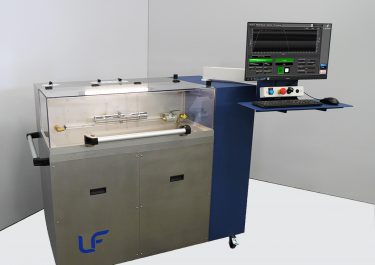

Thermal shock bench for pipes

A test bench that checks that the pipe is in good condition.

It ensures that there is no deterioration of the product.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

The CSTB is one of the historical customers of LF Technologies, which uses our test benches for many types of fittings and sanitary fittings.

The CSTB’s mission is to guarantee the quality and safety of buildings and to support innovation in the construction field.

This mission is accomplished through its activities: research and expertise, evaluation, certification and dissemination of knowledge.

Main functions

Objective

Check that the product is in good condition and that there is no deterioration of the product (leakage, breakage, etc), check if the pipe can resist to pressure and thermal shocks, for its entire lifetime.

This test has to be made according to standard as : EN 12293 Plastics piping systems. Thermoplastics pipes and fittings for hot and cold water. Test method for the resistance of mounted assemblies to tempetarure cycling.

PROBLEMATIC ISSUES

Ensuring a rapid temperature shock despite the large volume of the tested pipes.

Solution to the problem of energy saving due to the need to heat and cool the water after the temperature shock.

SOLUTION AND RESULT

The equipment is a loop that allows water to circulate in a pipe under a controlled dynamic pressure, at a controlled temperature, at a controlled flow rate that limits the temperature variation in the pipe under test.

The proposed equipment consists of three parts :

- The test zone includes the pipe to be tested, the lifting system and the air cooling system.

- The hydraulic cabinet, comprising the tanks, heat exchangers and hot and cold water pressurisation circuits.

- The pivoting electrical cabinet comprising the electrical board and the control panel.

To achieve thermal shock, the system calculates the optimum moment to switch the water diverter valves to the hot or cold circuit, which minimises the mixing of hot and cold water, thus saving a great deal of energy.

Upstream pressure is generated by a pressure-controlled centrifugal pump.

The flow rate is regulated by a proportional control valve downstream.

This flow rate is large enough to ensure a temperature loss of less than 5°C, and small enough to ensure uniform pressure in the pipe (± 0.5 bar).

Tested product

Food processing and hydraulic pipes + fittings

A pipeline is made up of pipes used to carry a fluid from point A to point B.

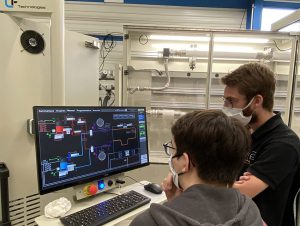

Electrical cabinet for the thermal shock bench for pipes

Electrical cabinet for the thermal shock bench for pipes

Thermal shock bench for pipes

Thermal shock bench for pipes

Thermal shock bench for pipes

Thermal shock bench for pipes

HYDRAULIC-PIPELINES

HYDRAULIC-PIPELINES

Set of tanks

Set of tanks

Ergonomic PC software;

Ergonomic PC software;

Thermal shock bench for pipes

Thermal shock bench for pipes

OUR KEY TEST BENCH FOR THESE TESTS Thermal shock and cyclic pressure bench for pipes THERMSHOCK

The torsion test rig can test samples up to 1,000 Nm and 400°/min, according to programmable cycles, until they break.

It automatically measures torsional stiffness and deformation energy.

The sample is attached to a sliding headstock, enabling testing of samples of variable lengths up to 500 mm.

- Easy product attachment thanks to interchangeable standard mandrels

- Program automatic cycles with simple parameters

- High angular resolution

- Adjustable length thanks to sliding headstock with brake

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.