Horizontal compression tester 2,000 kN / tension 1,300 kN

The horizontal compression or tension machine measures the compressive/tensile strength of the dampers by applying a horizontal compressive/tensile force to a sample.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

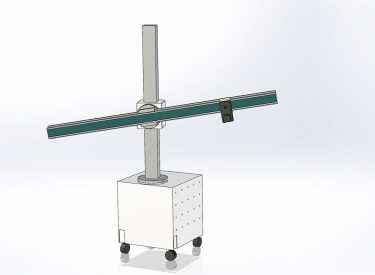

Our customer, a designer and manufacturer of shock absorbers, approached us with a requirement for a vertical bench to apply compressive or tensile forces at controllable speeds, positions and forces.

Main functions

Objective

Characterise the force/displacement curve of a shock absorber at low speed

PROBLEMATIC ISSUES

- Simple to operate and design

- Long stroke 3,000 mm

- High force Compression 2,000 kN / Traction 1,300 kN

- Risk of splashing elastomer or liquid contained in the tested products.

SOLUTION AND RESULT

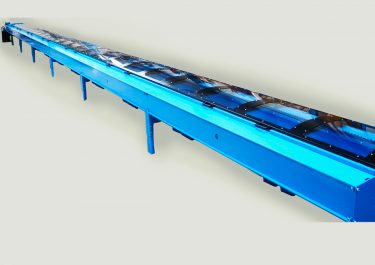

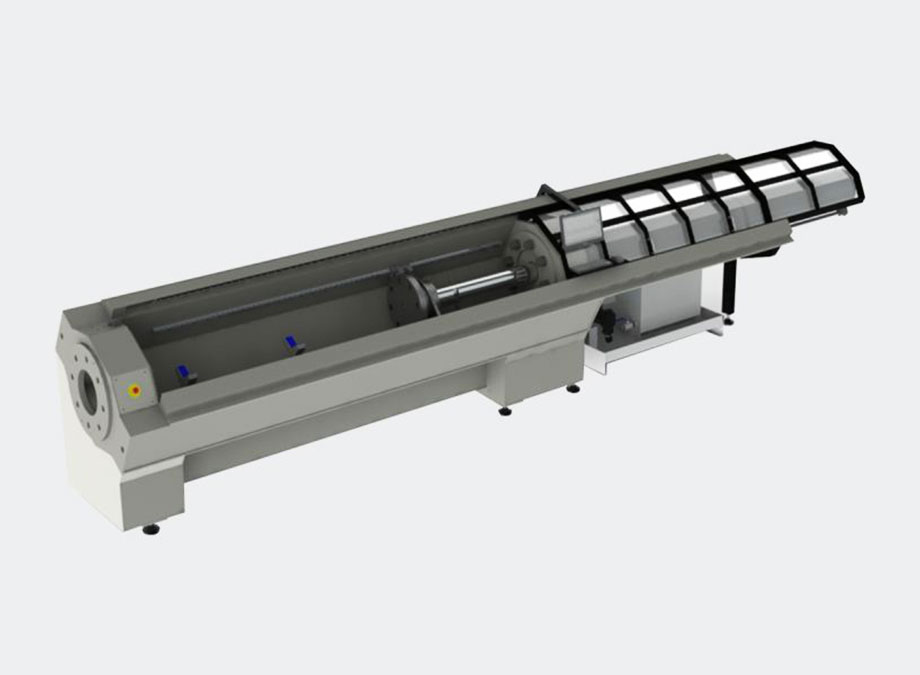

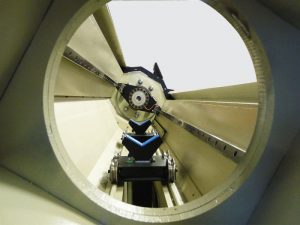

The horizontal machine has been designed to apply compressive or tensile forces with controllable speed, position and force to long-stroke railway shock absorbers.

A double-acting hydraulic cylinder is used to generate both a compressive force (rod extension) and a tensile force (rod retraction).

The useful hydraulic pressure is generated by a variable displacement pump, controlled by a load sensing system.

“Load sensing” system: a hydraulic system that automatically adjusts the inclination of a variable displacement pump’s plate based on the maximum required load (pressure). This system ensures that sufficient pressure is always available while optimizing the power consumed by the pump.

Two protective doors are structured to protect the operator in the event of possible projections of elastomer or liquid contained in the tested products.

Products tested

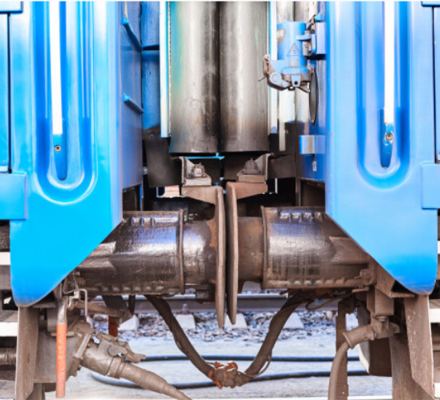

Shock absorber

This is a mechanical system that reduces the violence of an inertial shock. The shock energy is absorbed by the shock absorber, without rebound.

These shock absorbers are sized according to the speed and mass to be braked.

Tension and compression test area

Area di prova di tensione e compressione

Horizontal compression tester 2,000 kN / tension 1,300 kN

Banco prova di compressione orizzontale 2000 kN / Banco prova di trazione 1300 kN

Traction-compression bench

Panca a trazione-compressione

Horizontal traction bench

Banco di trazione orizzontale

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.