Customer

Our customer is one of the world's leading players in the manufacture and design of pumps for water management, industry and construction.

Tested product

The customer wanted to be able to test the endurance of its 3-way valves and EC motors.

The motorised 3-way valves have 2 inlets and 1 outlet. They allow the regulation of a mixture of water with a constant flow at the outlet.

The EC motor is a pump coupled to an Electro-Commutator (EC) synchronous motor with a maximum flow rate of 0 to 3m³/h.

Objective

The purpose of this test bench is to carry out various types of endurance tests on T-valves and engines while collecting information on operation. The high temperatures of the water flowing through the system and the ambient air must cause premature ageing of the parts.

Problematic issues

The test bench must be able to perform different test conditions on a large number of samples simultaneously in order to achieve better failure detection.

A thermal environment in water and air must be created that reproduces the operating conditions.

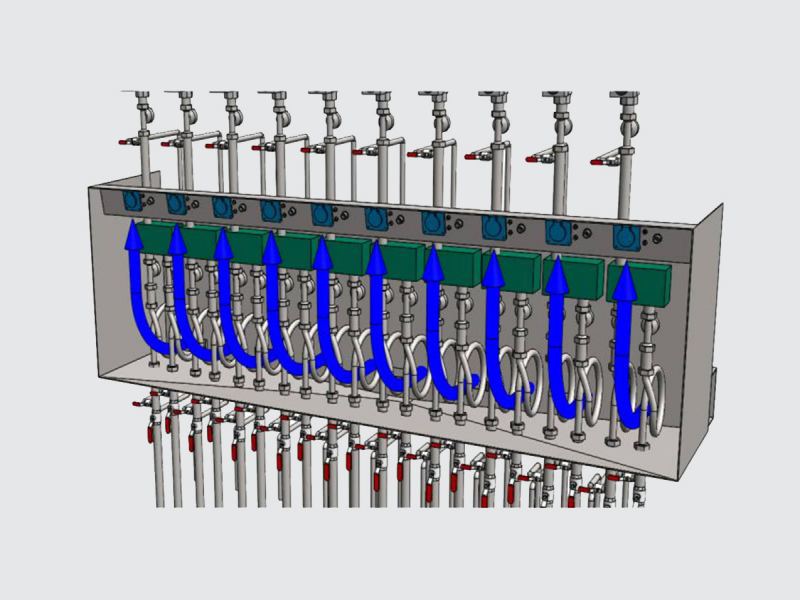

To test the endurance of 3-way valves, the valve must be opened and closed cyclically with regular to-and-fro movements.

To test the endurance of the EC motor it is necessary to carry out :

- Control tests with speed variations.

- Cyclic on/off power tests.

- Power supply tests with the motor running continuously.

Solution and result

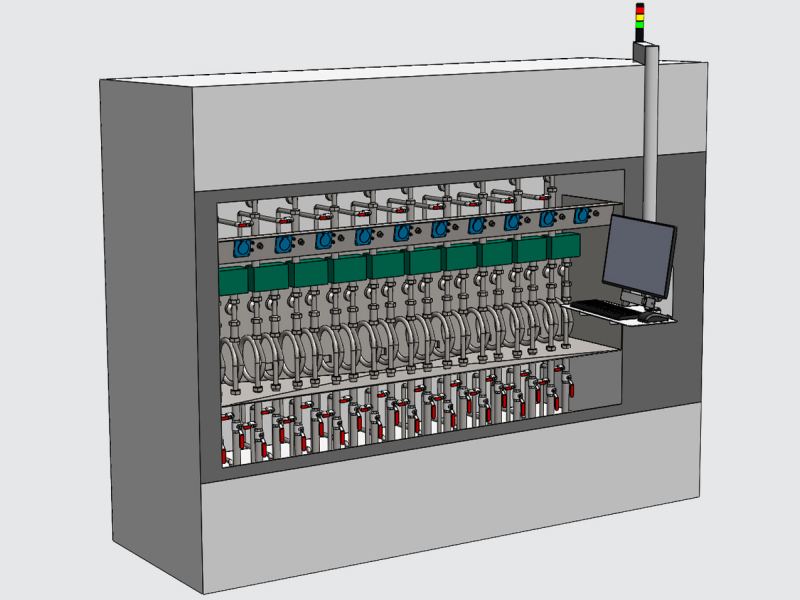

LF Technologies has developed a closed-loop water circuit that ensures the right flow and temperature homogeneity throughout the ramps. The water temperature is adjustable between 60 and 105°C.

The test area is cooled by a water/air exchanger connected to a chilled water circuit.

A closed, volume-limited stainless steel thermal chamber has been designed with a regulation system which allows for a homogeneous air circulation up to 70°C.

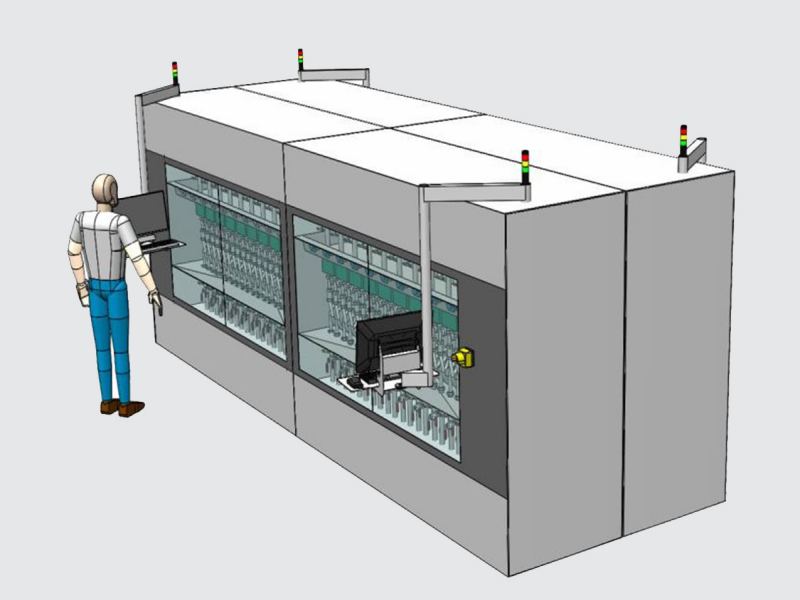

For each bench, we have installed 2 different ramps, each of which can accommodate 5 rooms. By combining the 4 modules, a total of 40 units can be installed in 8 water test conditions and 4 different air temperature conditions.

This technical solution allows :

- To have 4 modules independent of each other.

- The maintenance of one module while the others are operating.

- Simplification of the design of the machine.

- The possibility to increase the number of test lines later on by adding one or more benches.

- Simple physical separation of the benches for handling problems or space availability.

The bench is delivered with control software that allows simple and intuitive programming dedicated to the classic test functions in compliance with the valve standards.