Outdoor clothing waterproofness test

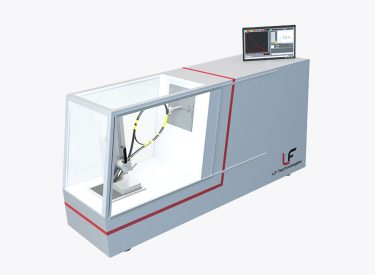

Development of a bench for demonstrating and testing the waterproofing of sailing equipment for the Tribord brand;

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is Tribord, the sailing equipment brand of the company Décathlon.

Main functions

Objective

Guaranteeing waterproofness – the waterproofness of outdoor clothing through rain simulation tests.

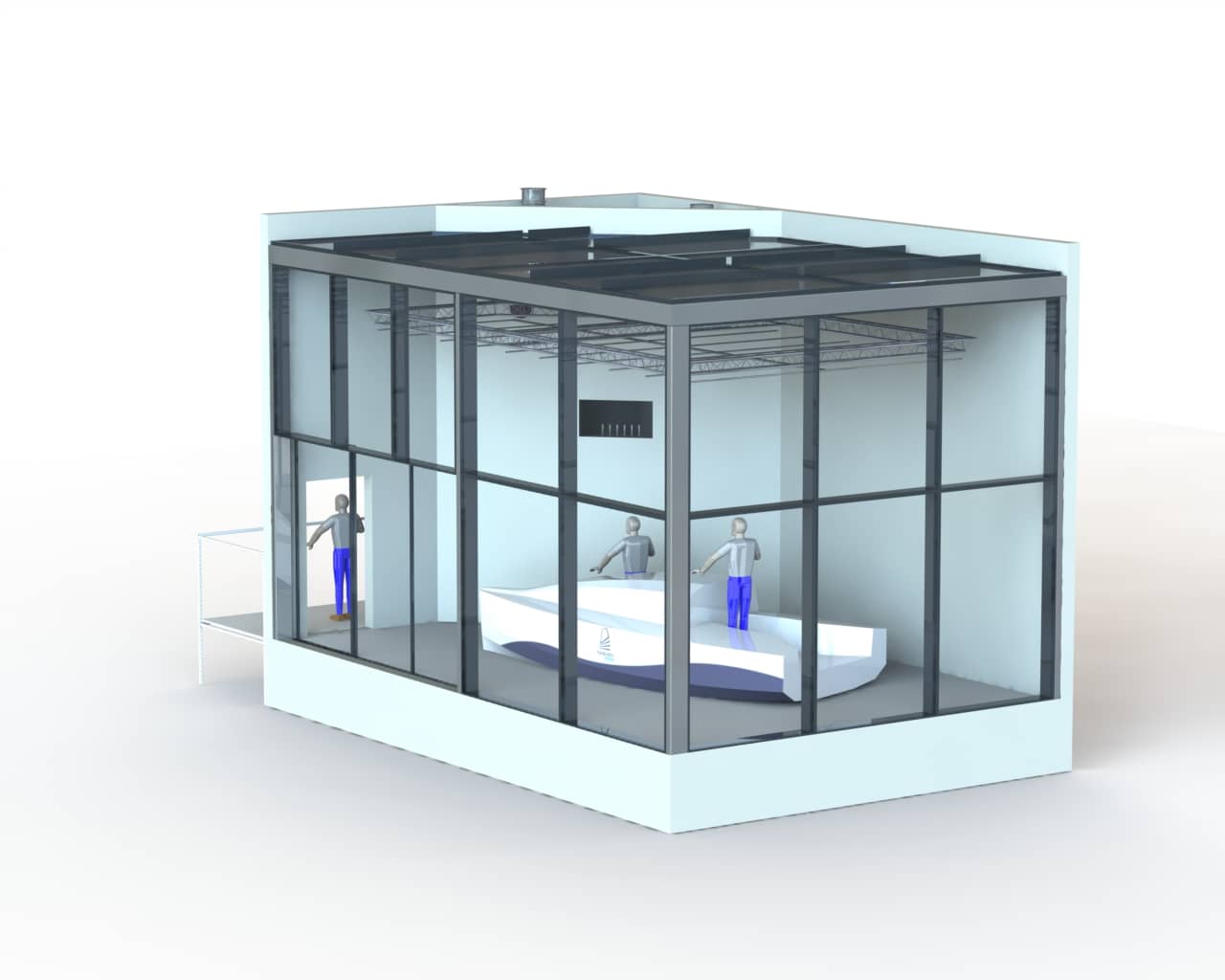

The demonstration bench called “Rain Room” is a room for performing waterproof tests on waterproof sail clothing by simulating rain by water projection. he room integrates a boat hull allowing reproduce real human maneuvering situations. This facilitates the detection of possible water infiltration in the clothing.

Problematic Issues

Our 7 major issues for the Rain Room

LF Technologies being in charge of the coordination and design of the demonstration bench enclosure, we worked in collaboration with Tribord and partner companies. Apart from the management of the different trades, our engineers had to face 7 major problems:

1 – Homogeneity of projections

To perform the rain simulation, we need a network of nozzles ensuring a homogeneous watering of the whole area.

2 – The water reserve

The basin must allow to have permanently a sufficient water reserve to supply the network that ensures the simulation of rain in the climatic enclosure

3 – A resistant floor

We need a grating (floor that lets water through) that is both solid, can be dismantled for access to the pool and has a high resistance to corrosion over time.

4 – Limit humidity

A ventilation system must be installed to limit humidity in the Rain room.

5 – Maintenance

The structure that supports nozzles and lights is located above the people in the enclosure. Its lifting system for maintenance must therefore correspond to the requirements of the Apave.

6 – Aesthetics and design

This bench is used as a test area but also as a showroom for Tribord. It is present in the new Decathlon research and development center in La Rochelle and is visible to the public. Tribord therefore attaches great importance to the aesthetic aspect of the structure.

7 – A structure that meets the standards

The steel structure has many manufacturing constraints In particular, the treatment of materials, compliance with earthquake‐resistant standards, adaptation to masonry, etc…

Solution and Result

Our solution, teamwork

By combining our know‐how and that of our partners, we have managed to find technical solutions for each problem encountered:

1 – We have carried out a large number of tests with different nozzles in order to obtain homogeneous results on the minimum and maximum flow rates for watering. We have chosen nozzles with a square impact perimeter, which simplifies the surface coverage and its homogeneity.

2 – We have equipped the enclosure with a 15 m³ pool and in order to preserve the quality of the water we have equipped it with a filter, a regulation system for chlorine as well as a skimmer at the entrance of the filtration system which allows to retain the elements on the surface.

3 – The grating is made of galvanized steel. It can be dismantled and placed on posts to facilitate access to the pool if necessary. This solution also ensures a more resistant and modular floor for future evolutions.

4 – For CMV, each duct is equipped with a sealed damper to block ventilation during the watering phases. The orientation of the grilles favours the circulation of fresh air and the evacuation of stale air.

5 – The steel structure is made of stainless steel to avoid premature deterioration of the framework in very humid environments. This solution meets all standards to ensure the safety of people inside the Rain Room.

6 – The test chamber is in the form of a canopy. This configuration imposes a special design that ensures optimal impermeability of the structure from the inside.

7 – We made an aluminium structure to hold the lights and nozzles; For maintenance purposes, the structure can be raised and lowered by means of a motorised winch that meets the requirements for hoists with people in them.

The future of the demonstration bench

We send the packet

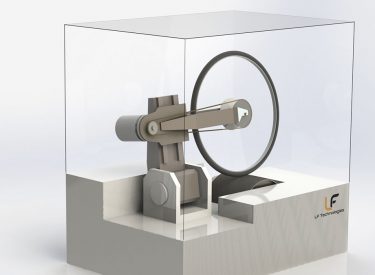

A sea wave module is currently being developed to simulate a wave hitting the hull of a boat, with the aim of optimising the accuracy of results during waterproofing tests on sailing garments.

It’s blowing here

Eventually, a wind simulator could be installed to vary the direction of impact of the drops on the brand’s waterproof clothing.

Products tested

Sailing clothing

The development of waterproof equipment at Tribord involves several months of research and rigorous testing. They have entrusted LF Technologies with the development of a test bench that enables them to test the waterproofness of their sailing clothing in the most extreme conditions.

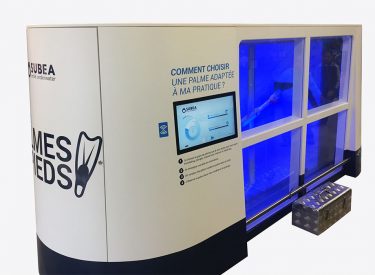

Waterproofing test on outdoor clothing Presentation of the demonstration bench

Presentation of the demonstration bench by France 3, during their visit to Tribord’s research and development centre in La Rochelle.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.