Subsea Embedded Systems

For your Subsea applications, we design tailor-made systems to integrate various functions in a watertight submersible housing, with electrical, pneumatic or hydraulic connections and on-board control electronics.

These systems are developed to measure according to your requirements and technical specifications.

This can be a housing integrating a hydraulic or pneumatic circuit, sensors, electrical distribution elements, communication hub, etc.

The principle is to embed standard technologies (sensors, solenoid valves, etc.) controlled by on-board electronics in a pressure-resistant watertight housing.

Examples of systems :

- Electrical distribution box and communication hub: this type of system enables several electrical subsea actuators to be connected. The box distributes power supply connections, electrical protection functions and a “Hub” function for communication.

- DC voltage management/adaptor box : box integrating voltage converter, bus voltage limitation systems and load resistor.

- Fluid circuit: system incorporating a hydraulic or pneumatic circuit equipped with sensors (pressure, flow, temperature) and actuators (solenoid valves, valves, flaps, etc.), all controlled by integrated, autonomous, communicating electronics.

- Adaptation box : adaptation of electrical connections or communication protocols.

Examples of applications:

Fluid management circuit

Fluid management circuit (air and water) for emptying/filling/adjusting functions of a ballast system.

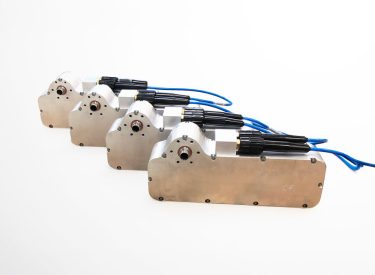

control box

control box for pneumatic circuit integrating flow sensor, pressure solenoid valves.

Validation & tests :

All submarine modules developed by LF Technologies are fully tested in-house, eliminating the need for additional tests:

- Full functional tests: tests carried out in air and in immersion under real load;

- Rigorous tightness tests: validation of tightness up to maximum permissible pressure.

- Verification of communication protocols: checks that the protocol chosen by the customer is operating correctly (CAN, RS232, RS485, Ethernet TCP, Ethernet UDP, Modbus TCP, protocols on request).

- Full energy analysis: measurement of current and power consumption according to several usage scenarios.

Equipement embarqués Susbea

Subsea Watertight Onboard System

Equipement subsea – système embarqué

On-board watertight system for submersibles

Circuit de gestion des fluides – Equipement étanche Subsea

Fluid management circuit - Subsea watertight equipment

Test de système étanche subsea

Subsea onboard system tested in real conditions

Système embarques étanche Susbea

On-board watertight system to manage ballast emptying and filling

Equipement-embarques-èsusbea

SUBSEA on-board systems

You have a porject ?

I will be happy to advise you and propose solutions tailored to your needs.

Thibault Marchand

Subsea Division