Loop test for valve pressure and heat shock

Types of tests performed:

- Thermal shocks: automated hot/cold water alternation

- Pressure surges: upstream/downstream pressure differential on closed valve

- Endurance: opening/closing cycles with torque measurement

- Final leak test: leak measurement

Products tested

Sector of activity

High pressure & thermal shock testing for industrial valves

The test loop designed by LF Technologies enables valves subjected to high thermal and hydraulic stresses to be tested, qualified and proven. Thanks to a dual loop (hot and cold) combined with a dynamic pressurisation system, the test bench reproduces extreme operating conditions: static pressure up to 270 bar, temperature up to 280°C, flow rate up to 300 l/min.

This test bench is particularly suitable for critical applications: nuclear, energy, shipbuilding, oil & gas.

Main functions

- Cycled pressure testing up to 270 bar

- Heats up to 280°C / Cools down to 20°C

- Rapid hot/cold alternation for realistic thermal shocks

- Automatic cycling with position and torque control up to 1000 Nm

- Complete recording of test data

Bench structure

- Mechanically welded frame with secure testing area

- Lockable double glass doors (temperature/pressure conditions)

- Patented self-sealing ball joints for adaptation to all types of valves

- Lifting table on castors for easy assembly

Advanced testing system

- 2 hydraulic loops: 1 hot, 1 cold, + common test loop

- 3 servo-motorised syringes for pressure, shock and expansion compensation

- Customised circulators 300 l/min with flow control via variable speed drive

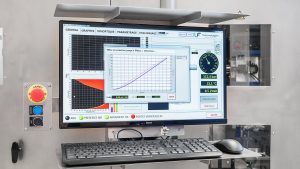

LabVIEW control software

- Manual or automatic control

- Intuitive programming of test sequences

- Real-time display of measurements: pressure, temperature, flow rate, torque

- Automatic reporting and data analysis module (optional)

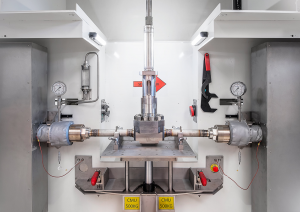

Pressure test loop test zone

Pressure test loop test zone

Pressure control system

Pressure control system

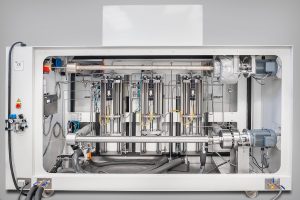

Valve test bench-scaled

Valve test bench

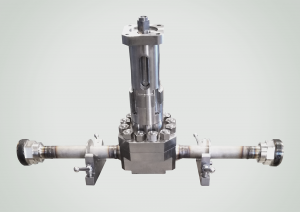

Valve tested

Valve tested

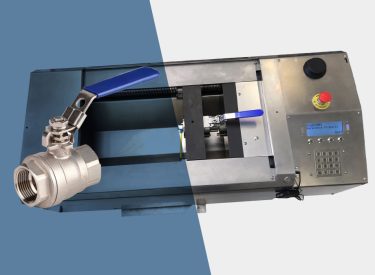

Small valve tested before assembly on the machine

Small valve tested before assembly on the machine

Customised test loop installed on site

Customised test loop installed on site

Test loop test curve

Test loop test curve

TECHNICAL SPECIFICATIONS of the Pressure and Thermal Shock Valve Test Loop

Features | ValveXtreme |

Test fluid | Demineralised water |

Maximum pressure | 270 bar |

Maximum hot loop temperature | 280°C |

Minimum cold loop temperature | 20°C |

Maximum flow rate | 300 l/min |

Useful torque actuator | 5 to 1000 Nm |

Rated power | 40 kW |

Dimensions (W x D x H) | 4000 x 2500 x 2650 mm (approx.) |

Weight | ≈ 4000 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test