Our experience at your service

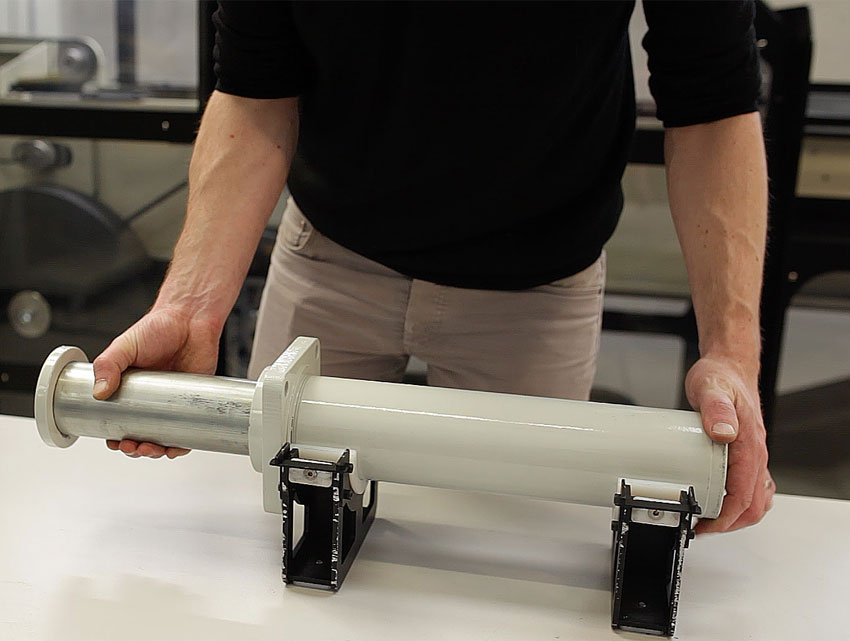

Design of customised test benches for your industrial requirements

Since 1995, LF Technologies has been designing and manufacturing customised test benches and industrial test benches in France, tailored to the specific requirements of each sector.

Specialising in hydraulic, mechanical and multi-domain test solutions, we can help you implement equipment that incorporates high levels of quality control, traceability and compliance with current technical standards.

Each test bench we design is precisely tailored to the requirements of the field. We pay particular attention to the constraints of your test environments, the standards in force, and the performance and quality objectives specific to your sector.

Whether it’s a controller dedicated to mechanical, hydraulic or electrical measurements, a simulation bench, submersible components for ROVs or AUVs or a special custom machine, each project is rigorously managed to guarantee reliable, scalable results that are integrated into your processes.

We design our test benches in France with the aim of supplying reliable, durable equipment that is perfectly suited to your needs.

the synergy of 3 skills centres

hydraulic test benches

Mechanical test benches

SPECIAL MACHINES

Your turnkey project

Discover the different stages of our support, from drawing up specifications to commissioning.

LF Technologies is

LF Technologies at your service

LF Technologies has expertise in revamping, industrial design andHMI, with the aim of offering you reliable, easy-to-use equipment.

RETROFIT

This service enables you to keep your machine up to date with the latest innovations, at lower cost, because we only change what's necessary.

INDUSTRIAL DESIGN

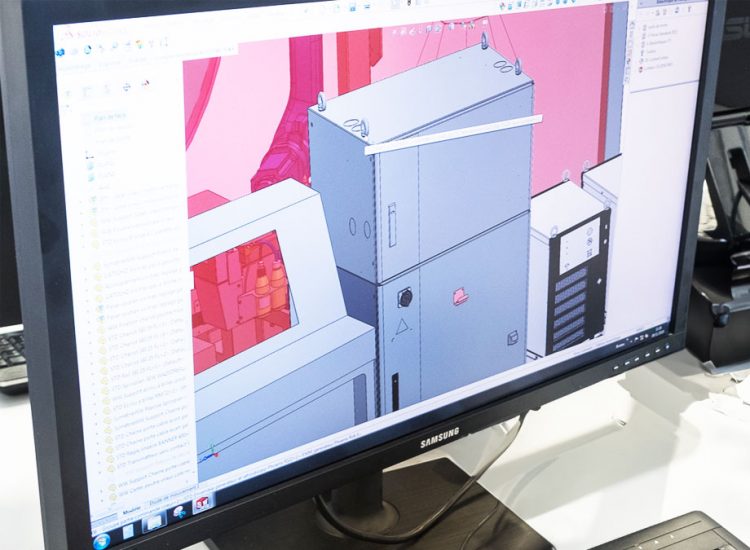

Mechanical design

LF Technologies, votre fabricant de banc de test & machine spéciale

Our team puts its know-how and experience at your service to design your test bench or special production machine.

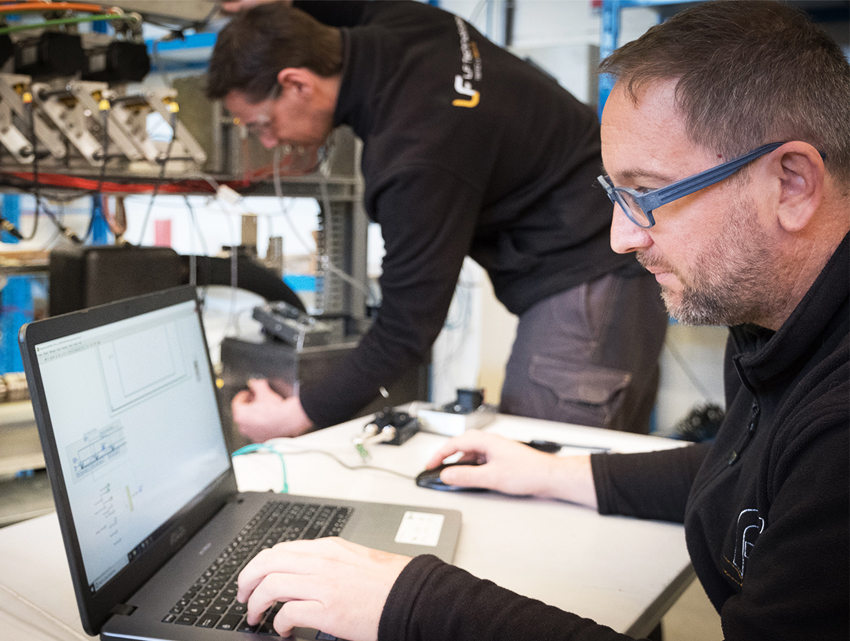

Expertise in mechanical design for industrial test benches

Our engineering department designs hydraulic and mechanical test benches and special production machines, taking into account your constraints, technical objectives and applicable standards. We place your products at the heart of our approach, so that we can offer solutions that are perfectly aligned with your specifications.

Thanks to the experience of our engineers and a fully integrated approach, we are able to adapt our standard benches or develop 100% customised equipment, designed to meet your exact requirements.

We are with you every step of the way: functional analysis, mechanical design, prototyping, manufacturing, right through to installation of the test bench in your workshops. It is this demand for precision and reliability that makes LF Technologies a trusted partner in the design of test benches in France.

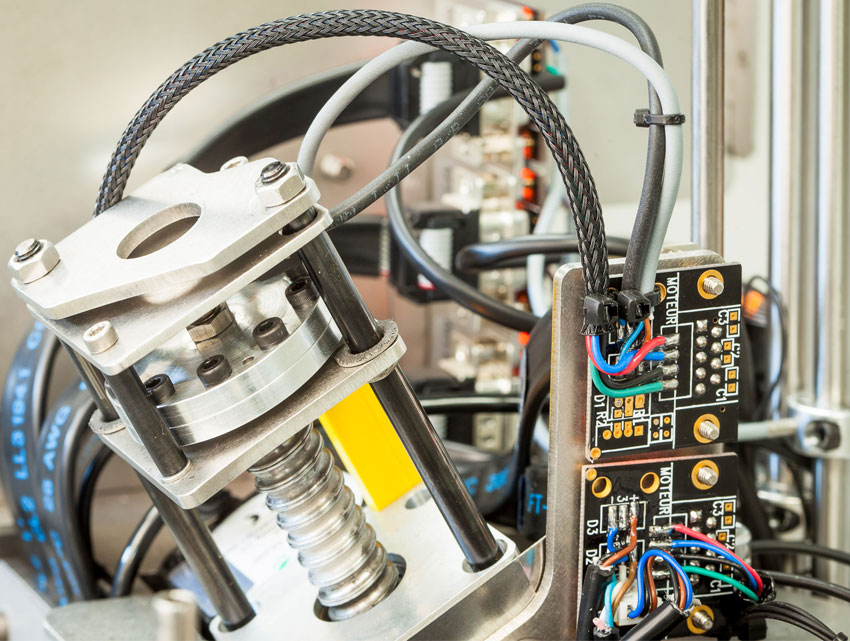

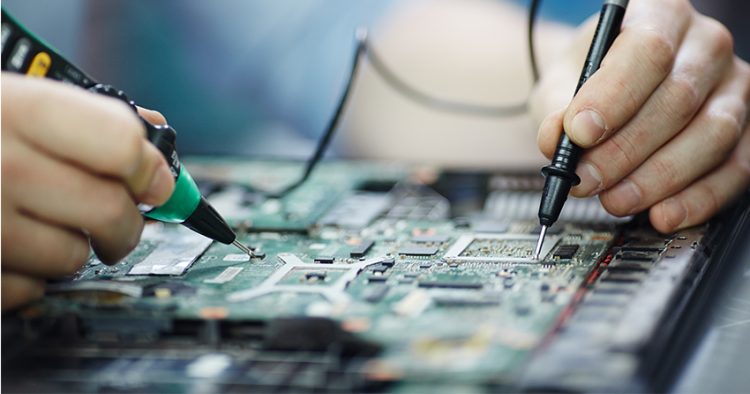

French electronics design for test benches

Our test benches incorporate electronic boards developed and manufactured directly in our workshops in Saint-Hilaire-de-Riez, Vendée.

This in-house expertise means we can guarantee the quality, reliability and scalability of the solutions we offer, while providing responsive technical support at every stage.

LF Technologies’ approach is fully in line with the French industrial dynamic, through the FIDEIP group and the French Fab movement, which promote innovation, know-how and national production in the industrial sector.

Measurement benches for reliable, standardised quality control

What is a measurement bench?

A measurement bench is a test bench designed to accurately check the conformity of products at the end of production, particularly in the hydraulic and sanitary sectors.

It is used to assess the actual performance of parts according to strict criteria, ensuring that they comply with the standards in force before they are put on the market.

LF Technologies designs these benches to guarantee rigorous traceability, reliable repeatability of results and direct integration into your production lines.

Designed and manufactured entirely in France, in our workshops in the Vendée region, our measurement benches provide robust, durable quality control tailored to your industrial requirements.

Test benches to guarantee the conformity of your products

What is the purpose of a test bench in an industrial environment?

An inspection bench is a test bench designed to validate the compliance of products with the expected technical specifications, before they are put on the market. It enables essential characteristics such as performance, resistance and safety to be reliably assessed.

At LF Technologies, we develop test benches adapted to hydraulic, sanitary and mechanical production environments.

This equipment plays a key role in your quality process and guarantees that each product complies with the applicable standards and your internal standards.

Designed and manufactured in France, our industrial test benches offer you precision, repeatability and robustness to safeguard every stage of your production.

Industrial test benches to test your products in real-life conditions

What is an industrial test bench and what is it used for?

An industrial test bench reproduces, in a controlled environment, the stresses to which a product will be exposed in real use. It is an essential tool for analysing the behaviour of components over time, checking their resistance to stress, or simulating complex cycles.

At LF Technologies, these benches are designed to meet specific needs: strength tests, functional validation, performance qualification in mechanical, hydraulic or electrical environments.

Their design takes account of the specific features of your activity, with attention paid to integration within your existing equipment.

Entirely developed in our workshops in the Vendée region, our test systems benefit from meticulous manufacturing, a scalable architecture and dedicated technical support, so they can be adapted to your test protocols over the long term.

Tailor-made test benches: a dedicated response for every project

Why design a customised test bench?

Each industrial environment has its own constraints. A tailor-made test bench provides a precise response to the specific requirements of a product, process or unique specification.

LF Technologies designs test benches for a wide range of applications: valves, hydraulic components, mechanical systems and electrotechnical equipment.

Our teams study your needs in depth to define a solution that takes account of available space, test conditions, existing tools and future developments.

Manufactured in our workshops in the Vendée region, this bespoke equipment combines robustness, ease of operation and adaptability.

They are designed to be a lasting part of your production and to support your projects over time.

Better understand the usefulness of a test bench

What is a test bench and what is it used for?

A test bench, sometimes called a test rig, is a piece of technical equipment designed to simulate real conditions of use. It is used to check the conformity, resistance or performance of a product.

At LF Technologies, we design test benches for a wide variety of components: sanitary fittings, industrial valves, gas equipment, mechanical parts or sports equipment.

These systems accurately reproduce stresses such as pressure, friction, flow or temperature.

How do I choose the right test bench for my industrial project?

The choice of test bench depends on several criteria:

- Parameters to be measured: pressure, temperature, torque, flow rate, etc. ;

- The types of products involved: valves, gas components, mechanical parts, technical textiles, etc;

- Standards to be complied with: ACS, ISO, NF, CE, or other industry standards ;

- The production environment: manual, semi-automated or integrated into a production line.

We support you from the feasibility study right through to the commissioning of the test equipment best suited to your needs.

Why use an automated test bench?

An automated test bench offers a number of advantages over a manual model:

- More reliable results thanks to reproducible test sequences;

- A significant reduction in cycle time;

- Fewer handling errors;

- Automated data collection for better traceability and easier analysis.

Automation is an integral part of the solutions we develop, with a view to performance and industrial continuity.

How does an industrial test bench work?

The principle is to recreate conditions of use in a workshop or laboratory to assess the behaviour of a component, product or assembly. A test bench generally consists of :

- a control system (PLC, interface, software) ;

- measurement sensors (pressure, temperature, flow, etc.);

- actuators or mechanical systems (pumps, actuators, solenoid valves, etc.);

- a monitoring module to collect and archive test results.

Each bench developed by LF Technologies is tailor-made to meet your technical objectives and can evolve according to the needs of your future test campaigns.