Hydraulic test benches

Valves - static and cyclic pressure

Technical description

Main functions

This valve test rig is designed to test the tightness and pressure resistance of valves and valve accessories (hoses).

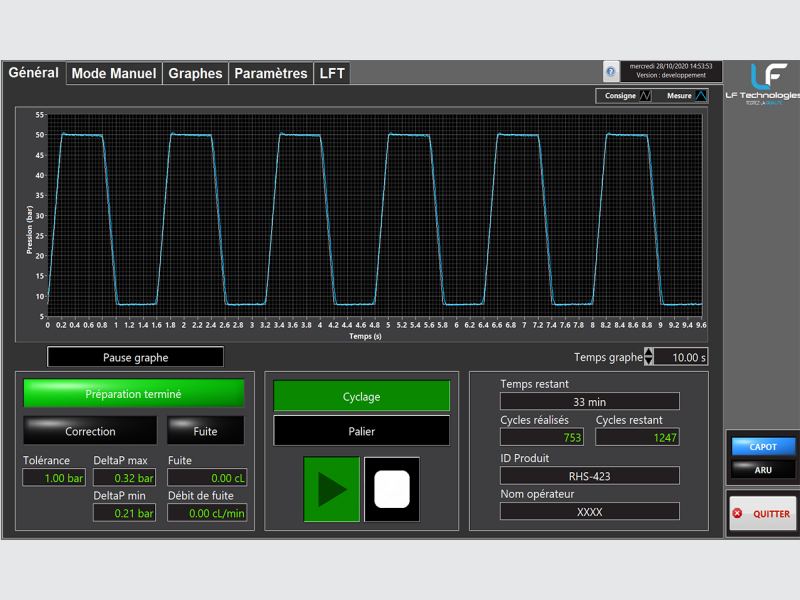

The bench can perform static pressure tests, up to bursting and alternating pressure tests to simulate water hammer.

Operating mode

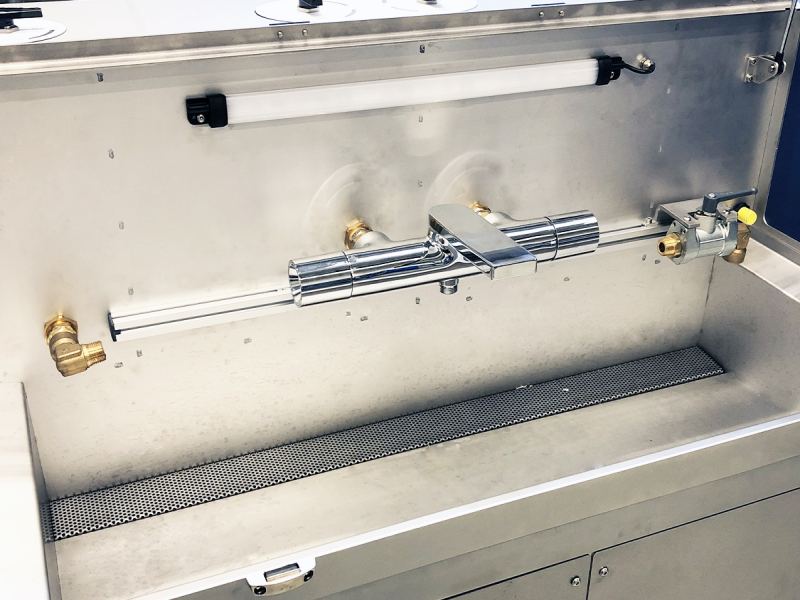

The product under test is connected to the tapping points on the front panel. Manual valves allow the product to be fed or vented.

The bench is equipped with a pressure system using a motorised plunger piston which compresses the water in the circuit. The displacement of the pressure generator piston gives a volume measurement. A sudden change in this volume measurement allows the detection of a leak or a burst.

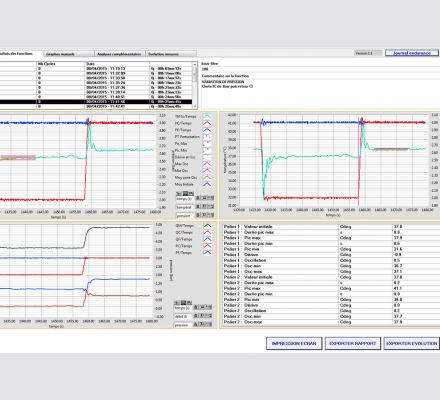

The system is equipped with a self-learning system that ensures automatic adjustment of the pressure cycle parameters, which optimises the pressure cycle shape without any user intervention.

The test area is equipped with a transparent cover with a safety switch that cuts off (or prevents) the pressurisation if the cover is not closed.

Characteristics of the device

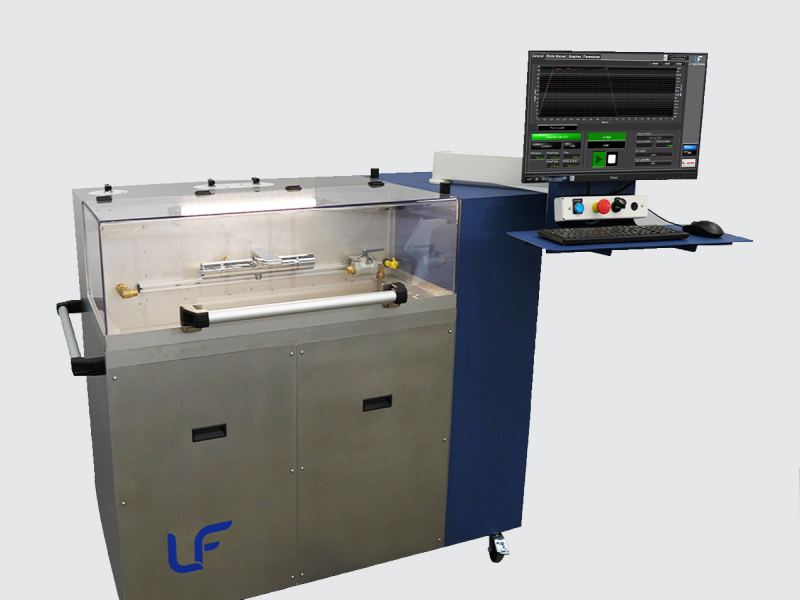

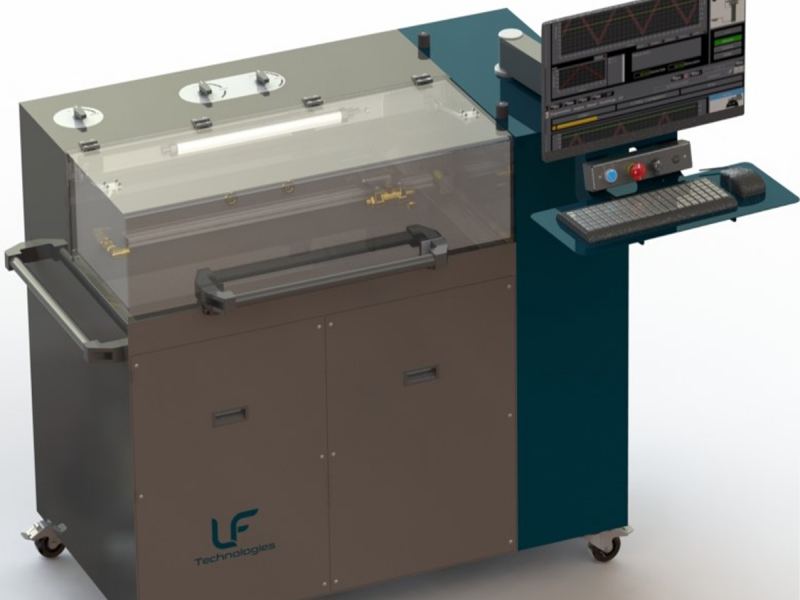

The test bench consists of 6 parts:

- The self-supporting stainless steel chassis on castors

- The test area, including the connections for the products to be tested and a recovery sink

- A transparent cover with closure detection system

- The hydraulic circuit including the pressurization system

- The electrical cabinet

- Mobile control panel including screen, keyboard and mouse

Pressure generator |

HydroShock-50 | HydroShock-100 | HydroShock-200 |

Maximum static pressure |

50 bar | 100 bar | 200 bar |

Pressure control accuracy (static) |

1 bar | 1 bar | 2 bar |

Pressure measurement accuracy |

0,5 % | 0,5 % | 0,5 % |

Maximum expansion volume |

40 cm3 | 40 cm3 | 20 cm3 |

Maximum cycling pressure |

30 bar | 50 bar | 100 bar |

Maximum frequency |

1 Hz | 1 Hz | 0,5 Hz |

Horizontal frame dimensions |

HydroShock-50 | HydroShock-100 | HydroShock-200 |

Length (mm) |

1 300 | 1 300 | 1 300 |

Depth (mm) |

700 | 700 | 700 |

Height (mm) |

1 150 | 1 150 | 1 150 |

Benefits

- Standard tests according to standards (Example NF077-doc tech 3)

- Programmable pressure cycle form

- Easy and quick installation of valves and fittings of any shape

- Automatic stop in case of leakage of the tested product

- Reproducibility of tests

- Automatic test analysis and reporting

- Compact package