Endurance test bench for sanitary tapware

- Quick and easy installation of valves of any shape

- Automatic testing without manual intervention

- Automatic shutdown in the event of leakage or abnormal operating torque

- Test reproducibility

Products tested

Sector of activity

Main functions

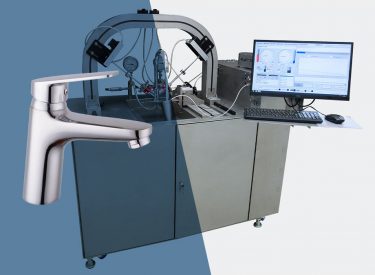

The endurance test bench is a test bench designed to test the service life of taps, mixers, reversers, mechanical and thermostatic mixing valves, fully automatically and in accordance with NF, EN, ASSE etc. standards.

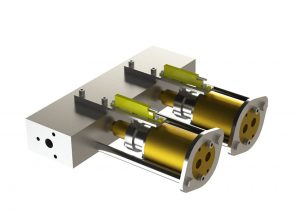

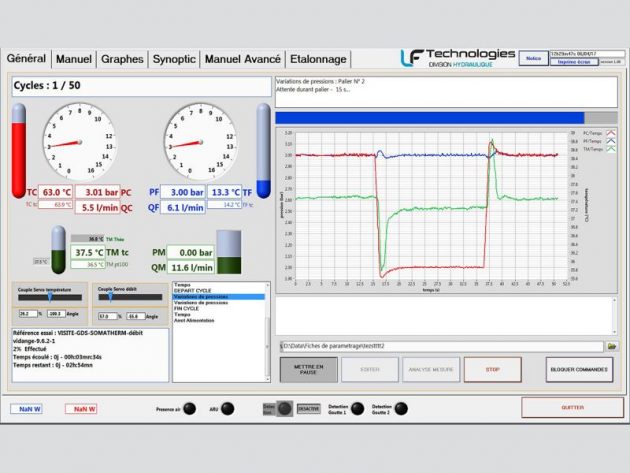

The machine is equipped with an automated measurement system that assesses the valve’s reliability during its endurance, based on changes in operating torque and tightness.

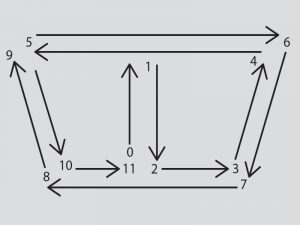

Operating mode

Discover how our endurance test bench for valves works

- Mounting the valve to be tested on the central board ;

- Setting the valve position ;

- Assembly of actuators for motion control (rotation or translation) ;

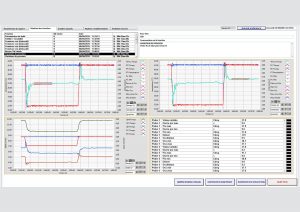

- Programming tests on the control screen ;

- Scenario startup.

Device features

- All-stainless steel chassis

- PC control

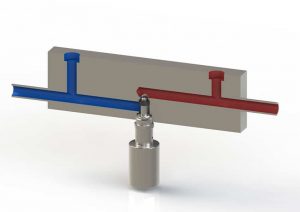

- Pressure control 0.1 to 6 bar ± 0.05 bar

- Flow 2x 25 l/min

- Automatic leak detection

- Operating force/torque 100 N, 6 Nm

- Closed enclosure for protection against splashing water

Bench developed to meet these standards:

Mitigeurs Thermostatiques EN1111

Thermostatic mixing valves EN1111

Mitigeur mécanique monocommande – EN817

Single-lever mechanical mixing valve - EN817

Robinet temporisé EN816

Timer valve EN816

Essai endurance selon norme EN816

Endurance test in accordance with EN816

Enceinte fermée

Closed enclosure providing protection against potential water splashes.

Cycle d’endurance standard mitigeurs mécaniques

Standard endurance cycle for mechanical mixers

Life-Multi-Delabie

Banc d'endurance pour robinetterie - client : DELABIE - LF Technologies

Life-Multi-Delabie-zoom

Zoom sur robinet et actionneur - Banc d'endurance pour robinetterie - client : DELABIE - LF Technologies

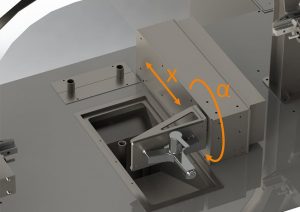

Endurance of a Mechanical Mixer Tap

Automated movement of a mechanical mixer tap using two actuators. A rotary actuator for temperature control and a linear actuator for flow control.

Advantages of LifeMulti

Simple assembly

Quick and easy installation of valves of any shape

Automatic shutdown

Automatic shutdown in the event of leakage or abnormal operating torque.

PC control

Simple test initiation and follow-up via PC control.

TECHNICAL CHARACTERISTICS of the Endurance Test Bench for Valves and Fittings

Spécifications | LifeMulti |

Performances hydrauliques | |

Débit EC et EF | 0-25 l/min |

Pression EC et EF | 0-6 bar |

Mesure de pression | ± 0,01 bar |

Débitmètrie EC, EF, EM | ± 0,1 l/min |

Performances thermiques | |

Plage de température (selon source) | 5-75° C |

Mesure de température EC, EF, EM | ± 0,2° C |

Performances mécaniques | |

Actionneur rotatif | |

Couple max. dans les 2 sens | 6 N.m |

Vitesse max. dans les 2 sens | 180°/s |

Résolution de la mesure de couple | 0,01 N.m |

Résolution de la mesure de position angulaire | 0,1° |

Angle de rotation max | illimité |

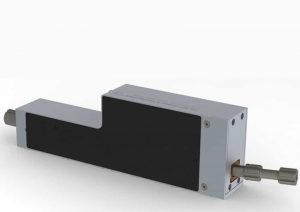

Actionneur linéaire | |

Force max. dans les 2 sens | 100 N |

Course max | 125 mm |

Vitesse max | <40 mm/s |

Précision de la mesure de force | ± 0,1 N |

Précision de la mesure de position | ± 0,02 mm |

Dimensions d'un poste | |

Largeur | 550 mm |

Profondeur | 650 mm |

Hauteur | 2 100 mm |

Poids | ≈170 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test