What are the main test points for a sanitary fitting?

In order to check that a mixer tap meets the quality requirements of the standards and certifications in force in the sanitary fittings sector, it is subjected to a series of tests. The different test points for sanitary fittings presented below are the most common.

SOMMAIRE

Leakage test

The purpose of the leakage test is to identify leaks in a faucet. These tests are performed upstream and downstream of the shut-off valve of a sanitary faucet. The obturator is the element that cuts off the water flow inside the tap.

To carry out the upstream test, the shutter must be closed and static water pressure is applied to the tap supplies.

For the downstream test, the valve must be open, static water pressure must be applied to the valve supplies and the valve outlet must be plugged.

Leak tests can be carried out in cold water.

To validate the test and comply with standards and certifications, there must be no leakage from the valve.

For example, to pass the EN test, the valve must withstand a pressure upstream of 16 bar and 4 bar downstream.

Pressure resistance test

This test is used to check the mechanical strength of the valve body under the effect of water pressure.

As with the leakage test, the resistance tests are carried out upstream and downstream of the mixing valve.

In order to validate this test, no mechanical deformation of the valve body should be observed. Any water leakage that may occur as a result of the test is not taken into account for validation.

For example, to pass the EN test, the valve must withstand a pressure of around 25 bar upstream and 4 bar downstream.

Hydraulic Performance Test

In order to test the hydraulic performance of a valve, several criteria are evaluated:

- Flow characteristics are measured as a function of water pressure and temperature setting.

- Sensitivity (smoothness of control) and accuracy (precision) of mixed temperature control are measured.

For self-closing valves :

- The volumes of water delivered by the valve are measured.

- The flow opening delay times are measured

For thermostatic mixing valves, several additional criteria will be evaluated:

- The precision of the temperature setting.

- Consistency of the mixed temperature in relation to variations in flow rate, supply pressure and supply temperature.

- The anti-scald safety, also known as anti-scald, makes it possible to check that there is no risk of burning for the user when the cold water supply is cut off. Indeed, when the cold water supply is cut off, the hot water flow must stop instantly. In an article, the CSTB explains why anti-scald has become a priority for sanitary fittings certification bodies

Do you have a project ? Contact our test bench experts

Mechanical resistance test

Mechanical resistance means checking that the handles do not break if you squeeze them too hard or that the diverter does not break if you pull on it too hard. To test the mechanical strength, a force or torque is applied to the operating devices.

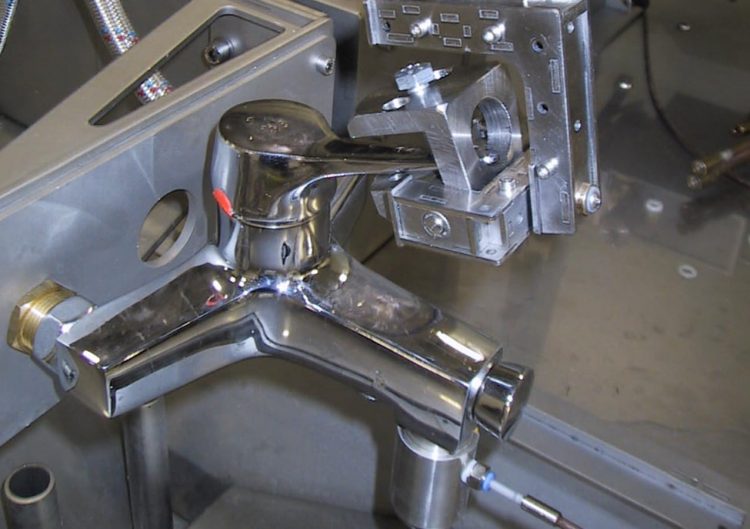

Mechanical endurance test

When talking about mechanical endurance, we check, for example, that the handles of the mixing valve do not break after only a few uses.

The purpose of the mechanical endurance test is to make all the moving parts (handles, diverter, etc.) perform a large number of cycles in order to check the reliability of the valve against wear. Depending on the test, the test can be performed with or without water supply.

At the end of the endurance test, the tests carried out previously can be repeated. This will ensure that the quality of the tap is still consistent after a long period of use.

Water hammer test

This test verifies the ability of the valve to shut off the flow without creating excess pressure in the water supply lines, known as the water hammer phenomenon. These tests are usually carried out on self-closing valves (timed valves or electronic valves).

To carry out the test, a long length of pipe is simulated by supplying a large quantity of water to the tap. After a quick closure of the mixer tap, the pressure peak generated by the sudden variation of the water speed in the network is analysed.

Alternating pressure test

When a tap is installed in a plumbing system, it is subject to significant pressure variations due to the opening and closing of other devices installed in the network (water hammer generated by the other equipment).

This pressure alternation must be abrupt and rapid (0.1 second).

This test is carried out at room temperature. No bursts or leaks should be observed before a very large number of cycles.

Here we have presented the main test points of a sanitary valve, but there are others such as acoustic, chemical and hygienic characteristics, etc.

If you would like more information about test points, standards and certifications. We can help you, so don’t hesitate to contact us.

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test benchusers?

What are the most important tests on sanitary hoses ?