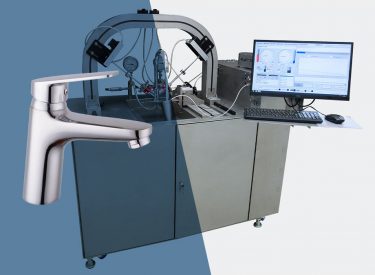

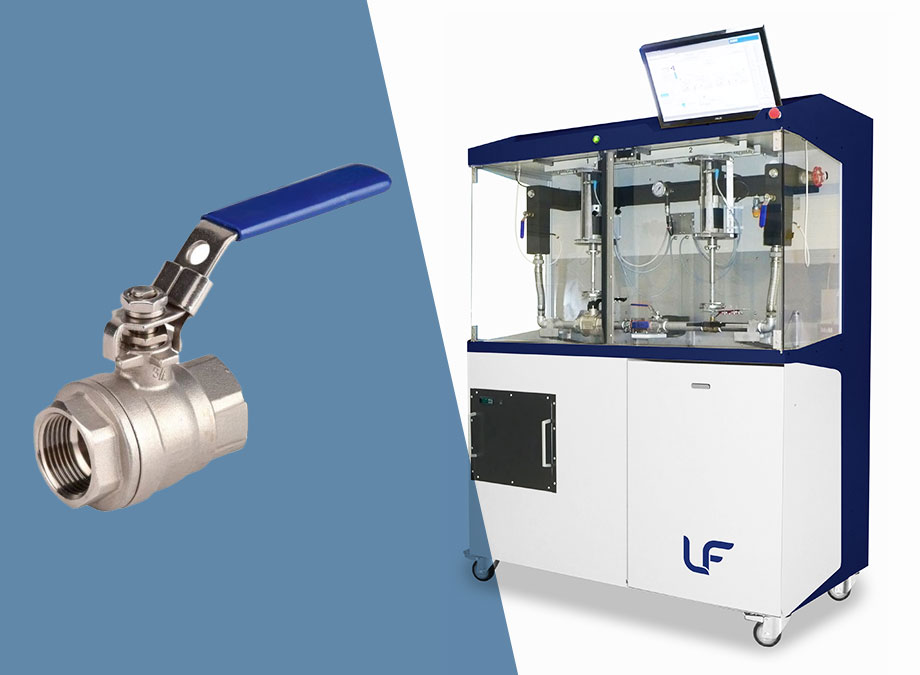

Endurance test bench for ball valves (RTS)

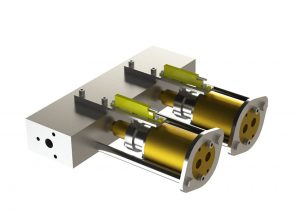

The endurance test bench for ball valves (RTS) tests the resistance of valves and ball valves subjected to high torques and extreme temperature variations. It guarantees the reliability of valves through automated and reproducible tests that comply with standards.

Products tested

Sector of activity

Main functions

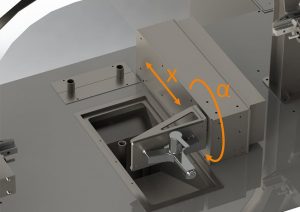

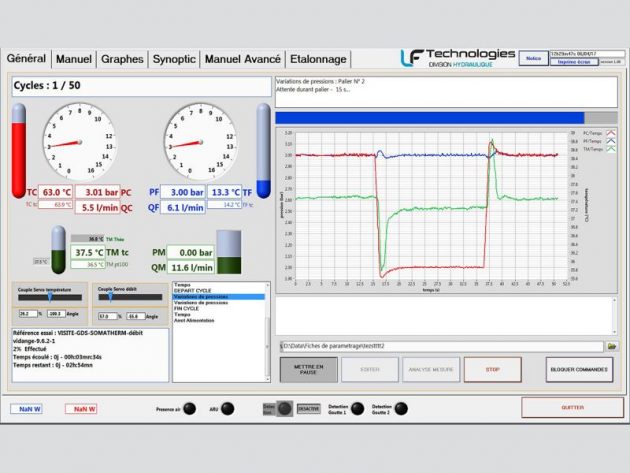

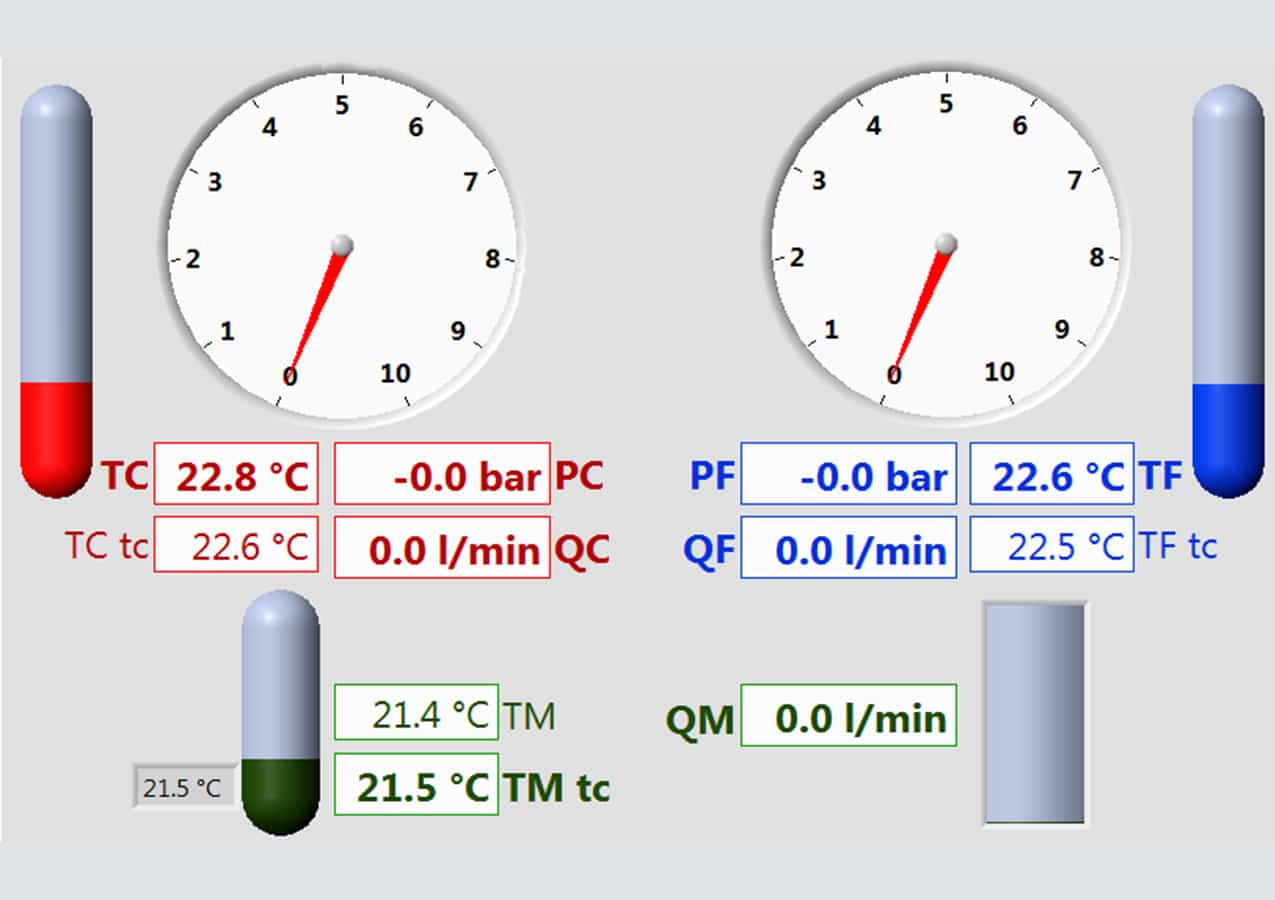

The endurance test bench for ball valves is designed to simulate real-world conditions for ball valves and taps by subjecting components to extreme torsion and temperature cycles. Its advanced automation allows for precise test control and optimal test repeatability.

Key features :

- Application of high torques up to 100 Nm to test mechanical strength.

- Thermal simulation from -5°C to +110°C to reproduce extreme conditions.

- Execution of programmable test cycles.

- Automated control with precise regulation of torque, temperature, flow rate, and pressure.

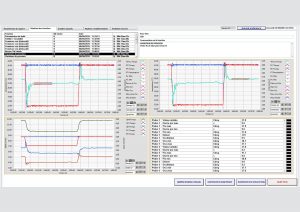

- Real-time data acquisition and analysis for complete traceability.

Operating mode

The endurance test bench for RTS operates by subjecting ball valves and rotary valves to repetitive torsion cycles under controlled temperatures.

- Test preparation:

- Installation of the valve on the bench.

- Configuration of parameters: torque, temperature, flow rate, pressure, number of cycles.

- Cycle execution:

- Closing/opening of the torque-controlled tap.

- Exposure to a controlled fluid temperature between -5°C and +110°C.

- Automatic cycle sequencing.

- Analysis of results:

- Real-time data recording.

- Detection of anomalies (loss of tightness, deformation, breakage).

- Generation of automated reports.

Bench developed to meet these standards:

EN-13828

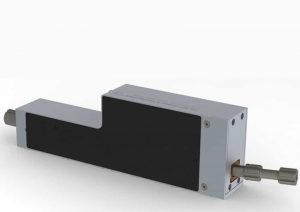

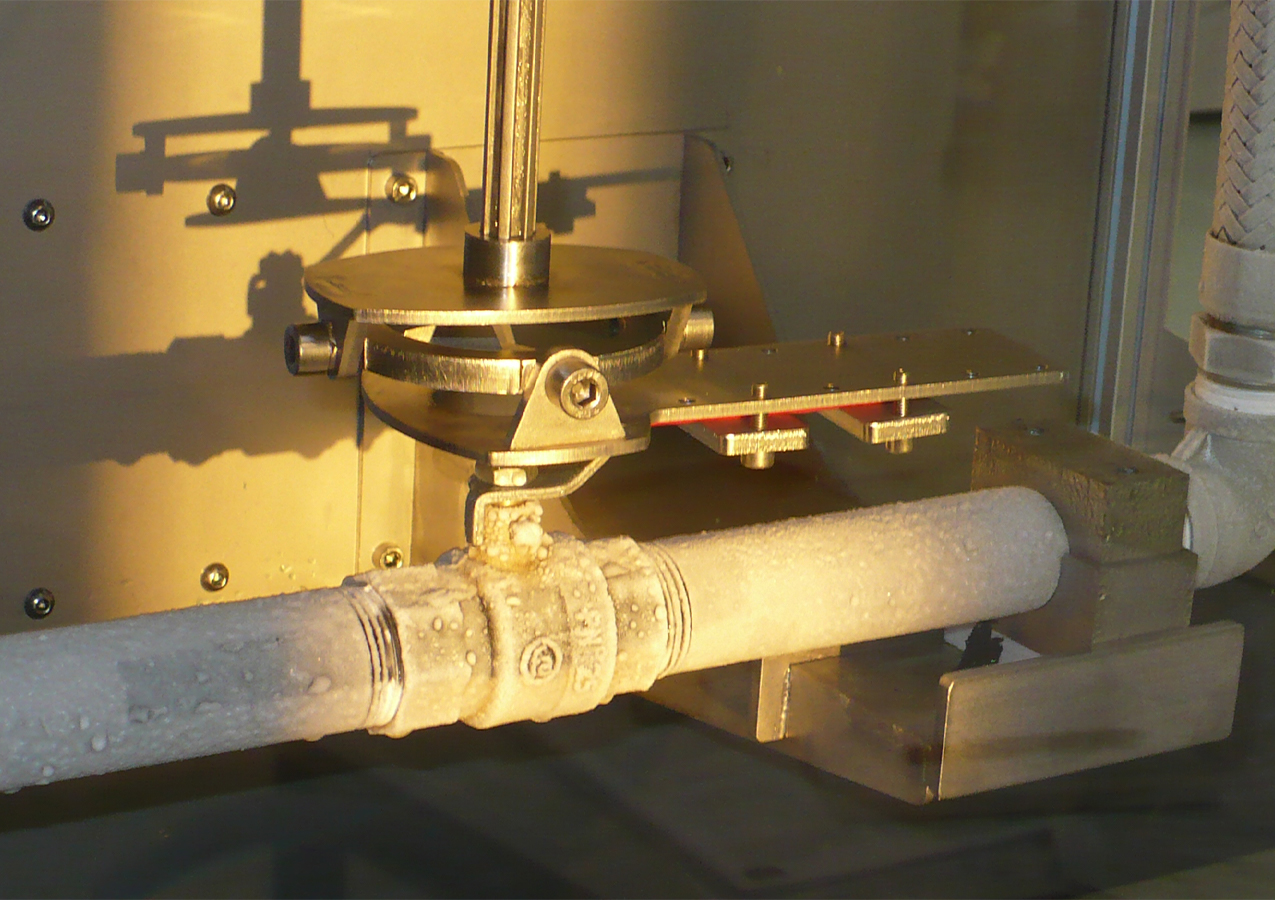

Banc-d’endurance-couple-fort-chaud_froid-zoom

Banc d'endurance pour RTS - EN13828

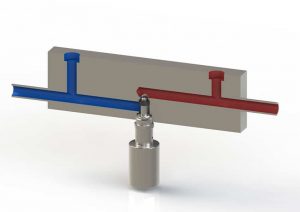

Banc-d’endurance-couple-fort-chaud_froid

Banc d'endurance pour RTS - robinets à tournants spéhriques - EN13828

Zone de test couple fort chaud/froid

High torque hot/cold test zone

Test chaud froid sur robinet

Hot Cold Tap Test

Benefits of Life-RTS

- Tests compliant with standards NF EN 13828 and NF 079 Doctech 09

- Optimal precision

- Full automation

- Real-time analysis

Tests compliant with standards NF EN 13828 and NF 079 Doctech 09

Accurate simulation of mechanical and thermal stresses.

Optimal precision

Precise control of torque (±1%) and temperature (±0.5°C).

Full automation

Reduced human intervention and guaranteed reproducibility.

Real-time analysis

Continuous data acquisition and detailed reporting.

TECHNICAL SPECIFICATIONS of the Endurance Test Bench for RTS

Specifications | LIFE-RTS |

Tested products | Ball valves and rotary ball valves (RTS) / Plug valves / Ball valves |

Maximum torque | 100 Nm |

Temperature range | -5°C to +110°C |

Temperature accuracy | ± 0,5°C |

Cycle time | Adjustable |

Data acquisition | Real-time recording |

Automation | Programming and monitoring of tests |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test