Why test a faucet on a test bench ?

There are various reasons why manufacturers decide to test a sanitary faucet: specifications, compliance obligations, factory production quality requirements, etc. We explain why each step is important and what it involves.

SOMMAIRE

Compliance with faucet standards and certifications

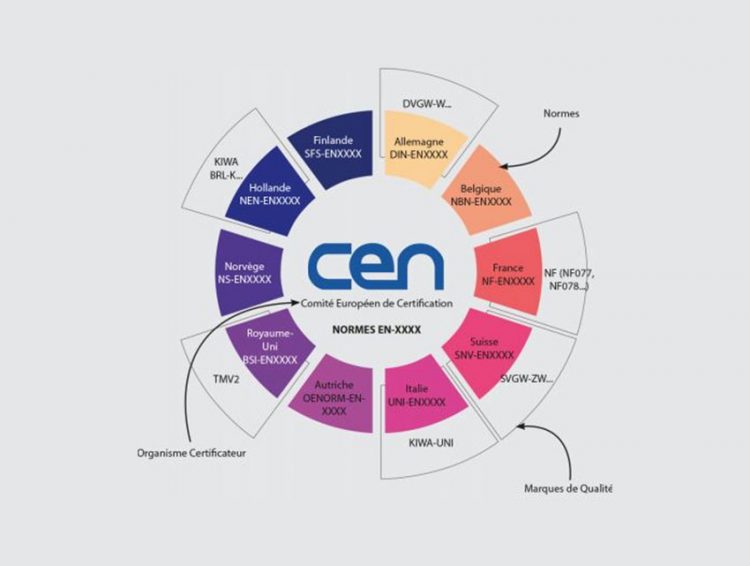

In order to provide consumers with as much safety as possible in the use of their faucets, numerous standards and certifications have been put in place. These impose technical and environmental constraints that allow for an effective fight against the overconsumption of water, energy and pollution. The standards also ensure the consistency of the essential characteristics of products, including quality, economy, reliability, compatibility, interoperability and efficiency. These rules have been established through close collaboration with installers and customers, with the technical centers of the mechanical and building industries, and with various European valve research laboratories.

Access to certain markets

Each country has its own standards and certifications for faucets. Depending on the regulations in force, it is possible that if a valve does not pass certain tests, it cannot access certain markets. In France, for example, we have the NF certification, without which manufacturers cannot access the low-cost housing market.

In terms of product safety, in a market for health establishments, there is the NF 077 MM certification, which requires, among other things, taps that avoid any stagnation of water and that offer the possibility of blocking the temperature.

Marketing argument to consumers

A faucet that has been tested and approved by several standards will be a guarantee of confidence for consumers. This can therefore be a significant marketing advantage for manufacturers. Customers prefer to invest in quality equipment rather than pay for water damage repairs.

Comfort and design are also elements that a manufacturer will emphasize, especially for bathroom faucets.

Research & Development

Testing faucets during the research and development phase will both test new products and make improvements to existing ones.

Some manufacturers even go beyond the demands of certification bodies to ensure the robustness of their faucets and stay ahead of the competition.

Respect of the specifications

The design office will establish the functionalities, settings and constraints that the valve must meet. In order to verify that the prototype meets the expectations of the specifications, the manufacturer will put the valve on a test bench.

Valve quality

Quality tests can be used to test a valve before, during and after production. They will be used in several cases:

- They allow to check the manufacturing process and make sure that there is no malfunction or drift on the production line.

- They help to avoid product recalls, by helping to identify possible tap defects or inconsistencies in the quality of a batch.

- Satisfy certification institutions that require regular product testing.

It also allows to perform conformity tests on the production. There are 2 ways of doing this:

- The test by sampling: we will recover a random sample and make it pass the tests.

- The unit test: all the production will be tested, but only for basic tests, such as temperature adjustment, tightness, anti-scald, etc.

Do you have a project ? Contact our test bench experts

Tightness and pressure resistance of the valve

The tightness test is an essential test to ensure that the valve is not damaged by high pressure. Manufacturers are very vigilant on this point, because a leak could generate important water damages or excessive water consumption.

They will also check that the sanitary faucet is resistant to water hammer that could occur in the water system.

User safety

Products such as thermostatic mixing valves have thermostatic cartridges. These cartridges have safety functions to prevent the risk of scalding:

- Limitation of the maximum temperature to 50°C

- The anti-scald limitation which ensures that the cartridge cuts off the flow of hot water when the cold water fails

Comfort of use

The comfort of use of the faucets will be measured according to several criteria:

- The ergonomics of the faucet: ergonomics of the handle and spout, ease of adjustment.

- A water saving system: limited flow mode

- An energy saving system: for mechanical and electronic mixers (an opening mode on cold water), for thermostatic mixers (a temperature control mode + a temperature limitation mode at 50°C)

In the case of a thermostatic valve, we will check, for example, that the thermostatic cartridge is doing its job properly. It is the cartridge that regulates the temperature, it will control the mixture of hot and cold water by itself, which will allow to obtain a stable temperature.

In order to best respond to your problems of R&D tests, quality and compliance with standards and certifications, it is essential for you to acquire a tap test bench. Indeed, it will allow you to make your tests in factory and it will be for you the insurance to validate your products even before the sending to a laboratory of certification, organization of type CSTB.

As a private individual, to know if a faucet corresponds to one or more standards and certifications, you can find them on the product’s technical sheet.

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test benchusers?

What are the most important tests on sanitary hoses ?