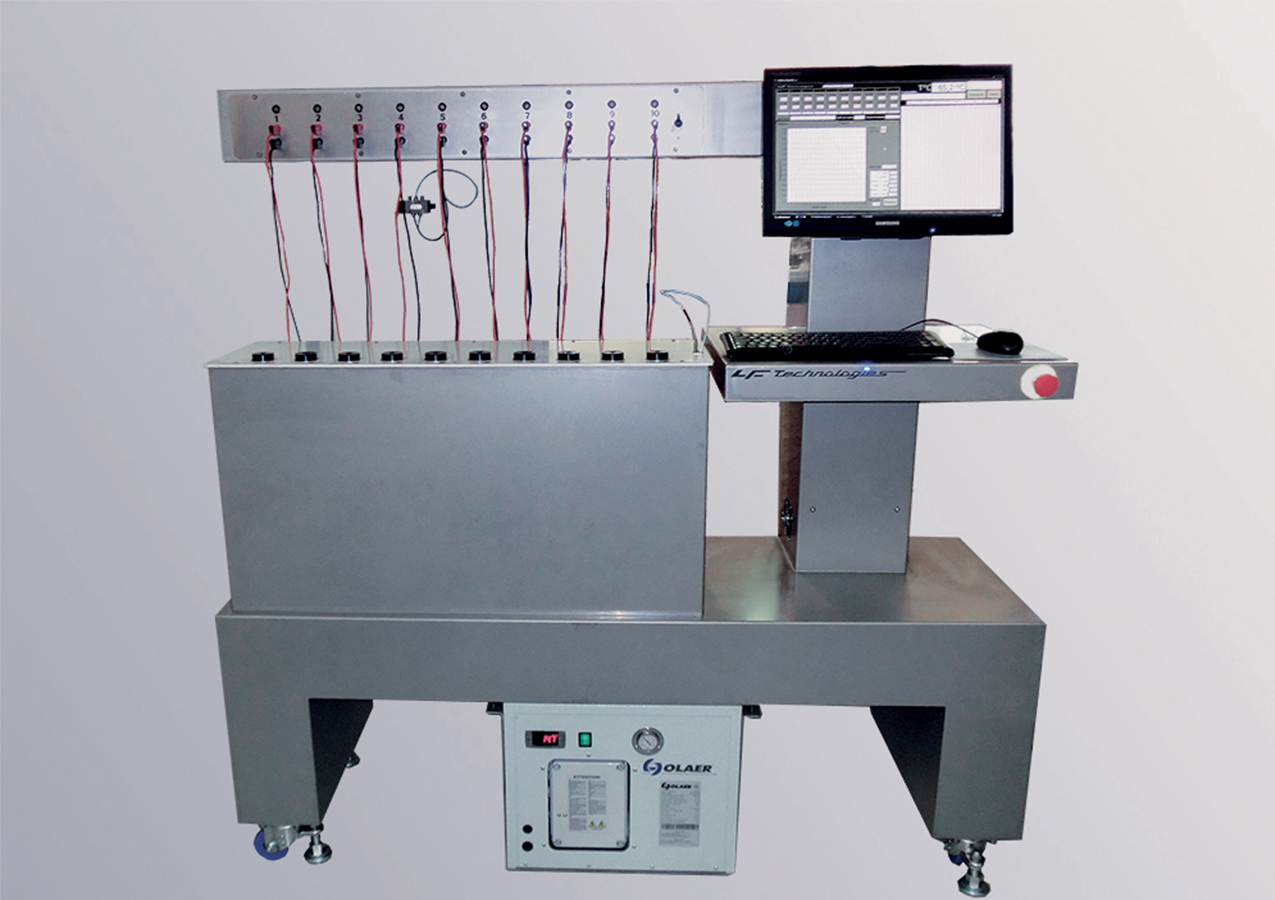

Thermostat control bench

Temperature cycling test rig for thermostats/temperature sensors. Automatic recording of test results. It carries out tests in accordance with standard NF EN 257.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is a French company specialising in the design and manufacture of thermal comfort solutions, and is the market leader in Europe.

Main functions

Objective

Check the temperature thresholds for rising and falling temperatures on several thermostats simultaneously.

PROBLEMATIC ISSUES

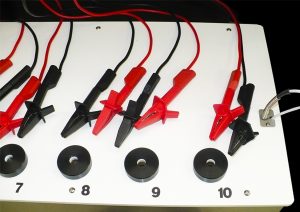

The control bench must be able to control up to 10 thermostats at the same time and the hydraulic circuit must be in closed loop. The system must be able to set optimised temperature rise and fall ramps that are gentle enough to obtain an accurate measurement of the changeover temperature and fast enough to allow rapid testing of the thermostats over a large number of cycles.

SOLUTION AND RESULT

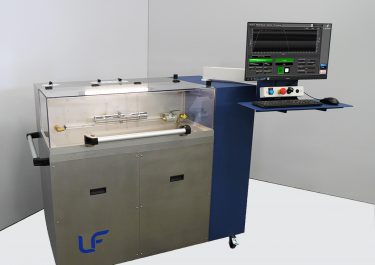

The teams at LF Technologies have designed a cyclic temperature test loop capable of controlling the heating or cooling ramps of 10 mechanical thermostats simultaneously. The bench carries out tests in accordance with standard NF EN 257 (Mechanical thermostats for gas appliances). This bench enables the operator to carry out a series of programmable cycles via a PC, on which the thermostat switching values are automatically archived in the form of a usable Excel spreadsheet.

The software will also list any faults identified during the test (edges, temperature ranges outside tolerance, etc.).

The hydraulic circuit, pressurised to around 1 bar, contains a very small volume of water (≈ 3 l.) to optimise thermal inertia, and a circulator is present in the circuit to ensure temperature uniformity. A heater is used for heating, while a heat exchanger and a cooling unit cool the test loop. The advantage of the closed circuit is that there is no hot water splash.

The cyclic temperature test loop can also be used to control and test electronic thermostats or PT 100 temperature sensors.

Tested product

Mechanical thermostat

Mechanical thermostats are devices used to control the temperature of automated systems. They can be used to establish contact or not when the temperature measured exceeds a threshold.

OUR KEY TEST BENCH FOR THESE TESTS Temperature cycling test bench for thermostats THERMOSWITCH

Temperature cycling test bench for thermostats/temperature sensors. Cycling test bench checks heating or cooling ramps

The bench allows simultaneous control of heating and cooling ramps of 10 mechanical thermostats. It allows to make series of cycles programmable by PC.

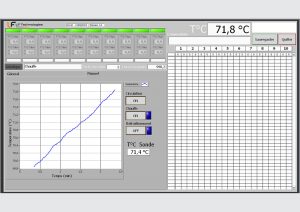

The switching temperature of the thermostats is automatically indicated on both the up and down sides for each thermostat.

The switching values of the thermostats are archived in the form of a table that can be used in Excel.

A display shows the temperature slopes and the status of each thermostat, as well as a table of the recorded switching values.

Bench developed to meet these standards:

NF-EN-257

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.