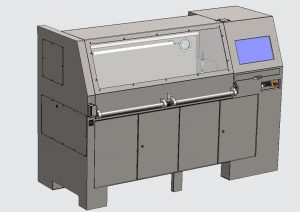

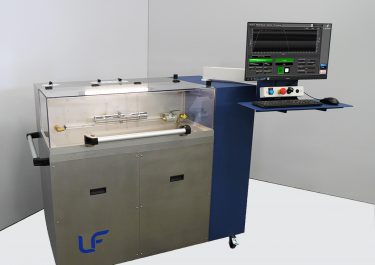

Pressure cycle test bench

Cyclic pressure test rig for simulating water hammer in pipes. Leak testing by pressure drop or flow detection.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Our customer wants to test the resistance of its products to internal hydraulic pressure. The purpose of this test bench is to test the mechanical fatigue and tightness of valve components subjected to sudden variations in pressure.

Problematic issues

Such tests often require a great deal of energy and hydraulic power. This test bench has to reach very high or very low pressure levels without wasting energy.

Rapid pressure variations in large components require very high hydraulic power. Our first challenge is to design an energy-efficient system that recovers the elastic energy of the product under test.

In addition, the system must be capable of ensuring high accuracy of high and low pressure levels, whatever the dimensional variations of the product under test.

Solution and result

Conventional pump + solenoid valve systems do not allow energy recovery.

Motorised plungers require far too much instantaneous power.

The study carried out by our engineers showed that a variable displacement pump was the ideal solution for :

- Check pressure rises and falls, whatever the pressure or volume of water

- Recover energy and reduce power consumption.

The bench is designed to perform cyclic pressure tests in water on one or more products simultaneously. It simulates water hammer in pipes or tests the ageing of components.

The proposed principle allows :

- perfect control of pressure rise and fall ramps, whatever the variation in volume and the high and low pressure thresholds

- recovery of expansion energy, enabling a considerable reduction in installed power (up to 90% in some cases)

- pressure-controlled cycles up to a frequency of 1 Hz.

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

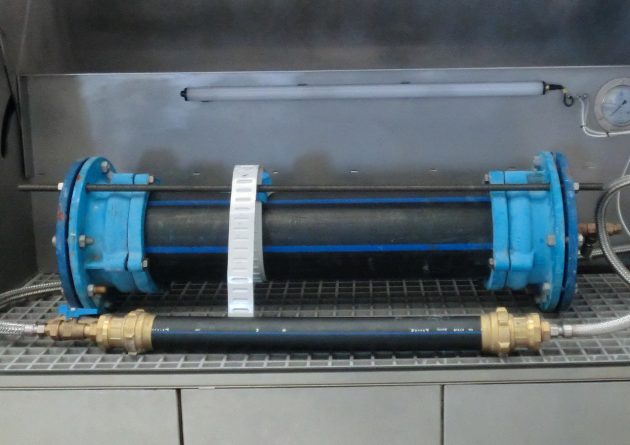

Closing collar

Fittings mainly made of copper alloy, such as PE pipe fittings and shut-off collars

Pipe fittings are plumbing components used to join elements together to ensure a watertight connection.

In this case, the clamps are used to connect a tap or branch to a drinking water distribution pipe.

PE pipe fitting

Fittings mainly made of copper alloy, such as PE pipe fittings and shut-off collars

Pipe fittings are plumbing components used to join elements together to ensure a watertight connection.

In this case, the clamps are used to connect a tap or branch to a drinking water distribution pipe.

OUR KEY TEST BENCH FOR THESE TESTS static and cyclic pressure test bench for pipes and ducts LIFETUBE

This test bench is designed to perform cyclic pressure tests in water.

Main functions

This test bench is designed to perform cyclic pressure tests in water, on one or more products simultaneously. It simulates water hammer in pipes or tests the ageing (in accelerated mode) of components. It checks for leaks by pressure drop or flow detection. It can also be used to perform pressure tests on components subject to special legislation.

The shape of the stress curves can be set. The number of test cycles and their sequence are programmable.

The air purge is automatic and verified by the system stiffness measurement.

Operating mode

The purpose of a test is to apply static pressure cycles, according to a trapezoidal profile, in a more or less elastic product.

- Installation and clamping of the sample

- Connecting the supply hose and purge hose

- Setting up the software / selecting the program

- Start of the test scenario

- Automatic purging, controlled cycling, automatic leakage monitoring

- Recording of test results

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.