Test bench for solenoid valves

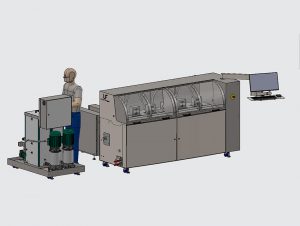

Performance and endurance test bench for electronic solenoid valve control. Thermal cycling tests on cartridges and their components are also possible with this bench.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Design and construction of an endurance test bench allowing the testing of 6 products simultaneously. The products are tested in accordance with the EN 15091 standard (Electronically controlled sanitary tap).

Problematic Issues

- Enable testing of multiple products simultaneously.

- Be able to generate alternating temperature stress cycles

- Generate water hammer

- Control electrical pulse times to within 0.1ms

- Measure high frequency pressure peaks.

Solution and Result

The equipment consists of a test bench with 6 modules and a pressure generator, designed to perform performance and endurance tests on the electronic part of the solenoid valve and thermal cycling tests on cartridges and their components. Each product under test is mounted in a specific tooling, allowing a choice of hot or cold water supply on either side of the supply. The bench is connected to a hot and a cold water inlet. The temperature and pressure generation is done outside the bench by an external module.

The 6 test modules are identical. A static pressure system is common to all 6 test lines.

Each test station is a module equipped with its own hydraulic circuit and an electronic control card, connected to the control PC by an Ethernet link. Each module allows to perform thermal stress tests, water hammer tests, to generate electrical control pulses of the tested product, to measure, at high frequency, the pressure peaks generated by the water hammer.

The software is capable of performing all performance, endurance and temperature cycling tests through simple programming.

Products tested

Electronic control of a solenoid valve (coil)

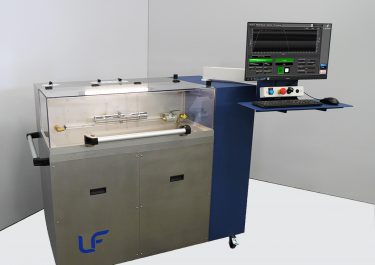

OUR KEY TEST BENCH FOR THESE TESTS LIFEEV solenoid valve endurance bench

LifeEV is an endurance test bench for estimating the service life, performance and hydraulic characteristics of solenoid valves for electronically opening and closing sanitary valves.

The tests are carried out to meet EN15091 standards.

Automatic test functions :

- Management of water supply solenoid valves (hot or cold on each supply)

- Automatic temperature cycling

- Solenoid valve open/close control with adjustable pulse duration

- Automatic search for the minimum electrical pulse duration to open the solenoid valve.

- Water hammer test on solenoid valve closure, with peak pressure measurement

- Static pressure test

Bench developed to meet these standards:

EN-15091

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.