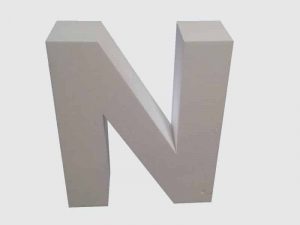

Cutting shapes and lettering from lightweight materials using abrasive wire

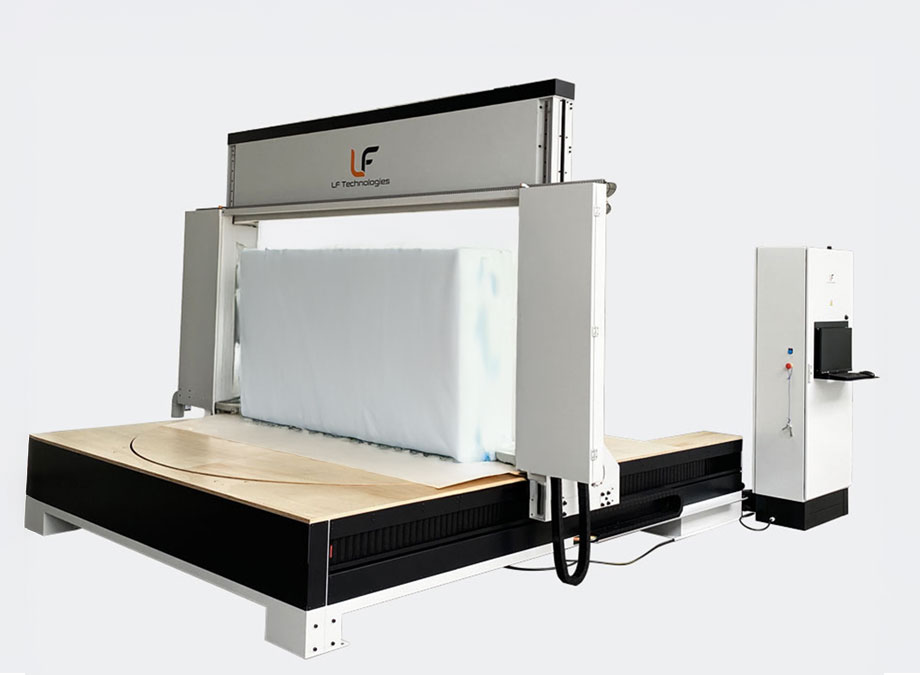

In signage, advertising and visual decoration, precision and speed make all the difference. Conventional cutting methods leave thick edges, mark the material and struggle with fine geometries. To remedy this, LF Technologies has designed an abrasive wire cutting machine with a rotating table: clean contours, tight radii, minimal finishing, compatible with customised and small series production, for higher quality and productivity.

THE SOLUTION PROVIDED BYLF TECHNOLOGIES

In signage, advertising and visual decoration, the creation of original shapes, letters, logos and signs is a major challenge.

These elements must be:

- Aesthetic and precise,

- Suitable for bespoke solutions,

- Produced quickly, often in small batches or as one-off pieces.

Conventional cutting methods (thermal blade, jigsaw, mechanical CNC) have limitations:

- Thick or irregular cut marks,

- Risks of burns or crushing of materials,

- Difficulties in following complex geometries,

- Significant machining or finishing time.

A manufacturer of signs and point-of-sale advertising approached LF Technologies to improve its visual quality and productivity.

Processed products

Polystyrene (EPS/XPS) and other foams

Expressed need

- Create letters, logos and decorative shapes with great finesse.

- Ability to cut various lightweight materials (foam, polystyrene, composite panels).

- Reduce manufacturing times to meet tight deadlines.

- Achieve a flawless finish without the need for touch-ups.

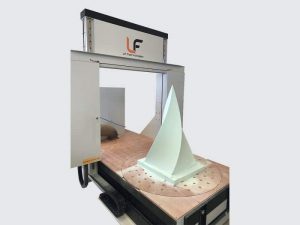

Proposed solution – MO-D-FIL machine

LF Technologies has deployed the abrasive wire cutting solution, which is perfectly suited to advertising applications:

- 360° free cutting on a turntable, enabling the creation of logos, letters and complex shapes.

- High cutting precision for clean, attractive finishes.

- Simplified programming: import and execution of vector or custom shapes.

- Cutting without mechanical stress: no crushing or burrs, ideal for light and fragile materials.

- Total flexibility: rapid prototyping, small or medium-sized production runs.

Results achieved

- Premium visual quality: clean outlines, suitable for displays and presentations.

- Speed: significant reduction in cutting time (up to 35%).

- Versatility: possibility of producing both unique pieces and series.

- Reduced reworking: removal of burrs and direct improvement in the final appearance.

Sectors & outlook

This application is ideal for those involved in visual communication and advertising:

- Illuminated signs, letters and logos,

- Advertising panels, point-of-sale advertising, displays,

- Decorations for trade fairs and events,

- Indoor and outdoor signage.

It combines creativity, speed and high-end finishing, meeting the expectations of the advertising and visual communication market.

Sandrine H.

Workshop Manager Signage & POS advertising company

With our abrasive wire cutting machine, we produce custom lettering and logos in record time, with impeccable visual quality. Our customers are impressed by the fineness of the cuts.

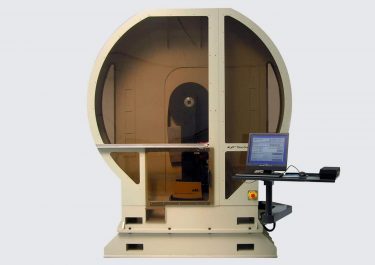

Our key machine Abrasive wire cutting machine on a rotating table MO-D-FIL

Functionality

High-speed abrasive wire cutting of materials;

This cutting technique makes it possible to cut a large number of different materials, particularly flexible materials, with virtually no cutting effort; Abrasive wire cutting allows cuts to be made with a very fine “saw cut” and without a preferential direction (possibility of cutting in all directions).

Technology

- Turntable for 360° cutting

- Automatic optimization of the feed speed according to the cutting force

- Optimisation of the feed speed according to the bending radius and change of direction

- Automatic wire breakage detection

Bench developed to meet these standards:

Abrasive wire cutting – MO-D-FIL

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.