How do you supply water to your faucet test bench?

There are several methods for supplying water to your faucet test stand. The method you use will depend on the types of tests you have to perform. You will need to determine:

- Your hot and cold water requirements for the tests: most endurance tests require only cold water, while performance tests require both hot and cold water. Some tests require variable temperatures, others require constant temperatures.

- The flow rate you need and the number of stations that will need to be supplied

- The pressure needed to perform the tests, whether it is constant or variable and whether it should be lower than your network pressure

- If you want a closed loop in order to save water

We will present you here different ways to supply water to your test bench. Do not hesitate to contact us for more information or to guide you towards the solution best adapted to your needs. Case 4: You have no water supply or primary loop.

SOMMAIRE

Case 1 : You already have a cold water supply but no hot water supply.

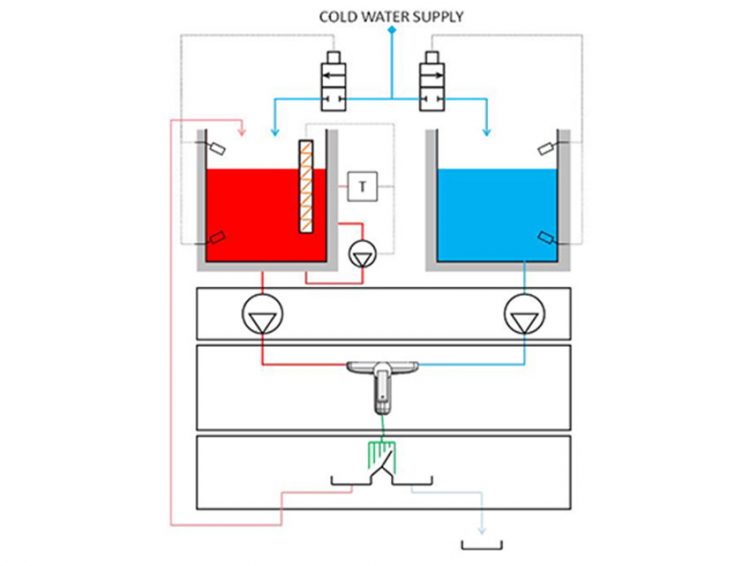

If you do not have a hot water supply, the simplest way is to install 2 tanks: 1 on the hot water supply of the bench (50 L) and one on the cold water supply (15 L) We add to that a heating system in the hot water tank and a distributor in the test bench. The distributor will draw a part of the mixed water to the hot water tank, which allows to create a closed hot water circuit (more economical in energy and water).

The other part of the mixed water is drawn towards the drain. In effect, the loop is open to cold water, so the total water consumption is equal to the cold water flow, but there is no need for cooling, because the cold supply is directly at your water supply temperature. This system is the simplest, as there is no cooling system. The disadvantage is that the cold water temperature is not adjustable.

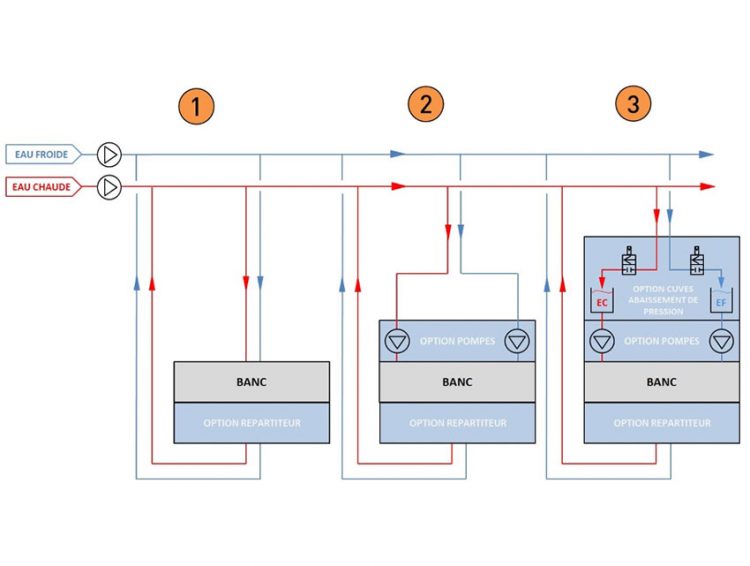

Case 2: You are working with waste water. You already have a hot and cold water production with sufficient heating and cooling power and a controlled temperature.

1 : The regulation of the pressure of your production is good (pressure of your production = test pressure) : In this case, you can feed the bench directly with your water production.

2 : You need to make pressure variations : you have to add pumps at the entrance of the bench on hot and cold water which will allow to make pressure variations beyond the network pressure. In this configuration the water pressure can only be increased.

3: You need to perform tests at a pressure lower than your supply pressure: you must first lower the pressure thanks to buffer tanks on the hot and cold water, then raise it in a controlled way thanks to the pumps towards the bench.

If you wish to have separate hot and cold water returns, you must install a distributor at the mixed outlet of the bench, to distribute the mixed water on the hot and cold return networks.

Do you have a project ? Contact our test bench experts

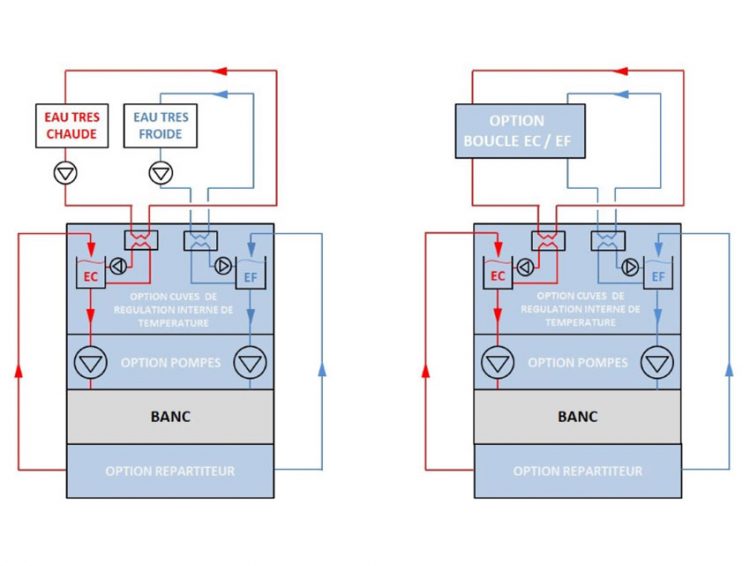

Case 3 : You have a primary circuit of superheated water and chilled water.

Your hot and cold water loop is used as an external source of heating and cooling of the bench. Water from the bench’s internal hot water tank is heated by a heat exchanger (with the hot water loop as the heating source). The cold water from the bench’s internal cold water tank is cooled by a heat exchanger (with the cold water loop as cooling source). There is no water consumption through the loop.

The heat exchanger systems allow for very good temperature accuracy (± 0.5°C on hot and cold) and you can easily change the hot and cold temperature setpoints.

Advantages :

- You can easily manage temperature and pressure with internal tanks and pumps.

- The test water stays in the bench (it does not communicate with your heating and cooling system), which allows frequent renewal.

- Very good regulation of the bench supply temperature and quick change of the hot and cold water temperatures

Case 4: You have no supply or primary water loop.

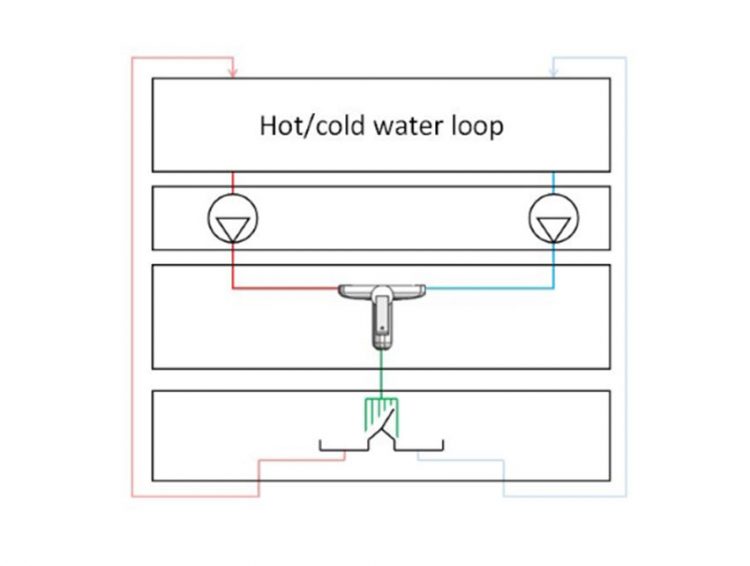

Solution 1:

The first solution is a small generator which feeds directly the bench. It consists of 2 tanks (hot and cold water) and has a heating system for the hot water tank of 20 kW and a cooling system for the cold water tank of 20 kW as well. The bench is equipped with a hot/cold divider so that the mixed water is drawn to the hot water tank and the cold water tank in a closed circuit, which avoids water consumption. There is an energy saving on hot water, but the system needs energy to cool the cold water. There is no heat recovery from cold to hot.

The accuracy of the hot tank is ± 1°C and the cold tank is only ± 2°C. This will be sufficient for most endurance tests, but not for some performance testing.

Solution 2:

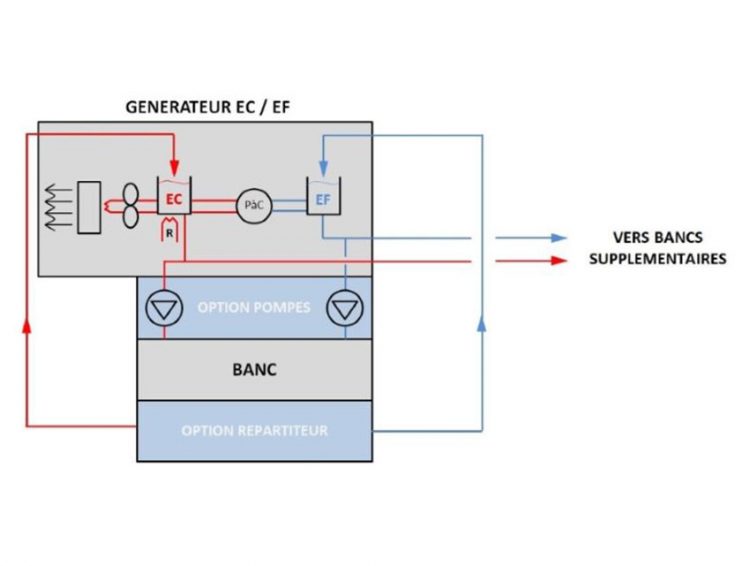

The bench is powered by a more powerful hot and cold water generator than in solution 1. The generator ensures the temperature control of a hot water reserve and a cold water reserve. The bench pumps hot and cold water directly into these reserves.

This system makes it possible to supply one or more tap test benches (depending on the flow rates of each bench). The system works in a closed water circuit. It has a large thermal power (30 kW for hot water and 30 kW for cold water) which allows to ensure a continuous flow of hot/cold water mixture. Thanks to the large capacity of its internal tanks (400 L for hot water and 200 L for cold water) the generator can provide a very large instantaneous flow. This configuration is able to supply benches with a very high temperature accuracy (± 0.5°C in hot and cold), whatever the hot and cold water flow rates (within the maximum flow rates). The heat pump ensures cooling and saves energy, because part of the calories from the cold production is recovered to heat the hot water. The excess heat is evacuated by means of a unit heater. This type of installation is often used for laboratories with several test benches.

Both solutions are similar, but solution 1 will be much cheaper with less temperature accuracy and less heating and cooling power. Unlike solution 2, it does not have heat recovery from cold to hot. You can find more information about the differences between the 2 generators here: peripheral equipment.

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test benchusers?

What are the most important tests on sanitary hoses ?