Torsion testing on structural parts and mechanical components

Our torsion test bench allows us to accurately test aeronautical mechanical parts subjected to repeated stress. It accurately measures torque, rotation angle and torsional stiffness, even under demanding conditions.

THE SOLUTION PROVIDED BYLF TECHNOLOGIES

Elements such as:

- composite structural components,

- axles and drive shafts,

- fasteners, hinges and ball joints,

- actuators and flight controls,

are subjected to repeated torsional stresses during their life cycle.

Manufacturers must validate the mechanical strength, torsional stiffness and fatigue resistance of these components under extreme conditions (temperature, pressure cycles, dynamic stresses).

An aerospace manufacturer approached LF Technologies to set up a test bench capable of reproducing these stresses and providing accurate, traceable measurements.

Products tested

Elastic coupling/clutch/torque limiter/clamping ring

- Structural components (beams, stringers, fasteners)

- Flight control systems (actuators, ball joints, shafts)

- Engines and transmissions (shafts, couplings)

- Interior fittings (hinges, mechanical systems subject to rotation)

Expressed need

- Measuring the torsional behaviour of composite and metal parts.

- Check the cyclic fatigue of components subjected to repeated torsional stresses.

- Determine the angular stiffness and resistance to breakage.

- Reproduce extreme environmental conditions (temperature, humidity).

- Achieve complete traceability to meet aviation regulatory requirements (EN/ISO, DO, NADCAP).

Solution provided – MBT torsion bench

To meet this need, LF Technologies proposed an advanced configuration of the MBT torsion bench:

- Torque capacity up to 1,000 Nm, adjustable speed up to 400°/min.

- Ensuring accurate measurement, without uncertainty related to inversion.

- High-precision measurement of torque and angle using dedicated sensors (strain gauges + optical encoders).

- Possibility of static or dynamic cycles: monotonic torsion, sine wave, programmed cycle blocks.

- Automatic break detection to secure tests and archive results.

- Comprehensive control software: intuitive sequence programming, real-time acquisition, analysis and automatic report generation.

- Option thermal enclosure (low temperatures, heat build-up).

Results & benefits achieved

- Ergonomics and ease of use: parts can be set up quickly, adjustments are simple, and the control software is very intuitive. This allows users to start tests quickly, limit handling errors, and save time on a daily basis while remaining in a secure and reliable test environment.

- Accuracy and repeatability: reliable measurements thanks to the backlash-free system and high-resolution sensors.

- Time saving: automation of test cycles, shutdown in case of breakage, immediate archiving.

- Regulatory compliance: results that can be used directly in regulatory approvals.

Tanguy F.

Mechanical Testing Manager, Aeronautical company

The torsion bench supplied by LF Technologies allows us to accurately simulate the conditions of use of our aerospace components. Thanks to the precision of the measurements and the automation of the cycles, we have improved our validation speed and enhanced the reliability of our parts.

Torsion Test Bench in Aeronautics | LF Technologies

Torsion Test Bench in Aeronautics | LF Technologies

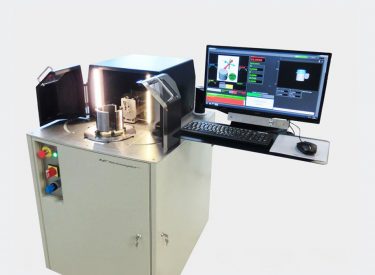

MBT Torsion bench – LF Technologies

MBT Torsion bench - LF Technologies

MBT Torsion bench – LF Technologies – Zoom

MBT Torsion testing machine - LF Technologies - Zoom

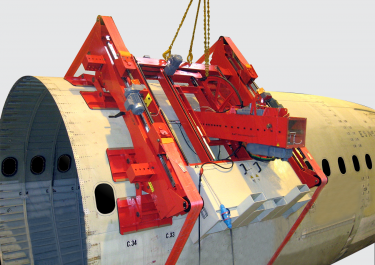

Torsion test bench – Aeronautics | LF Technologies

Torsion test bench - Aeronautics | LF Technologies

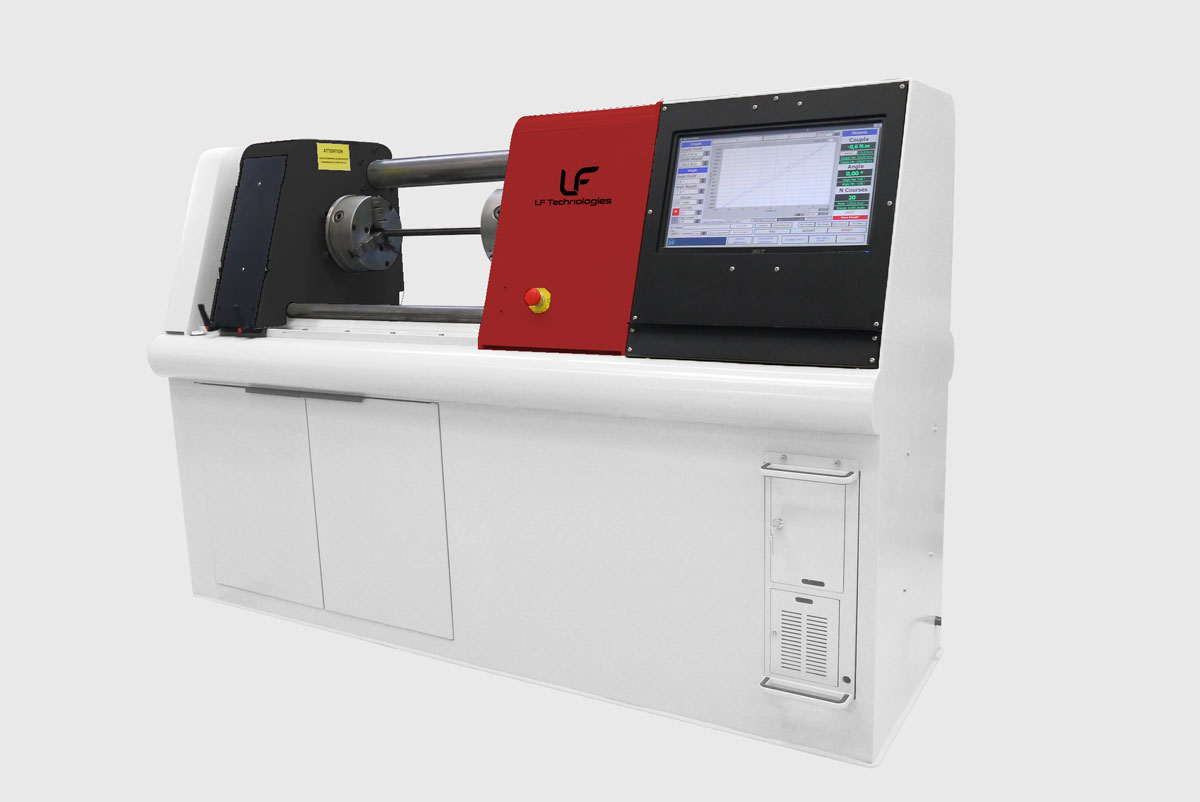

Our key equipment Torsion Bench – MBT

Principle and description

The torsion test bench performs programmable sequences until the parts break, with capacities of up to 1,000 Nm and 400°/min. It automatically calculates torsional stiffness and deformation energy. The test specimens are held on a movable/sliding headstock, allowing variable lengths of up to 500 mm. Torque measurement is based on a strain gauge sensor, while the angle of rotation is measured by a high-resolution encoder.

Operation

The product can be quickly set up using standard interchangeable mandrels. Tests are programmed in automatic cycles using simple parameters, while a backlash compensation device — with double pre-tensioned transmission — ensures zero backlash during operation. The measuring chain offers high angular resolution for accurate readings. Finally, the working length can be adjusted using a sliding head equipped with a brake, allowing the device to be adapted to different part geometries.

Bench developed to meet these standards:

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.