Mechanical test benches

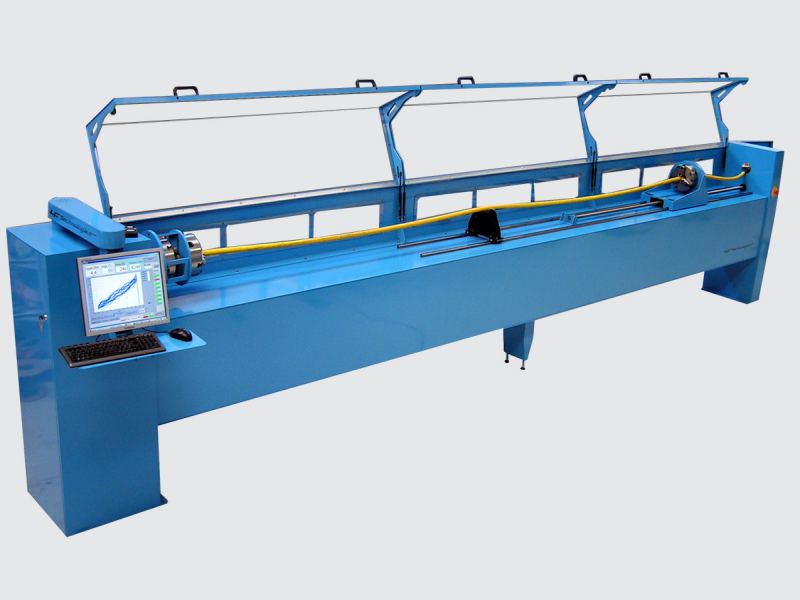

Combined traction and torsion fatigue test bench

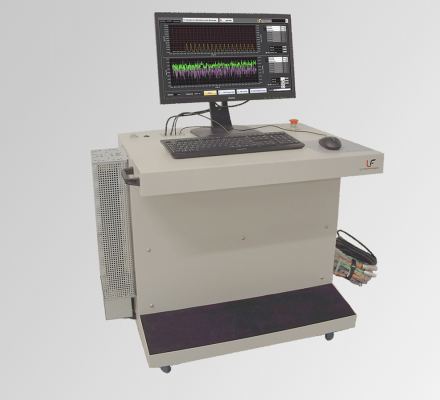

Technical description

Main functions

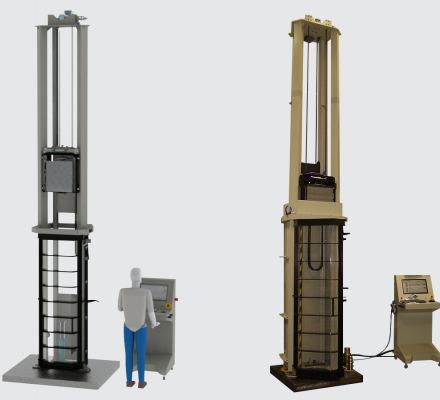

LF Technologies offers testing machines for estimating the fatigue life of components and/or complete products. Fatigue tests characterise the ability of a material to withstand cyclic loading in order to reproduce the operating conditions of the part as closely as possible.

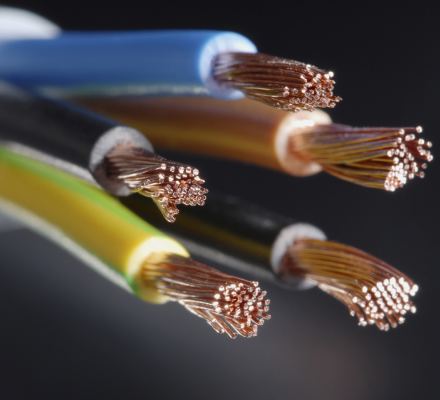

This test bench allows combined torsion and tension tests to be applied to the product under test until it breaks down in fatigue, in particular to test the mechanical resistance of electrical cables.

Operating mode

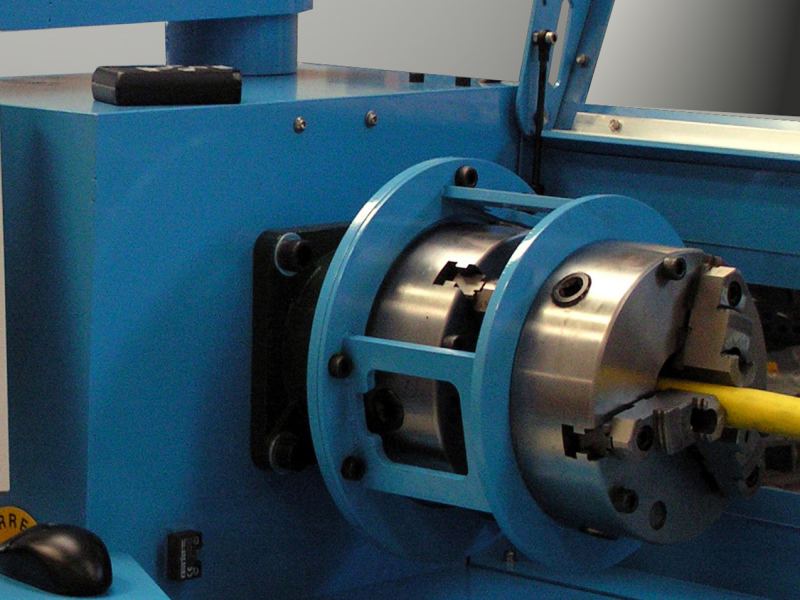

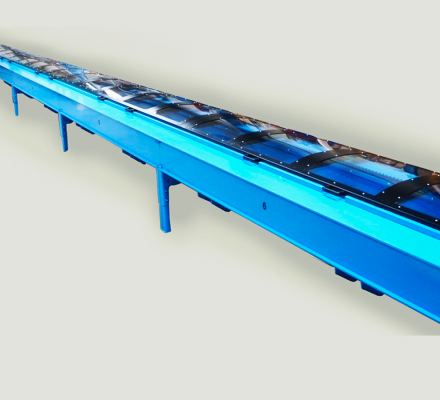

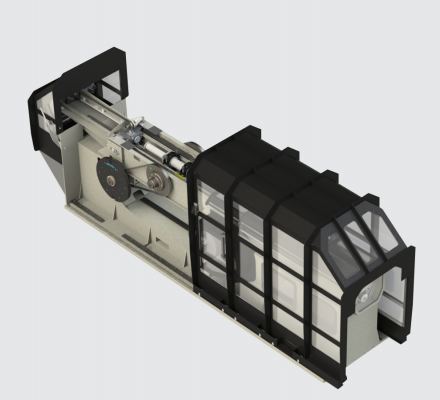

The test specimen is fixed at one end to a concentric jaw chuck which is driven in rotation, and at the other end to a translational chuck. At each end of the cable under test, dual chucks clamp the outer sheath to one chuck and the inner cable to the other.

The machine can perform combined pull and twist cycles with force, torque, position or angle control.

Advantages

- Simple and robust fixation of the product being tested by double chuck (sheath clamping + conductor clamping)

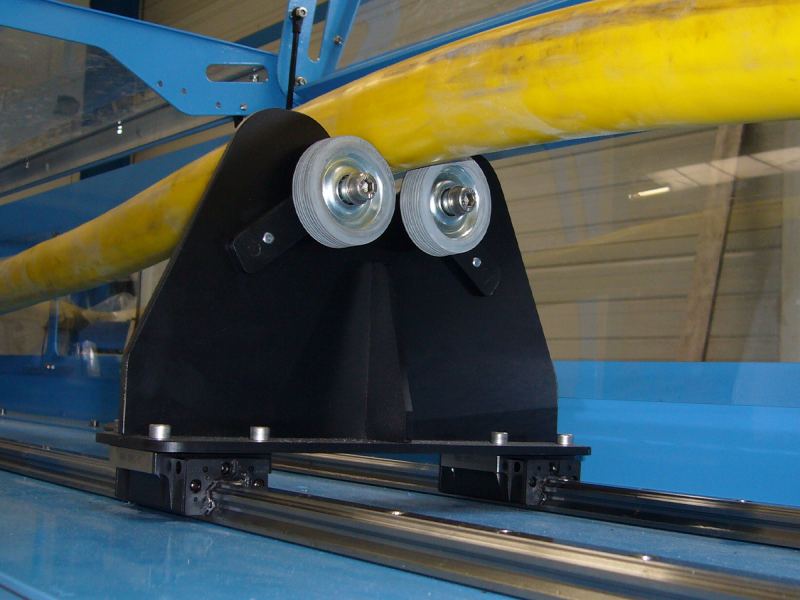

- Sliding intermediate support with rotating rollers

- Electrical continuity test assured throughout the test

- The safety covers protect the operator and the product under test. Their opening immediately stops the test