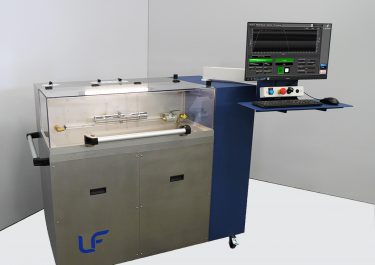

Pressure holding test bench

Pressure test of the boiler circulator. Test bench for pressure resistance, leak test and crash test. Discover our case studies.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

To create a pressure resistance test bench for the entire range of circulators manufactured by our customer. The bench must be able to perform 3 tests:

- Crash test (product’s breakage)

- Pressure holding

- Leak test after customer return

Problematic issues

Design and production of a test bench for carrying out pressure resistance tests on boiler circulators and hydraulic assemblies, with fine pressure control based on configurable pressure profiles. Particular attention is paid to safety.

Solution and result

The test area is positioned on a frame housing the sink that collects the liquid spills. The sample to be tested is connected to the centre of the sink.

The pump body under test is inserted into a closed circuit. To generate a pressure increase, according to a programmed ramp, a plunger piston is inserted into the circuit to reduce the volume and increase the pressure via a servo-control on a pressure sensor.

The pump (circulator) to be tested to destruction is not supplied with electricity.

To protect operators in the event of product rupture, the test area is fitted with polycarbonate enclosures and doors. A safety pressure switch prevents pressure exceeding 3.5 bar when the doors are open and locks the doors when the pressure exceeds the pressure switch threshold. An emergency stop button and watchdog stop the test immediately.

The pressure data measured during the test phases is saved in spreadsheet format in a text file. They can easily be processed using Excel-type software.

The pressure test bench is used to characterise the product to detect leaks and measure its burst pressure, up to 60 bar. In this way, customers can improve their product based on the results obtained.

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

Boiler circulators

Crash test on boiler circulators

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.