Cutting insulating materials with abrasive wire

High-speed abrasive wire cutting allows a wide variety of materials to be machined, including the most flexible ones, with virtually no cutting effort. It produces an extremely fine cut and does not impose any preferred direction, offering complete freedom of movement to cut in all directions.

THE SOLUTION PROVIDED BYLF TECHNOLOGIES

In the construction industry, the use of thermal insulation materials and

Acoustic materials (foam, mineral wool, composite panels) require cutting

accurate, fast and clean.

Traditional methods (hand saws, thermal cutting, vibrating blades)

often generate :

- dust and smudges,

- material losses,

- difficulties in obtaining complex shapes,

- significant machining times.

An industrial company specialising in the manufacture of insulation solutions for façades and roofs has

approached LF Technologies to improve its cutting process.

Processed products

Insulation - Glass wool

Glass wool is a mineral insulation material made from sand and recycled glass, which are transformed into fibres. It offers excellent thermal and acoustic performance, while being lightweight, non-combustible and durable. Used in rolls, panels or flakes, it insulates walls, attics, roofs and partitions in residential and commercial buildings.

Expressed need

- Make straight and diagonal cuts in insulating foam panels.

- Ability to produce specific shapes for particular construction sites (technical passages, recesses, on-site adjustments).

- Reduce material waste and improve cutting quality to limit reworking.

- Ensuring a safer and cleaner working environment.

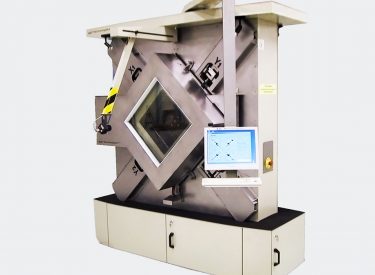

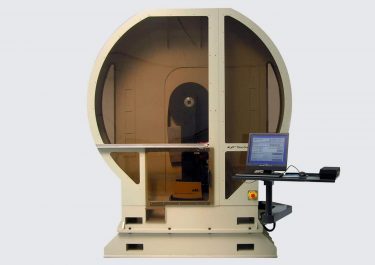

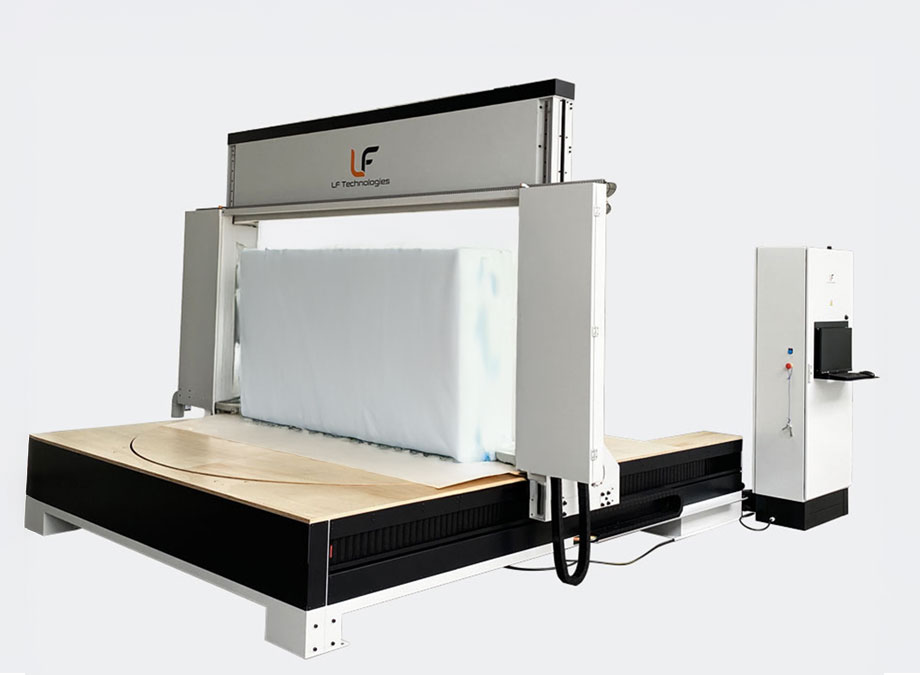

Proposed solution – MO-D-FIL machine

LF Technologies has developed an abrasive wire cutting solution that enables:

- Multidirectional cutting (360°) thanks to the turntable, suitable for free forms.

- Increased precision with a fine, even cut.

- Automatic control of speeds based on cutting effort and changes in direction.

- Low mechanical stress, preserving the integrity of often fragile insulating materials.

- Integrated thread break detection to ensure reliable production.

Results achieved

- Clean cutting quality: elimination of burrs and reduction in manual reworking.

- Productivity gains: cutting time reduced by 25% compared to traditional methods.

- Increased flexibility: ability to respond to customised customer requests (complex parts, special shapes).

- Improved working environment: reduced dust and nuisance for operators.

Sectors & outlook

This application is intended for manufacturers and processors of insulating materials:

- Polyurethane foam panels, expanded or extruded polystyrene,

- Mineral wool (glass, rock),

- Lightweight composite insulators.

It paves the way for flexible industrialisation, suited to both mass production and customised demands.

Alexandre D.

Production Manager Building insulation company

Thanks to the abrasive wire cutting machine, we have gained in precision and speed. We can offer our customers insulation solutions that are perfectly suited to specific projects, while reducing our material costs.

Machine-de-découpe-à-fils-abrasif-sur-laine-de-verre

Mise en route de la machine à découpe à fil sur de la laine de verre

laine-de-verre-en-cours-de-découpe-par-fil-abrasif

Découpage de laine de verre

laine-de-verre-découpée

Bloc de laine de verre découpé de façon précise

image (5)

Coquille isolation - Produit d'isolation découpé

Machine-de-découpe-à-fils-abrasif-pour-isolant-usine

Machine-de-découpe-à-fils-abrasif-pour-isolant-usine

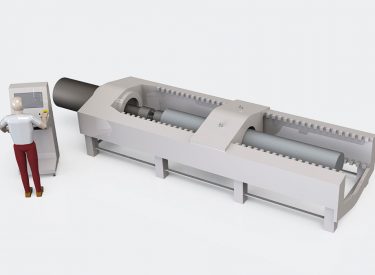

Our key equipment Abrasive wire cutting machine on a rotating table MO-D-FIL

Functionality

High-speed abrasive wire cutting of materials;

This cutting technique makes it possible to cut a large number of different materials, particularly flexible materials, with virtually no cutting effort; Abrasive wire cutting allows cuts to be made with a very fine “saw cut” and without a preferential direction (possibility of cutting in all directions).

Technology

- Turntable for 360° cutting

- Automatic optimization of the feed speed according to the cutting force

- Optimisation of the feed speed according to the bending radius and change of direction

- Automatic wire breakage detection

Bench developed to meet these standards:

Abrasive wire cutting – MO-D-FIL

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.