Leakage test bench for filters

Air leakage test bench for automotive filters. Contact us for your leakage measurement equipment requirements!

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is a global expert in filtration technology. It designs, develops and manufactures filtration and fluid control systems.

Main functions

Objective

The leak test bench is used to validate the conformity of the filter under test according to a defined test protocol.

PROBLEMATIC ISSUES

An air filter is designed to let air through while trapping impurities. To make sure that the filter is of good quality and that there are no holes, the test consists of pressurising the inside of the filter with a precise pressure and making sure that no air passes through (small leak).

The difficulty lies in detecting the leak. As a filter is “soft”, a flow measurement would not be revealing (the filter inflates under pressure).

By immersing the filter in water, you can check for the presence of bubbles when it is pressurised, and thus for any leaks. To detect bubbles, it is necessary to use a surface tensiometer, which detects disturbances on the surface of a fluid.

SOLUTION AND RESULT

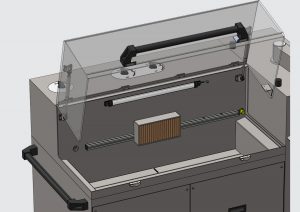

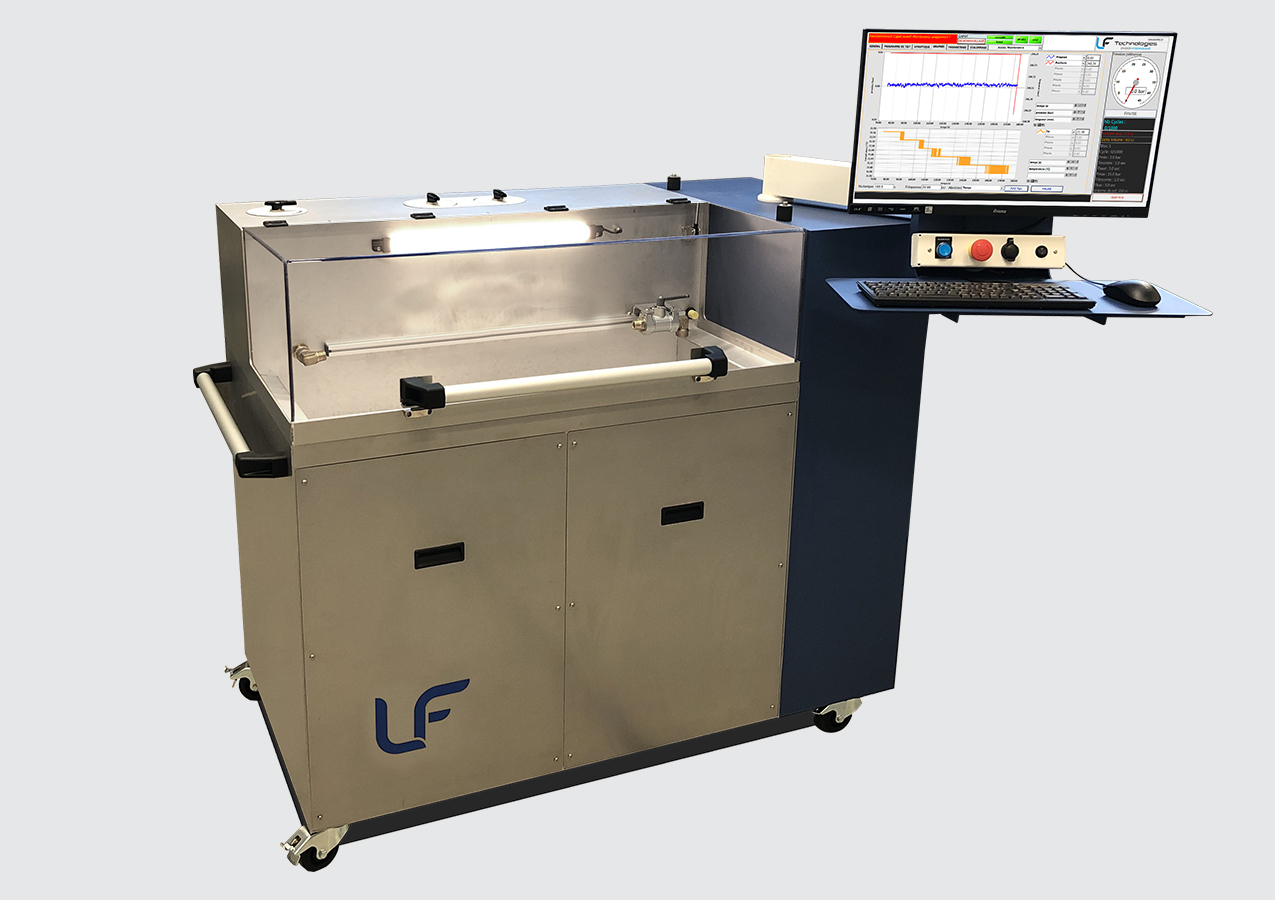

The equipment studied by our teams is an immersion air leakage test bench. The unit consists of a stainless steel frame topped by a polycarbonate tank.

A mirror is placed at the bottom of the tank to allow simultaneous observation of both sides of the filter under test.

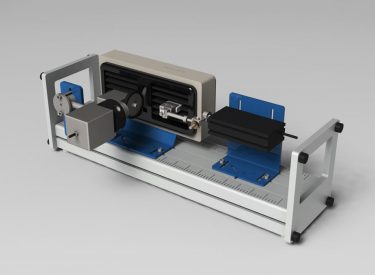

The part to be tested is fixed in the tank on a rotating support. This allows the filter to be turned without having to be dismantled. A level sensor mounted on the filter support measures the height of water above the filter.

The system is designed to operate with demineralised water.

Compressed air is supplied via the air network. A filter upstream of the circuit prevents impurities from entering the test air circuit. A pneumo-valve controlled by a pneumatic distributor opens and closes the pneumatic test circuit.

A temperature sensor monitors the water temperature. A level sensor measures the depth of the filter in the water.

Water tension is measured outside the tank using a tensiometer. The precision values measured are recorded on a PC. These measurements are used to check compliance with test conditions based on configurable criteria (e.g. temperature between 17 and 27°C).

Tested product

Automotive filters

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.