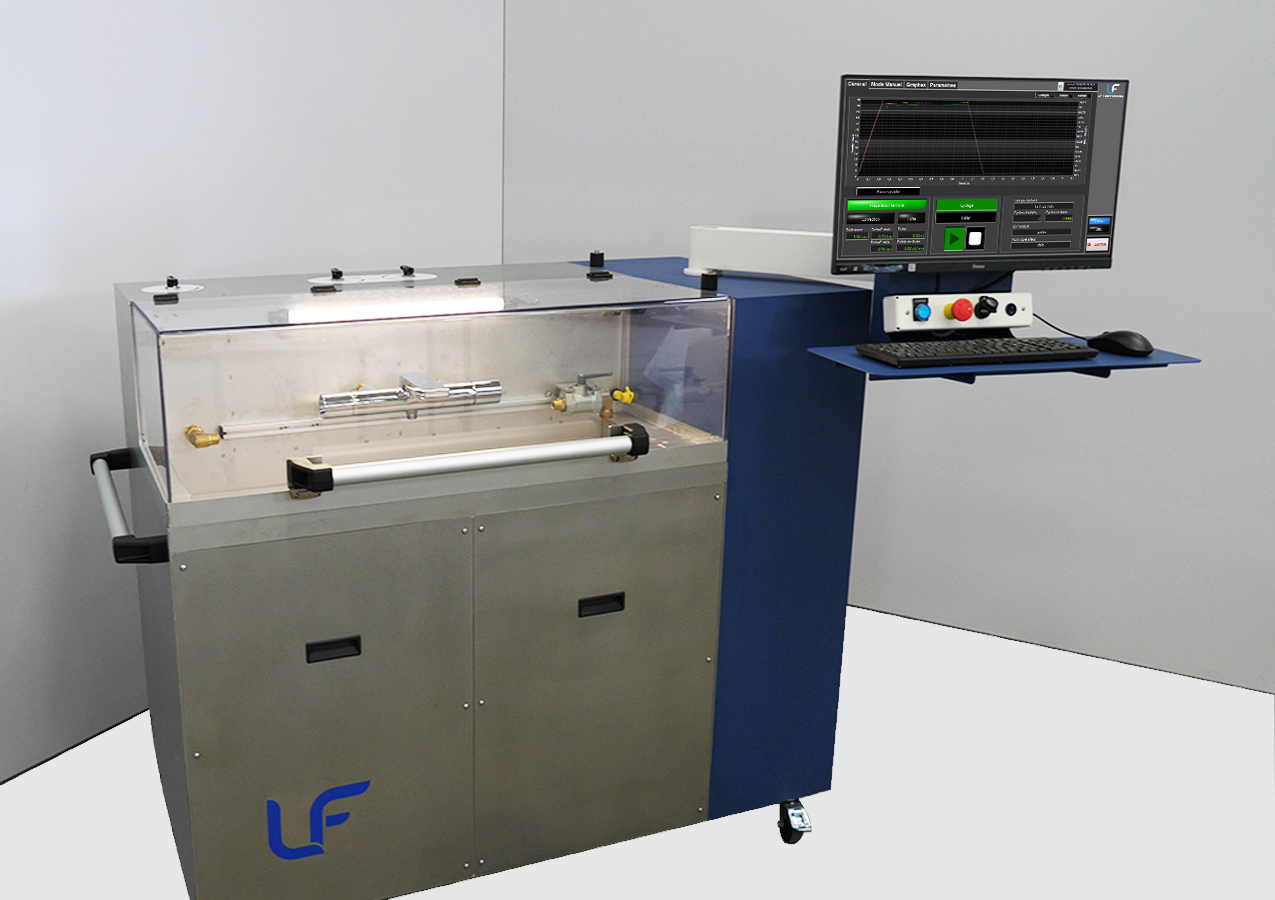

The proposed equipment is a self-supporting bench comprising a recovery sink, a bonnet, a hydraulic circuit, a cyclic and static pressure generator and a control unit.

The bench is connected to the water supply circuit. The pressure in the connection circuit allows air to be bled from the circuit.

The bench is equipped with a pressurisation system using a motorised plunger piston to compress the water in the circuit. The displacement of the pressure generator piston gives a volume measurement. A sudden change in this volume measurement allows the detection of a leak or burst.

To ensure accuracy and speed, the plunger is in this case directly controlled by the drive, so the control loop is much shorter. The control system is based on self-learning cycles and pressure-dependent piston travel. The control software applies corrections to ensure the correct pressure and speed of pressure build-up.

The product under test is connected to the tapping points on the front panel. Manual valves allow the product to be fed or vented.

A bonnet system fitted with a safety switch cuts off pressurisation if the bonnet is not closed. This ensures operator safety.

Tested product

Robinet thermostat

Feed manifold

OUR KEY TEST BENCH FOR THESE TESTS Valve test bench – static and cyclic pressure HydroShock

Main functions

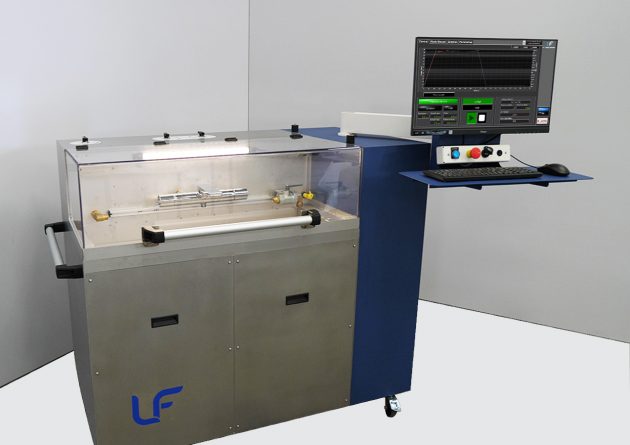

This tap test bench is designed to test the tightness and pressure resistance of taps and tap accessories (flexible hoses).

The bench can perform static pressure tests, up to bursting and alternating pressure tests to simulate water hammer.

Operating mode

The product under test is connected to the tapping points on the front panel. Manual valves allow the product to be fed or vented.

The bench is equipped with a pressure system using a motorised plunger piston which compresses the water in the circuit. The displacement of the pressure generator piston gives a volume measurement. A sudden change in this volume measurement allows the detection of a leak or a burst.

The system is equipped with a self-learning system that ensures automatic adjustment of the pressure cycle parameters, which optimises the pressure cycle shape without any user intervention.

The test area is equipped with a transparent cover with a safety switch that cuts off (or prevents) the pressurisation if the cover is not closed.

Bench developed to meet these standards:

NF077 – Doctech 3

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.