Valve leak test bench

High-precision air tightness testing for valves

- Accurate leak detection through micro-flow measurement

- Automated and reproducible tests

- Intuitive operator interface

- Full traceability of tests

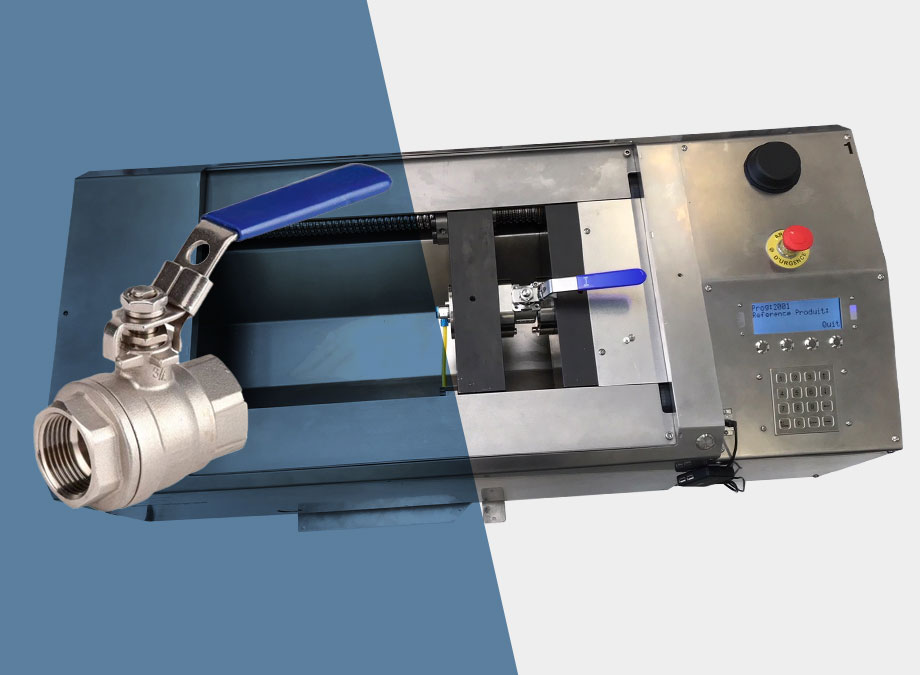

Products tested

Sector of activity

Main functions

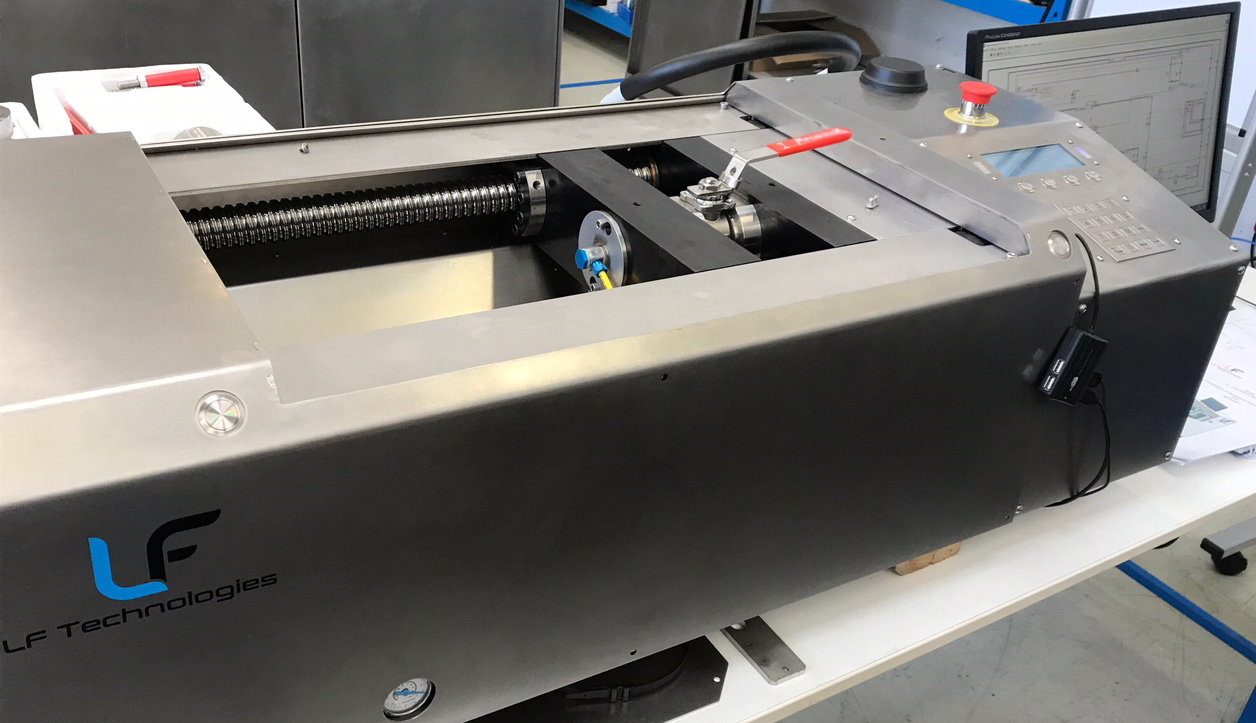

Air tightness test bench for valves. The system grips and clamps the valves, injects air, then measures leaks using micro-flow, with traceability of results.

- Measurement of very low leaks using a digital mass flow meter (micro-flow).

- Clamping controlled by position and force.

- Ergonomics and safety: two-handed control, safe stop if released, emergency stop on front panel.

- Predefined test programmes by valve type, modifiable via control panel or PC (Ethernet).

- Automatic traceability: recording of measurements and report generation.

Operating mode

Discover how our valve air tightness test bench works

The bench holds the valve between two specially designed tools, clamps it automatically, then injects air and measures the leak. The operator controls the test via the bench interface (or from a PC).

Test procedure

- The operator selects the programme corresponding to the type of valve.

- He installs the tools and then places the valve in the bench.

- The bench moves into position and clamps automatically (with two-hand safety control).

- The bench applies pressure and then measures the leak.

- The bench moves away and returns to its starting position.

How is leakage measured?

After pressurisation, the circuit is isolated. If there is a leak, air must continue to be supplied to the valve: the test bench then measures this micro-flow (very low) with a flow meter, which directly gives the leak rate. A complete test (several measurements depending on the configuration) takes approximately 80 seconds (excluding tool changes and handling).

Bench developed to meet these standards:

Valve tested for tightness | LF Technologies

Leak-RTS - Valve Zoom

Leak-RTS – Air valve test bench | LF Technologies

Air valve test bench - LF Technologies

Control panel| LF Technologies

Control panel for the leak test bench - Leak-RTS | LF Technologies

Leak-RTS | LF Technologies

Air tightness test bench for valves

Valve leak test bench

LF Technologies has designed and manufactured testing equipment dedicated to testing the tightness of high-performance ball valves. The tests are carried out by injecting air, with micro-flow measurement enabling leaks to be detected and quantified with precision.

Advantages of Leak-RTS

- Integrated traceability

- Rapid and repeatable tests

- Optimised operator ergonomics

- Precise leak detection

Integrated traceability

Each test is automatically recorded (programme, part number, pressure, leakage flow rate, date/time, etc.). The results can be exported (USB key/network) and formatted into a PDF report or spreadsheet.

Rapid and repeatable tests

Automated sequences guarantee consistent results, independent of the operator.

Optimised operator ergonomics

Human-machine interface guiding test operations step by step.

Precise leak detection

Accurate measurement of micro-flows for reliable leak testing.

TECHNICAL SPECIFICATIONS of the valve air tightness test bench

Specification | Leak-RTS |

Stroke | ≈ 250 mm |

Maximum axis height of tested component | 80 mm |

Maximum force | 60 kN |

Force application accuracy | 15% above 20,000 N |

Flow meter accuracy | ±0.007 cc/min |

Pressure measurement accuracy | ±0,05 bar |

Maximum permissible weight of tested component | 50 kg (no impact during positioning) |

Overall dimensions (L × W × H, excluding options) | ≈ 800 × 650 × 350 mm |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test