3 axis machining centre

The 3-axis machining centre made by LF Technologies automatically carries out the machining of holes and milling on aluminium profiles, such as door frames or sills.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is a large manufacturer of openings for the building industry.

Main functions

Objective

To carry out automatic machining of holes and milling on profiles (door frames and sills).

PROBLEMATIC ISSUES

To produce a 3-axis machining centre that is very simple to program and use, easily controlled by all types of operator, including non-machinists.

The machine must be designed to limit all idle times (tool change, workpiece clamping, etc.)

SOLUTION AND RESULT

The technical solution provided by the LF Technologies teams was to develop a machining centre consisting of several removable spindles, each with a different tool for machining, in order to drill holes of different diameters adapted to each profile, without changing tools.

The profile to be machined is placed manually on a removable support, equipped with a precise positioning device and an automatic locking system controlled by the operator. The machine is equipped with an optical sensor that automatically adjusts the machining programmes in relation to the end of the profile.

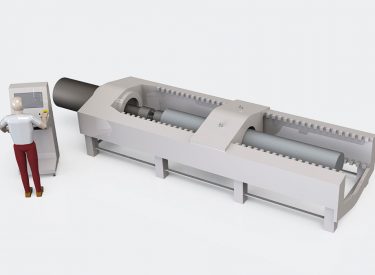

The machine is also equipped with a 3-axis numerical control (X, Y and Z) which performs 3 movements:

- The profile is attached to a carriage that moves on a double-rail support over a distance of 3 m. This movement is applied by a ball screw with a rotating nut (X axis);

- A fixed chassis, located at mid-length, houses a rigid frame with a vertical plane and horizontal movement. This frame slides on two precision linear guides and is driven by a horizontal axis ball screw (Z axis);

- Another frame with a vertical plane and vertical movement slides over the previous frame with horizontal movement. It is driven by two synchronised ball screws with a vertical axis (Y axis).

Depending on the application programmed by the operator, the electro-spindles machine the aluminium profile, with the option of X, Y and Z movements. The machining centre is equipped with 2 software programs that indicate the position of the tools in X, Y and Z, as well as allowing unlimited storage of different machining programs. This programming software is very easy to use and intuitive, as requested by the customer.

Tested product

DOOR THRESHOLD

The door frame is the frame of the door that is fixed to the wall to support the door leaf. A door sill is the bottom rail of the door frame, whose purpose is to protect the interior of a room from outside infiltration.

Working area

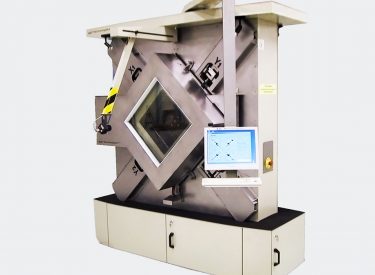

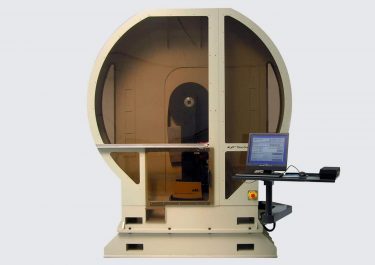

Working area

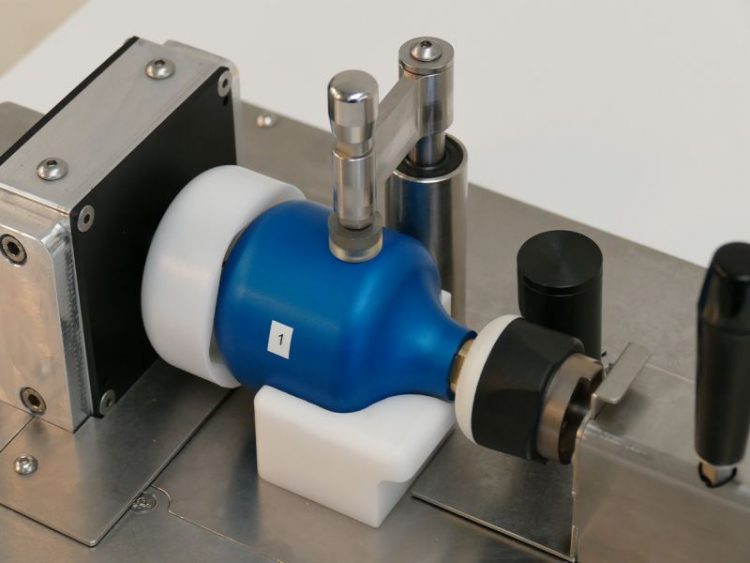

Profile on machine

Profile installed on 3-axis machining centre

DOOR SILL PROFILE

The door frame is the frame of the door that is fixed to the wall to support the door leaf. A door sill is the bottom rail of the door frame, designed to protect the inside of a room from outside infiltration.

3-axis machining centre

3-axis machining centre

OUR KEY TEST MODULE FOR THIS door sill machining centre Mo-A-brid

The clamping modules ensure that the parts are held in position on the machine. Our clamping modules are custom-designed according to your application specifications.

Choice of clamping technology adapted to the specificities of each application.

- Pneumatic control

- Hydraulic control

- Electrical control

Bench developed to meet these standards:

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.