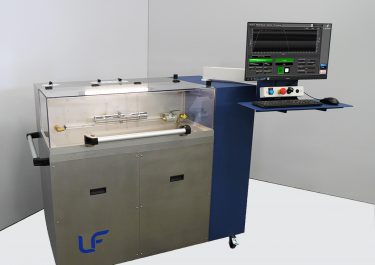

Zone-Valves endurance bench

Endurance bench designed to test the heating element of a zone valve. The bench can accommodate 20 stations simultaneously.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Endurance testing of the zone valves in a cycle of heating (blowing hot air) and then cooling by forced air. he tests are performed on the heating elements present in the valve actuators.

PROBLEMATIC ISSUES

The bench consists of 20 modules that must be able to operate simultaneously and independently of each other.

Solution and Result

The endurance bench built by the LF Technologies teams comprises a set of 20 stations that can test as many parts simultaneously. These units are all mounted on a frame, which contains both a cold air loop (from 15°C to 25°C) and a hot air loop (from 25°C to 60°C). Fans circulate the air in the chambers to even out the temperature. A hatch allows hot and cold air to flow between the casings and the modules; Within a module, the air circulates around the actuator and then returns to the main plenum.

The valve zones to be tested are connected to terminal blocks (on the modules) which power them according to the selected programme and the phases of the endurance cycle set.

Each module is fitted with a displacement sensor to measure the position of the sensitive element. The modules are also equipped with an input/output interface block that communicates via a network with the control PC. This technology offers the advantage of being able to interface a large number of sensors/actuators with simple connectors, as well as being able to easily add inputs and outputs in the future.

Each of the stations is supplied with a tool for positioning the part to be tested in the air flow, providing several functions such as displacement measurement, quick change of a stress spring or adjustment of the spring preload.

To ensure the safety of operators, the bench is equipped with 3 emergency stops enabling the active parts to be de-energised (hatches, cooling unit, fan, heating resistors and power supply for sensitive elements).

TESTED PRODUCT

"zone valve" (zone valve / diverter valve)

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.