Hydraulic test benches

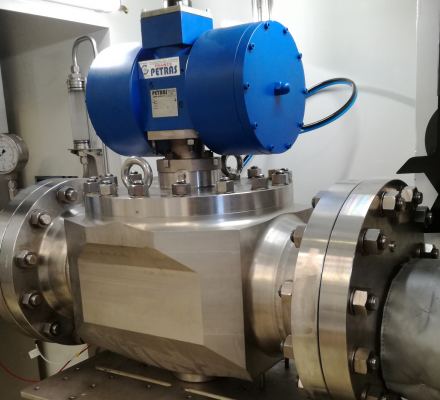

Taps

Reference

: LifeMulti

Areas of application

:

Technical description

Main functions

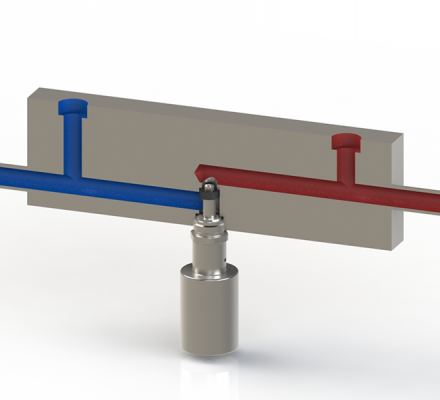

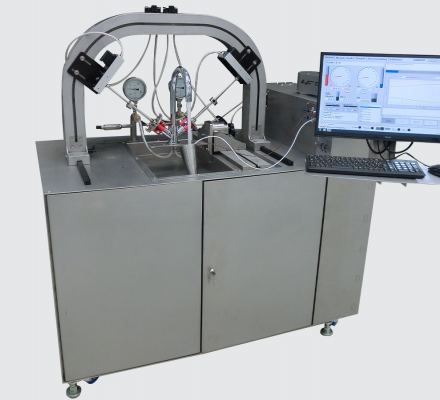

The endurance test bench is a test bench designed to test the lifetime of faucets, mixers, diverters, mechanical and thermostatic mixers in a fully automated way and according to NF, EN, ASSE standards, etc.

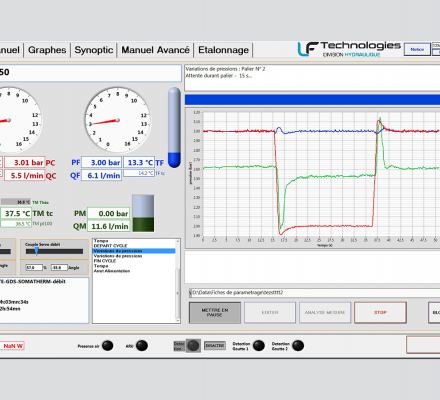

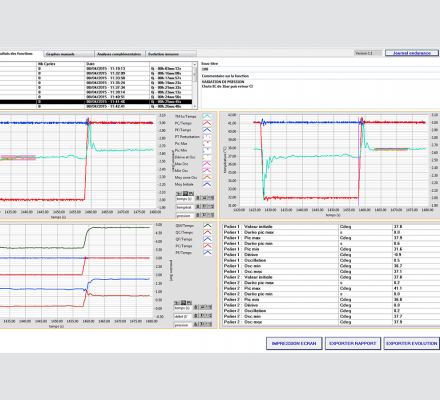

The machine is equipped with an automated measurement system evaluating the reliability of the valve during its endurance according to the evolution of the operating torque and its sealing.

Operating mode

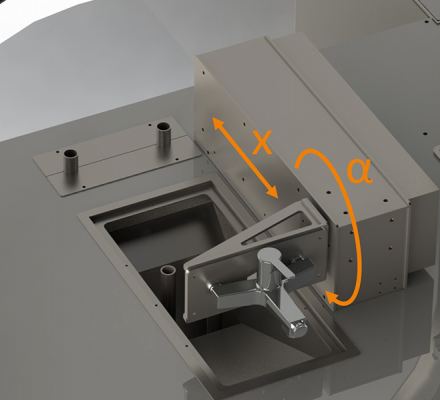

- Fixation of the faucet to be tested on the central stage;

- Adjustment of the faucet position;

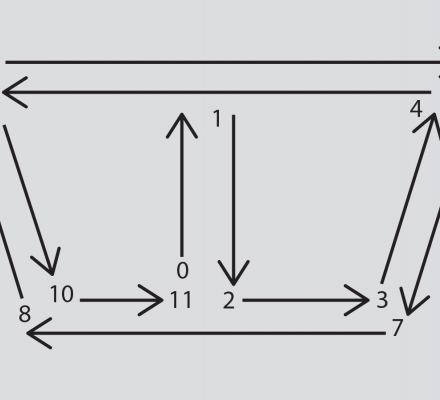

- Mounting of actuators for motion control (rotation or translation);

- Programming of tests on the control screen;

- Launch of scenarios.

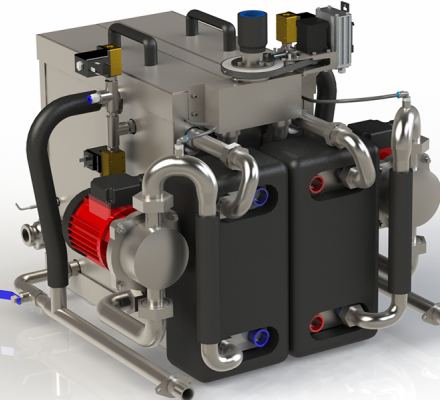

Characteristics of the device

- Stainless steel frame

- PC control

- Pressure control 0.1 to 6 bar ± 0.05 bar

- Flow rate 2x25 l/min

- Automatic leak detection

- Operation force/torque 100 N; 6 Nm

- Closed enclosure for protection against water splashes

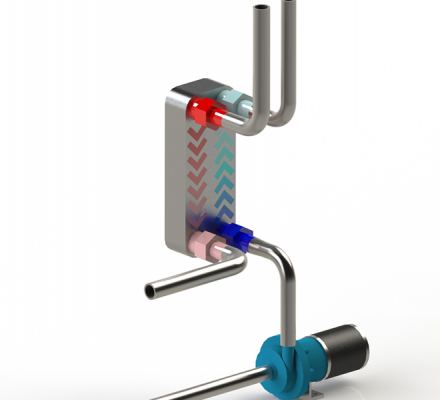

HW and CW flow rate

0-25 l/min

HW and CW pressure

0-6 bar

Pressure measurement

± 0,01 bar

HW, CW, MW flowmetry

± 0,1 l/min

Temperature range (depending on the source)

5-75° C

HW, CW, MW temperature measurement

± 0,2° C

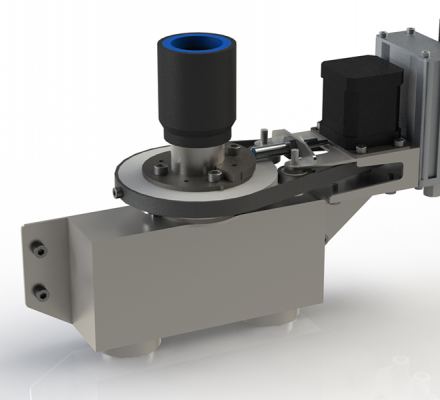

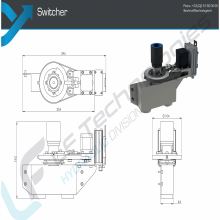

Rotary actuator

Max. torque in both directions

6 N.m

Max. speed in both directions

180°/s

Torque measurement resolution

0,01 N.m

Resolution of the angular position measurement

0,1°

Max. rotation angle

unlimited

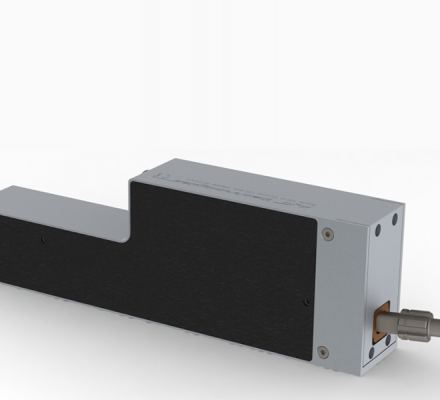

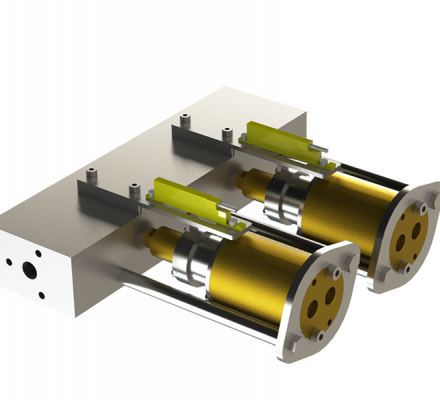

Linear actuator

Max. force in both directions

100 N

Max. stroke

125 mm

Max. speed

40 mm/s

Accuracy of force measurement

± 0,1 N

Accuracy of position measurement

± 0,02 mm

Width

550 mm

Depth

650 mm

Height

2 100 mm

Weight

» 170 kg

Advantages

- Quick and easy installation of faucets of any form

- Automatic tests without manual intervention

- Automatic termination in case of leakage or abnormal operating torque

- Reproducibility of tests

- Tests according to standards

- Automatic test analyses and reports

- Compact Equipment