Our proven solutions

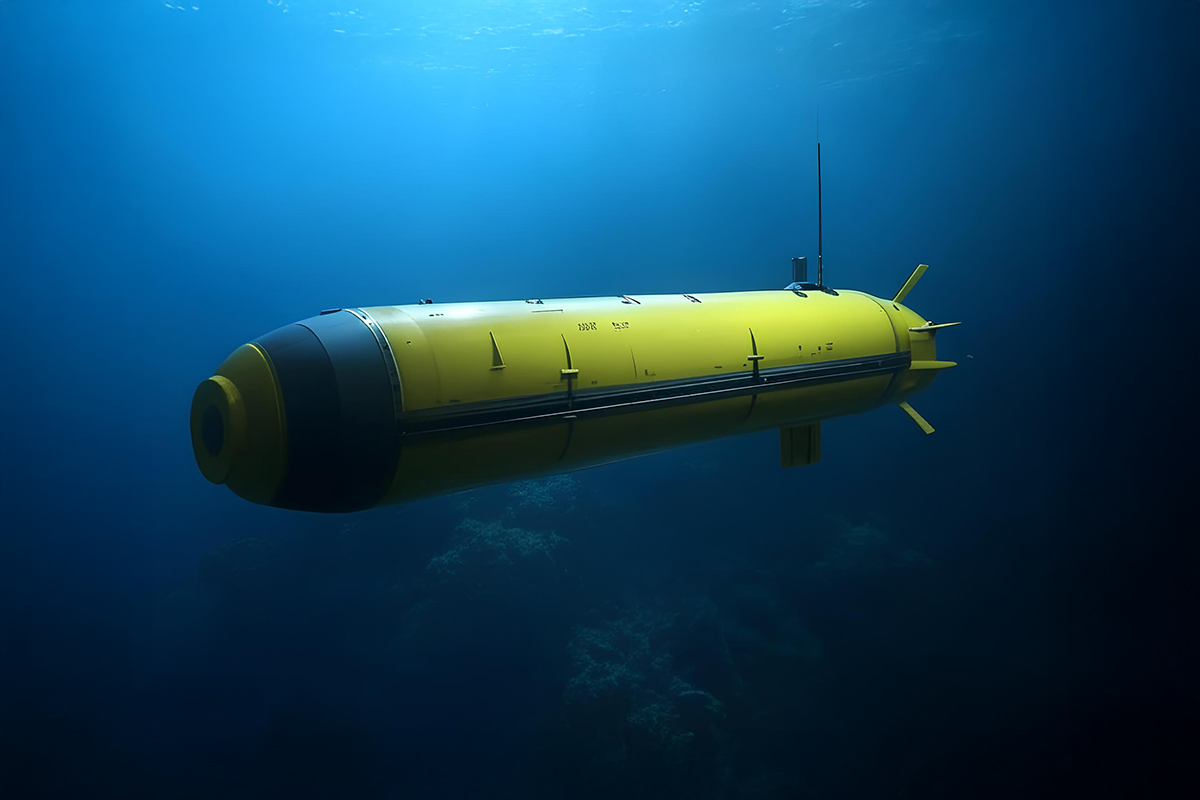

Discover our special machines that have become standards

We meet your challenges

- Optimization of manufacturing, assembly and inspection processes

- Efficiency of a dedicated solution

- Traceability of operations

- Workstation ergonomics

- Ease of use

Your turnkey project

Discover the different stages of our support, from drawing up specifications to commissioning.

LF Technologies, Designer and Manufacturer of Special Machines

LF Technologies specializes in the production of special machines that are 100% Vendée-made and perfectly adapted to your needs. Our design office works closely with you to customize each machine, ensuring optimum compatibility with your products and processes. Whether the goal is to automate or improve a manufacturing process, our team of engineers is ready to bring their expertise to your projects.

Modular solutions for maximum adaptability.

Our special machines are characterized by their high degree of modularity, offering solutions tailored and optimized to your requirements. Our functional modules, which are essential to the realization of our customized production lines, can also be integrated into your existing automation systems. This flexibility, combined with our know-how, guarantees a result that meets your requirements, whether in terms of equipment quality and durability, or expected performance.

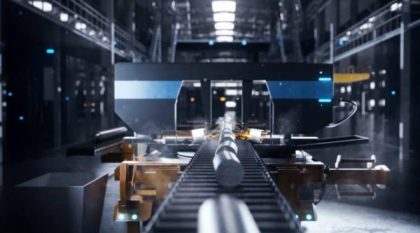

Advanced robotics for increased productivity.

Robotic arms, such as Cartesian or SCARA robots, are integrated into our modules for precise and reliable handling of parts. This integration ensures safe and repetitive handling, reducing the physical strain of certain manual tasks. Our expertise in robotics is a significant asset to increase your productivity and achieve a quick return on investment.

Each module is designed to adapt to your activity’s rhythms, allowing for significant productivity gains. LF Technologies’ creation units easily integrate into your existing lines and are deployable across different production sites, thanks to our personalized approach and our international project team.

LF Technologies: Your Partner for High-Performance Production

By collaborating with LF Technologies, you benefit from special-purpose machine solutions that meet and adapt to your expectations. Our commitment to innovation and customer satisfaction positions us as the ideal partner to guide your company towards enhanced efficiency and productivity.

Put your trust in LF Technologies

Over 30 years ' experience

LF Technologies has been supplying products and solutions to meet the specific requirements of special-purpose machines, test benches, measuring and control equipment, and assembly machines with a high level of control and traceability since 1995.

Reliability & performance

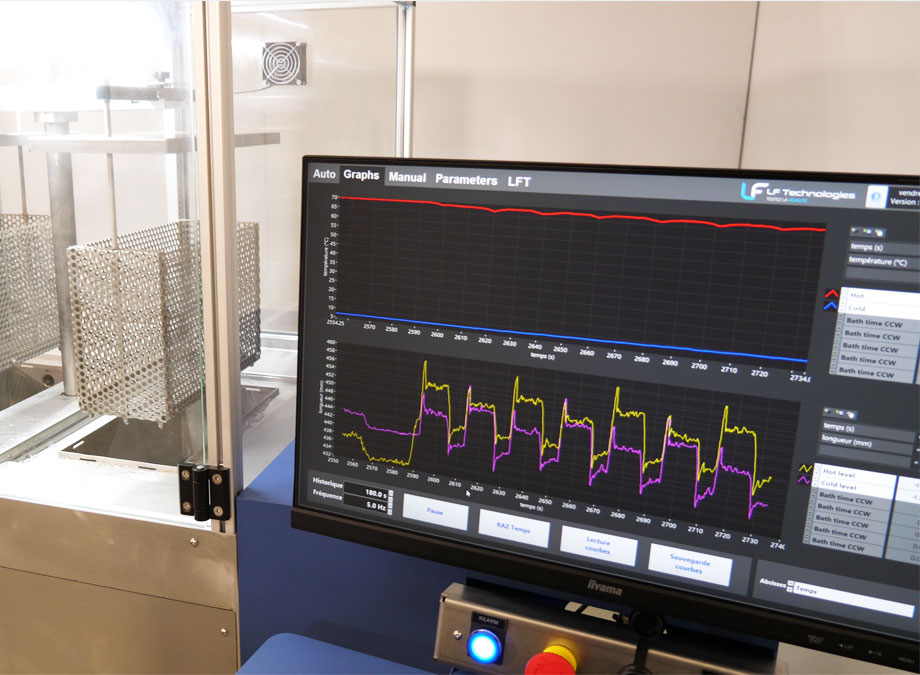

Reliability and precision are at the heart of the tests carried out by LF Technologies. We use advanced technologies and rigorous procedures to guarantee data quality. You can trust our expert team to design your test benches with peace of mind. When you choose LF Technologies, you're choosing a partner of first choice, enabling us to create equipment that meets your expectations.

Made-to-measure & Confidentiality

LF Technologies designs customized test benches for industry, emphasizing confidentiality and exclusivity to protect innovations and industrial secrets. This approach is designed to strengthen trust with our customers and partners.

Turnkey project

In addition to our warranty, we offer you a maintenance solution for your machines. We can intervene to change spare parts, calibrate sensors or answer your questions about using your test bench or production machine.

Customer applications

Discover LF Technologies know-how through our customer applications.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

LF Technologies is

They trust us

What is a Special Machine?

A special machine is a machine designed to meet a specific industrial need. Unlike standard machines, they are developed to specific specifications, depending on the constraints, the product to be processed and the process to be automated.

What is the purpose of a special machine?

It can be used to carry out a single task or a series of automated operations, such as assembly, quality control, welding, piloting, packaging or mechanical testing. The aim is to improve productivity, reliability and safety on the production line.

Diversity and adaptability of special purpose machines

Special machines are distinguished by their diversity, offering customized solutions for :

- Assembly: Automated assembly of components into finished products.

- Control: automated inspection to guarantee product quality.

- Realization: Productivity increase with equipment specifically designed.

Improve your industrial processes with special-purpose machines

Design Innovations

At the heart of modern industry, the quest for productivity gains relies on the use of innovative machines, designed to precisely meet the unique needs of each industrial or manufacturing process. LF Technologies, a specialist in the design and manufacture of such customized equipment, enables us to meet these challenges by optimizing these processes and thus reducing product manufacturing costs for a variety of sectors, including the automotive, watchmaking, medical and sports equipment industries.

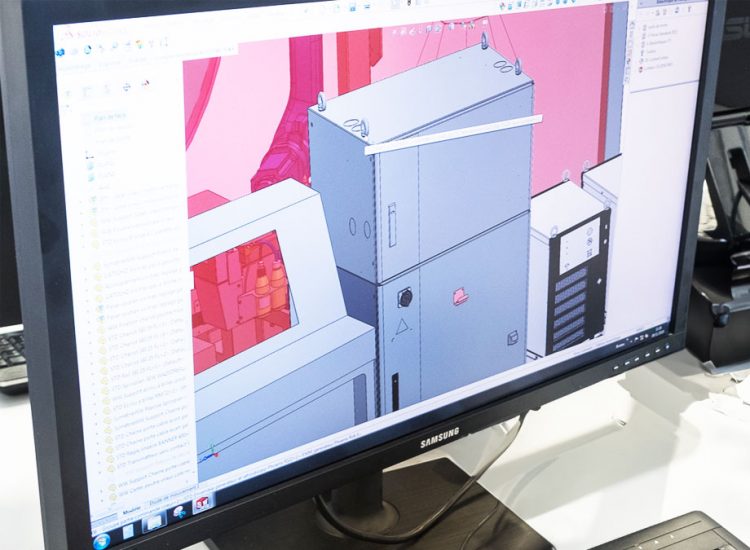

Our Design and Manufacturing Processes

The creation of a special-purpose machine at LF Technologies follows a rigorous process, ensuring solutions that are perfectly tailored to our clients’ needs:

- Needs Analysis: Evaluation of industrial processes to identify necessary improvements.

- Specifications: Drafting a document detailing technical and functional requirements.

- 3D Design and Modeling: Using advanced technologies to design and visualize the proposed solution.

- Manufacture and assembly: Precisely manufacturing components and assembling the machine.

- Testing and Validation: Checking compliance with requirements before delivery.

Industries Benefiting from Our Special-Purpose Machines

The solutions offered by LF Technologies find applications in numerous fields, bringing significant added value to:

- Automotive: For assembly and part inspection.

- Watchmaking: In assembly and quality processes.

- Medicine: For assembly, adjustment, and inline control.

- Building :To automate manufacturing processes of construction elements.

- …

LF Technologies: Your Partner for Industrial Innovation

Choosing LF Technologies means opting for recognized expertise in the development of customized robotic and automated solutions, 100% Made In France. Thanks to our team of experienced engineers, LF Technologies is committed to providing special machines that precisely meet our customers’ requirements, ensuring continuous improvement of their production processes.