Hydraulic Test Benches for Taps and mixers

- Quick and easy installation of valves of any shape

- Automatic testing without manual intervention

- Test reproducibility

- Standard tests according to NF, EN, ASSE, NHS standards

Products tested

Sector of activity

Main functions

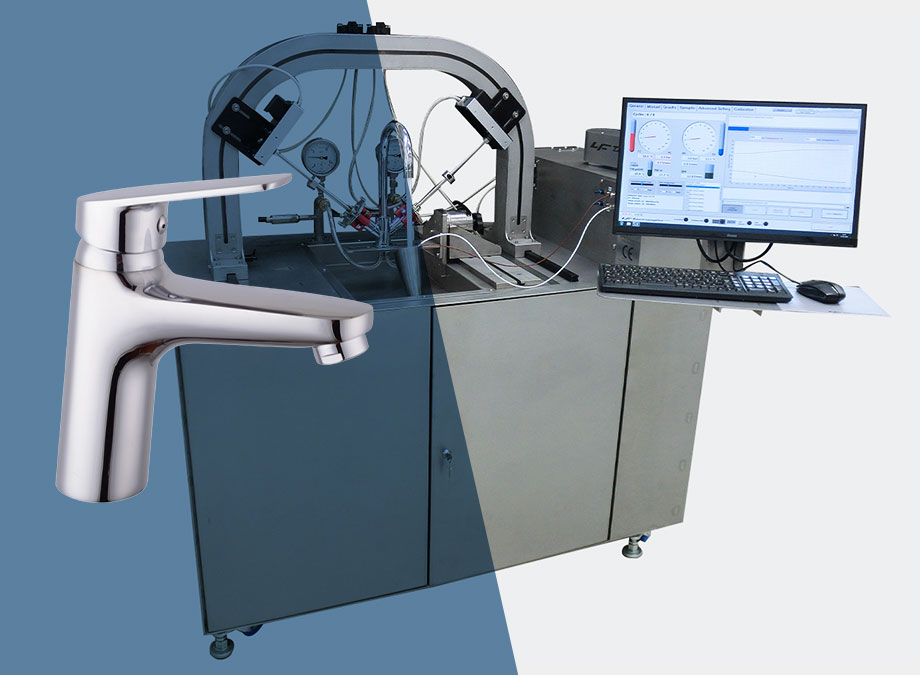

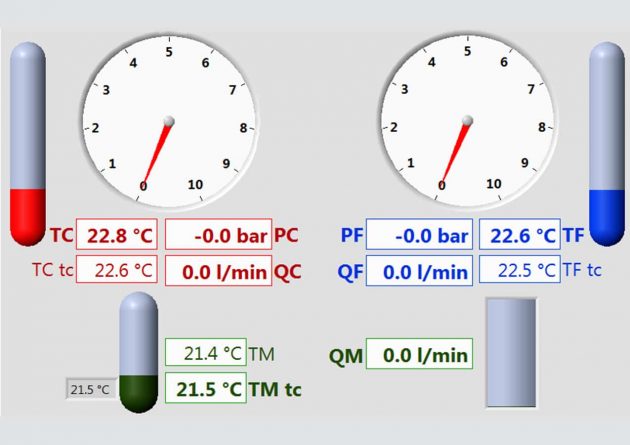

The performance test bench for mixing and mixing valves is a test bench designed to measure the performance of valves and fittings using measuring instruments. The station is used to test the mechanical strength and hydraulic characteristics of mechanical and thermostatic mixing and mixing valves.

This test bench can be used by :

- R&D for design ;

- production for series testing;

- the laboratory for characterization, qualification and compliance with standards.

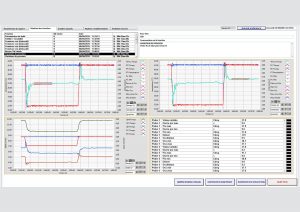

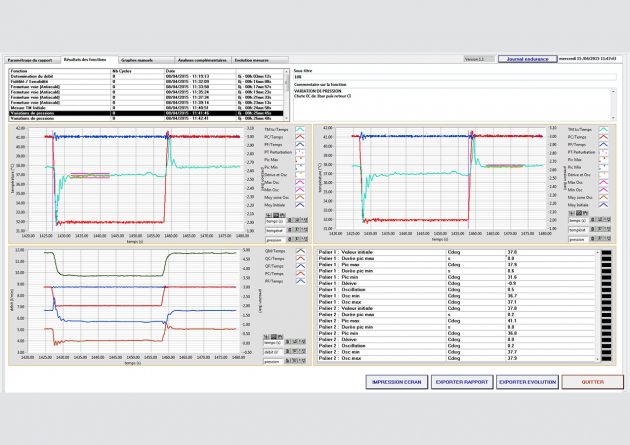

Our valve test benches are designed on a modular basis, and can be equipped with software to automate testing, to control measuring instruments, to carry out standardized tests autonomously, and to deliver a documented report. The software is responsible for chaining test scenarios (flow and temperature settings, test sequences according to standards, etc.), recording measurement results, performing calculations and editing a results report.

Operating mode

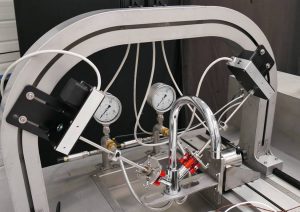

The test bench generates pressure using slave pumps, and controls the movement of control levers for taps, mixers and mixing valves using motorized actuators. These actuators are mounted on a C-beam which allows flexible attachment of all types of valve. When the devices to be tested are positioned on the test bench, pre-programmed test scenarios are run to measure pressures, flows, positions, torque and operating force.

Device features

- Test device orientation and positioning plate

- Automatic actuators for all types of valves

- All-stainless steel chassis

- PC control

Technical specifications

- Operation of self-learning servo controls

- Closed-loop pressure generation (Hot water, Cold water) from 0 to 6 bar (± 0.05) from 0 to 2×25 l/min

- Instant pressure variation by programming

- Operation force and torque 100 N; 6 Nm

- Automatic integration of test standards into software

- Automatic redaction and editing of test reports according to selected standards

- Archiving and data transmission

- Optimization of water recovery (hot-cold)

Mitigeur mécanique

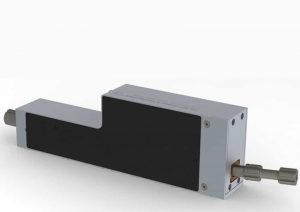

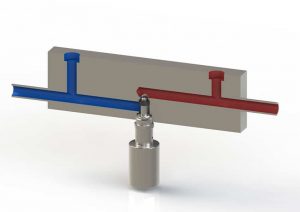

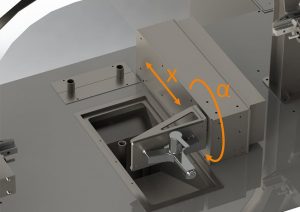

Linear and rotary actuators adjust flow rates and temperatures.

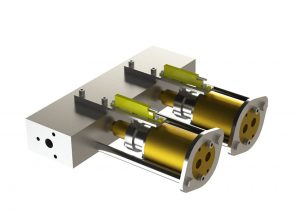

Mitigeur thermostatique

Two rotary actuators are positioned on the thermostatic mixing valves to initiate a complete test in accordance with NF3 standards.

Montage simple

Positioning the valves on the actuators is quick and easy.

Banc de test hydraulique pour robinetterie sanitaire

Hydraulic test bench for sanitary fittings

Endurance mechanical mixing valve

Endurance test of a mechanical mixing valve to NF077 standard. The mixer’s movement is achieved by a computer-controlled synchronized rotary actuator and linear actuator.

Perf-Valve benefits

Bench flexibility

The performance bench can be adapted to a wide range of valves, thus broadening the spectrum of products to be tested.

Automatic reports

Automatically write and edit test reports according to selected standards.

Automatic tests

Tests are performed automatically, with no manual intervention required.

TECHNICAL SPECIFICATIONS of the Performance Bench for Faucets and Mixers

Spécification | Perf-Valve |

Performances Hydrauliques | |

Débit EC et EF | 0-25 L/min |

Pression EC et EF | 0-6 bar |

Mesure de pression | ± 0,01 bar |

Débitmètrie EC, EF, EM | ± 0,1 l/min |

Régulation de pression EC et EF | ± 0,05 bar |

Performances Thermiques | |

Mesure de température EC, EF, EM | ± 0,2° C |

Performances Mécaniques | |

Actionneur rotatif | |

Couple max. dans les 2 sens | 6 N.m |

Vitesse max. dans les 2 sens | 180°/s |

Résolution de la mesure de couple | 0,01 N.m |

Résolution de la mesure de position angulaire | 0,1° |

Angle de rotation max | illimité |

Actionneur linéaire | |

Force max. dans les 2 sens | 100 N |

Course max | 125 mm |

Vitesse max | <40 mm/s |

Précision de la mesure de force | ± 0,1 N |

Précision de la mesure de position | ± 0,02 mm |

Dimension du Poste | |

Largeur | 1 400 mm |

Profondeur | 800 mm |

Hauteur | 1 500 mm |

Poids | ≈250 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test