Torsion bench for transmission and steering components

The torsion bench is a testing machine that subjects parts to controlled rotation in order to measure their torsional strength, torsional stiffness and hysteresis, while accurately recording the forces, deformations and behaviour up to failure if necessary.

THE SOLUTION PROVIDED BYLF TECHNOLOGIES

In the automotive industry, components subjected to rotational forces — shafts, cardan joints, couplings, steering columns, transmission joints — must maintain their torsional performance from the first kilometre to the last.

To ensure this, manufacturers check torsional strength, cyclic fatigue, elastic behaviour, stiffness coefficients and breaking point under conditions close to real-life conditions (temperature ranges, environments, cycle profiles), in accordance with standards and field practices.

An automotive equipment manufacturer approached LF Technologies to design a customised torsion test bench to qualify its critical components before they are integrated into vehicles.

Products tested

Elastic coupling/clutch/torque limiter/clamping ring

Transmission components transfer torque from the engine to the wheels (shafts, drive shafts, couplings, gearbox, differential). Steering components convert the movement of the steering wheel and steer the wheels (steering column, rack and pinion, tie rods, ball joints).

Expressed need

- Check the torsional strength (breakage) and cyclic fatigue (service life) of the transmission shafts or cardan joints.

- Measure the angular stiffness and deformation behaviour (torque/angle relationship) of couplings or flexible joints.

- Apply actual operating conditions (temperature variation, repetitive cycles, rotational speeds) to simulate the vehicle environment.

- Produce traceable reports for internal validations and quality audits.

Proposed solution – MBT torsion bench

LF Technologies provided a customised configuration of the MBT torsion bench, adapted to automotive constraints:

- Capacity up to 1,000 Nm and adjustable speed up to 400°/min on configurable cycles.

- Standard interchangeable chucks for adaptation to shaft or cardan shaft geometries.

- Dual preloaded transmission system to eliminate backlash, ensuring accurate and repeatable measurements.

- Automatic break detection and test termination in the event of breakage.

- Simultaneous measurement of angle (high-resolution encoder) and torque (strain gauge sensor), with integrated calculation of torsional stiffness and absorbed energy.

- Integrated thermal chamber option to simulate extreme conditions (e.g. high-temperature or cold operation during testing).

- Cycle control software, data acquisition, curve analysis, automatic report generation.

Results achieved

- Ergonomics and ease of use: parts can be set up quickly, adjustments are simple, and the control software is very intuitive. This allows users to start tests quickly, limit handling errors, and save time on a daily basis while remaining in a secure and reliable test environment.

- Reliable component validation: the customer was able to verify that its shafts and cardan joints comply with specifications for maximum stress, cyclic fatigue, and expected service life.

- Early detection of weak points: torsion tests identified areas of weakness (premature failure, excessive deformation) before integration into the vehicle.

- Automated test cycle & time savings: thanks to cycle programming and automatic shutdown in the event of breakage, the equipment manufacturer has reduced validation times compared to manual or less sophisticated tests.

- Traceability & reporting: each test is archived with graphs, raw data, certificates — can be used for quality audits or internal approvals.

- Realistic simulations: the temperature option allows parts to be tested under conditions similar to those found in the engine or transmission environment (heat, temperature variations).

Fabrice G.

Validation Engineer Automotive Equipment Manufacturer

With this torsion bench, we were able to validate our transmission systems across a full range of loads and temperatures. Automated reports enabled us to reduce validation time by 30% compared to previous solutions.

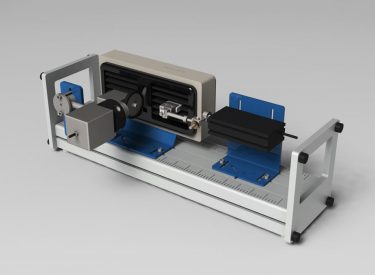

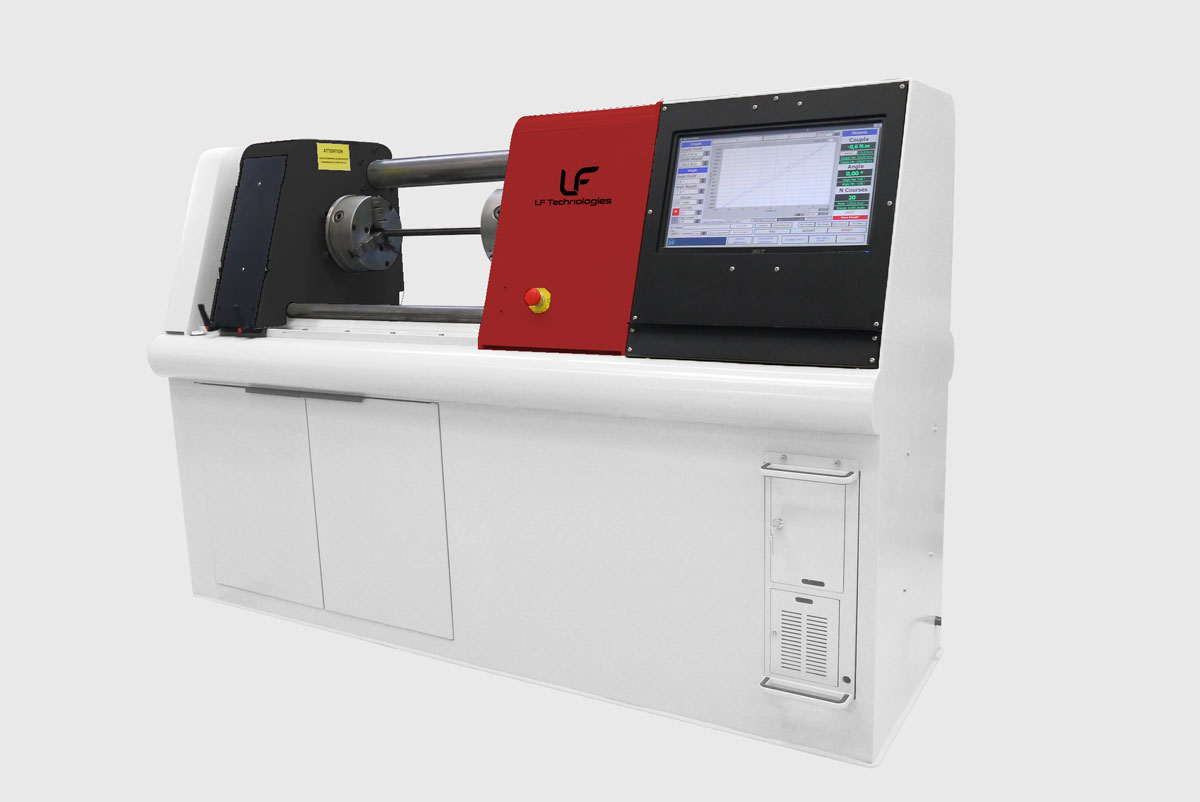

MBT – Torsion Bench – LF Technologies

Torsion Bench - Automotive R&D

MBT Torsion bench – LF Technologies

MBT Torsion bench - LF Technologies

Torsion Test Bench – MBT

Torsion Test Bench - LF Technologies - Automotive Sector

MBT Torsion bench – LF Technologies – Zoom

MBT Torsion testing machine - LF Technologies - Zoom

torsion bench in test area – LF Technologies

torsion bench in test area - LF Technologies

Our key equipment Torsion Bench – MBT

Principle and description

The torsion test bench performs programmable sequences until the parts break, with capacities of up to 1,000 Nm and 400°/min. It automatically calculates torsional stiffness and deformation energy. The test specimens are held on a movable/sliding headstock, allowing variable lengths of up to 500 mm. Torque measurement is based on a strain gauge sensor, while the angle of rotation is measured by a high-resolution encoder.

Operation

The product can be quickly set up using standard interchangeable mandrels. Tests are programmed in automatic cycles using simple parameters, while a backlash compensation device — with double pre-tensioned transmission — ensures zero backlash during operation. The measuring chain offers high angular resolution for accurate readings. Finally, the working length can be adjusted using a sliding head equipped with a brake, allowing the device to be adapted to different part geometries.

Bench developed to meet these standards:

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.