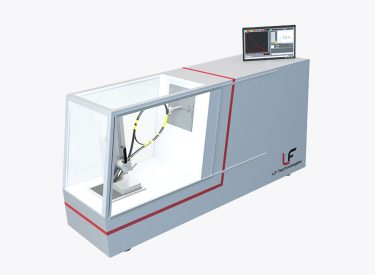

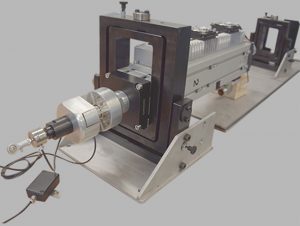

Ball Fatigue bench

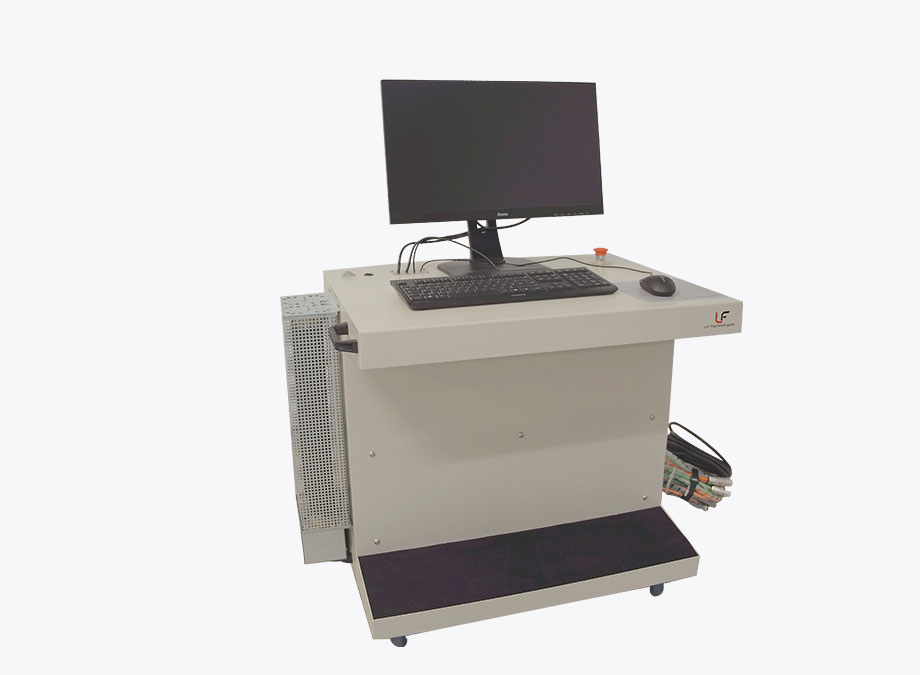

Cylinder control panel for fatigue testing of materials or products, once integrated into a fatigue device.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Carry out fatigue tests on composite materials, enabling the reproduction of mechanical stresses representative of real-life conditions.

PROBLEMATIC ISSUES

The fatigue testing device must be innovative and adapted to the materials to be tested. In addition, the system must be modular and scalable in order to integrate new functionalities according to the progress of the client’s research on the mechanical behaviour of composites, coupled with temperature and humidity.

The system must be able to be controlled according to complex position or force profiles.

Solution and result

LF Technologies offers a device comprising two electric cylinders, two force sensors and a control panel. Each axis is controlled independently, either manually or according to a programmed trajectory. In addition, each axis is equipped with a linear or brushless motor, controlled by a drive.

The integrated PC is equipped with a specific software that allows to visualize and control the measurements, actuators and drives (ON/OFF position, zero search, etc.), to perform the automatic cycling according to a programmed trajectory, to save the measurements made during a test and to calibrate the measurements. Manual or programmed motion is controlled via an analogue speed setpoint, and position is measured by an encoder feedback. Force measurement is provided by a tension/compression sensor.

The programming of complex position or force trajectories is done simply from spreadsheet files, which can be derived from measurements made in real conditions.

This control device can be used alone or integrated into a mechanical endurance test bench to test the fatigue life of a product or material. It is installed in the Research & Development laboratory.

TESTED PRODUCT

Composite materials

Actuator control for fatigue systems

Actuator control for fatigue systems

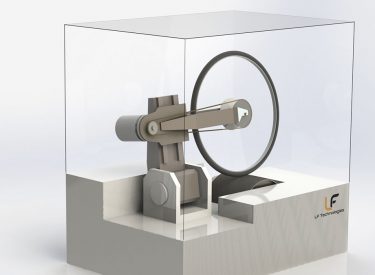

Bench-mounted linear actuator

Bench-mounted linear actuator

Linear actuator

Linear actuator

Fatigue bench for balls

Fatigue bench for balls

Carbon fibre tested

Carbon fibre tested

3d test analysis screen

3d test analysis screen

Tennis Ball Fatigue Test

Tennis Ball Fatigue Test

Linear actuator

Linear actuator

Tennis Ball Fatigue Test

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.