As part of the development of a rocket engine, the customer wanted a comprehensive, flexible and high-performance test bench to carry out mechanical and pressurisation tests according to different profiles.

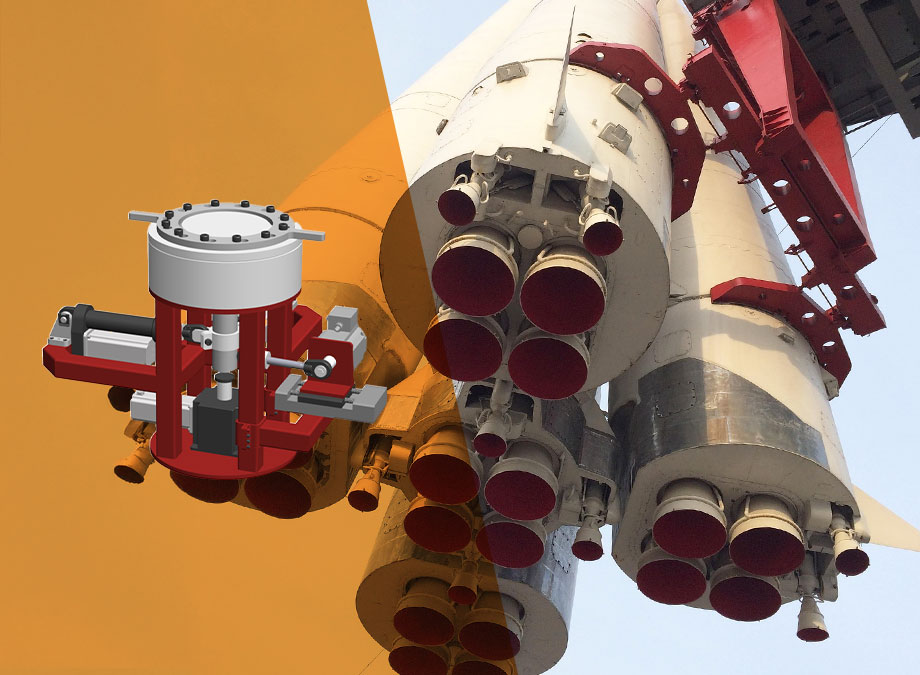

Test bench for a rocket propulsion component

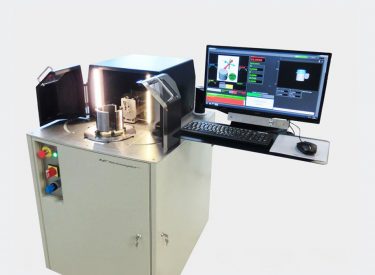

LF Technologies has designed a 100% electric test bench for rocket propulsion systems, combining complex motion generation, air/water pressurisation management and on-board data acquisition. A tailor-made, precise and ergonomic solution, designed to meet the requirements of the aerospace sector.

THE SOLUTION PROVIDED BYLF TECHNOLOGIES

Main functions

Design and manufacture of a customised test bench for rocket engines, incorporating a 100% electric solution for generating complex movements (tilting, oscillation, compression) and a controlled air/water pressurisation system. This test bench for rocket propulsion systems combines precision, repeatability and ergonomics to meet the requirements of the aerospace sector.

Issues

The tests involve generating complex movements (tilting, oscillation, compression), which must follow very precise position profiles and be perfectly synchronised.

Traditionally, these rocket engine test benches use hydraulic cylinders, a proven technology, but one that remains difficult to synchronise precisely in terms of position, particularly for complex and repeatable movements, as is the case here.

Our solution

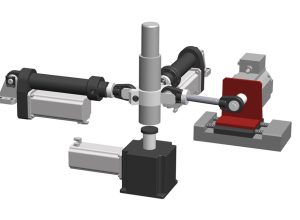

We have developed an innovative solution based on electric actuators, offering superior positioning accuracy, native synchronisation and precise control of movements.

In addition, the rocket propulsion test bench incorporates a pressure management system (air/water), on-board data acquisition, and complies with the safety requirements of the DESP directive.

LF Technologies has designed a customised test bench including:

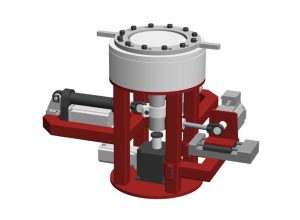

- A pressurised test chamber designed in accordance with DESP standards and a servo-controlled pressurisation circuit.

- Three synchronised electric servo actuators to generate tilting, oscillation and compression forces

- A control and acquisition system developed using LabVIEW

General operation

Secure mounting of the part

Thanks to a turning device, the operator can easily secure the part to be tested on their tools before inserting it into the test chamber.

The clamping is precise, with seals ensuring airtightness.

Insertion into the enclosure

The tooled part is inserted at an ergonomic height, the lid closes with an assisted closing system, and sensors automatically validate that it is properly closed before pressurisation.

Pressure management

Air/water filling, automatic purging, controlled pressurisation via HP/LP circuits. A high-precision sensor detects even the smallest leaks.

Generation of movements

- Tilting by two synchronised (servo-motorised) cylinders with inclinometer for automatic verification

- Compression by vertical cylinder with non-contact displacement measurement (laser)

- Tilt oscillation via mechanical eccentric ensuring optimal profile accuracy

Acquisition and supervision

The LabVIEW control software enables you to:

- Programming test sequences

- View live curves

- Save data and edit automatic reports

- Manage rights according to user levels

Result

Thanks to this new-generation test bench for rocket engines, aerospace manufacturers benefit from:

- A reliable and accurate 100% electric solution

- With an intuitive and scalable control interface

- With excellent repeatability and measurement accuracy

- A reduction in handling time thanks to ergonomic assembly

Products tested

Rocket thruster

A rocket engine is a motor that generates the thrust needed to launch and control a rocket by expelling gas at high speed.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

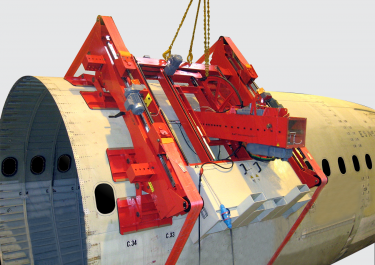

Other sector applications

Discover other test benches and special machines designed by LF Technologies.