Pressure generation bench for pipelines

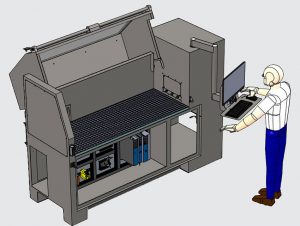

The pipe pressure test rig is a hydrostatic test rig designed to apply cyclic and static pressure. A dedicated circuit also allows the simulation of water hammer.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is the world’s leading expert in water and waste management. It puts its capacity for innovation at the service of sustainable resource management.

Main functions

Objective

Check that the product is in good condition and that there is no deterioration of the product (leakage, breakage, etc), check if the pipe can resist to pressure and thermal shocks, for its entire lifetime.

Apply cyclic and static pressure of up to 25 bar and 450 bar to sewer pipes.

And Aries strokes of up to 50 bar.

PROBLEMATIC ISSUES

Simulate water hammer in a large-diameter pipe.

Water hammer is a phenomenon that occurs when a quantity of water moves at high speed through a pipe and is stopped dead in its tracks (by the closure of a valve, for example). As the moving water has accumulated kinetic energy, this energy must be dissipated. The dissipation of this energy takes the form of a shock in the pipe.

To simulate this phenomenon in the laboratory, you need to generate a sharp, configurable increase in pressure (depending on the pipes being tested: plastic, cast iron, etc.).

SOLUTION AND RESULT

The proposed solution is a bench allowing both cyclic and static pressure to be applied.

It is equipped with an autonomous power supply system. This means the machine can be used without permanent connection to a supply and discharge network.

The equipment comprises several test circuits. Each circuit can be drained and pressure tested.

Circuit for cyclic pressure testing up to 25 bar

Circuit for cyclic and burst tests up to 450 bar

Water hammer circuit up to 50 bar.

Each circuit is pressurized by a motorized plunger which compresses the water in the circuit. The displacement of the pressure generator piston gives a volume measurement. A sudden change in this volume measurement allows the detection of a leak or burst.

Test procedure :

The tested product is placed in the sink. It is connected to the appropriate test circuit.

Once the product has been filled and purged, the static pressure generator applies the programmed pressure according to a predefined profile.

The bench measures, displays and records the pressure and volume curves obtained.

If a leak is detected, the test stops automatically.

Water hammer :

To simulate water hammer, the pressure must be built up quickly. This pressure peak requires energy. In reality, this energy corresponds to the kinetic energy of moving water (with a large mass corresponding to a long length of pipe).

At the level of the pipe under test, this kinetic energy is converted into pipe deformation energy. This corresponds to the product of the increase in pressure and the delta in volume (expansion of the pipe).

Tested product

Piping systems

A pipeline is made up of pipes used to carry a fluid from point A to point B.

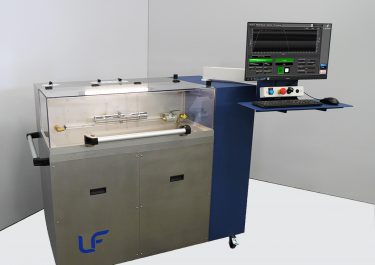

OUR KEY TEST BENCH FOR THESE TESTS static and cyclic pressure test bench LIFETUBE

Main functions

This test bench is designed to perform cyclic pressure tests in water, on one or more products simultaneously. It simulates water hammer in piping systems, or tests (accelerated) aging of components. It checks for leaks by pressure drop or flow detection. It can also be used to carry out pressure tests on components subject to specific legislation.

The shape of the stress curves can be set. The number of test cycles and their sequence are programmable.

The air purge is automatic and verified by the system stiffness measurement.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.