Mechanical test benches

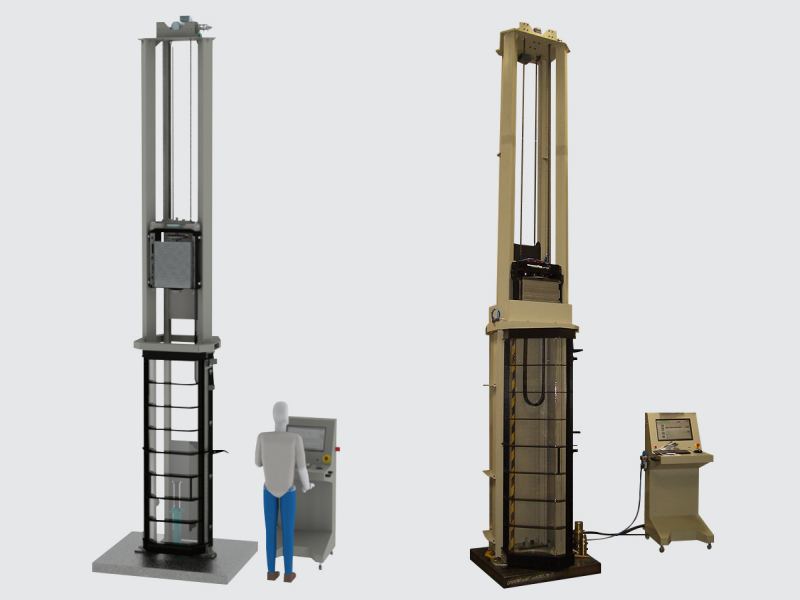

Vertical impact drop tester

Technical description

Main functions

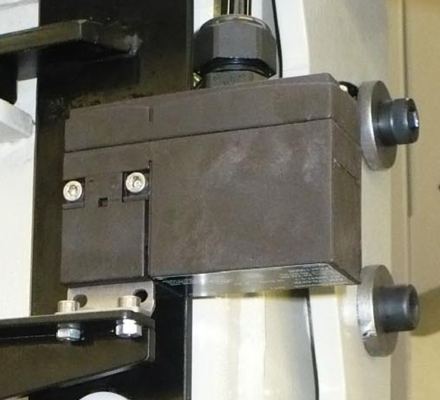

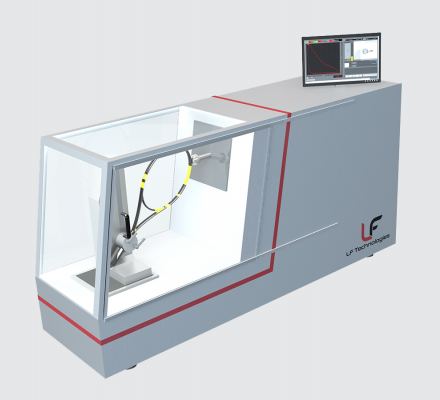

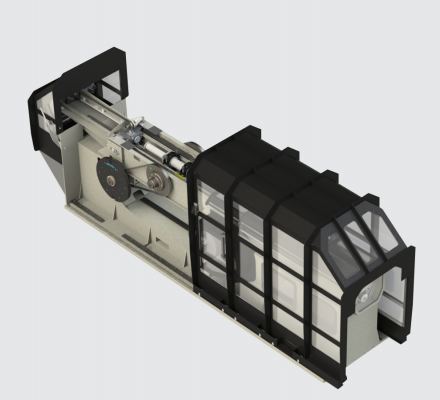

The vertical drop shaft (dynamic shock bench) is used to characterise the shock resistance of a product (specimen or component), to measure its energy absorption capacity, or to check its proper functioning after impact ("shock resistant"). The shock is ensured by a falling mass that strikes the sample with heights and mass that are adjustable by the operators. A set of high frequency sensors measures the force, position and speed of the mass during the impact. The machine is completely safe, thanks to its protective casing system, which prevents any risk of projection during impact tests.

Operating mode

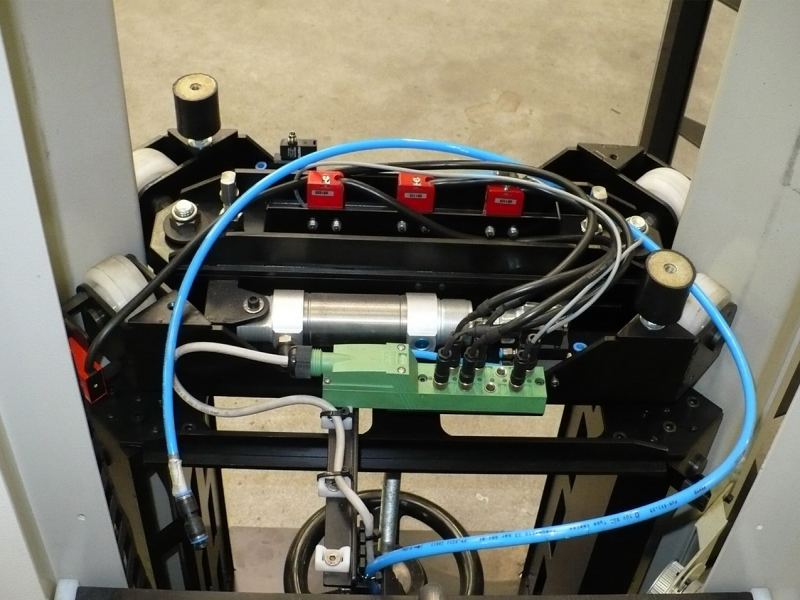

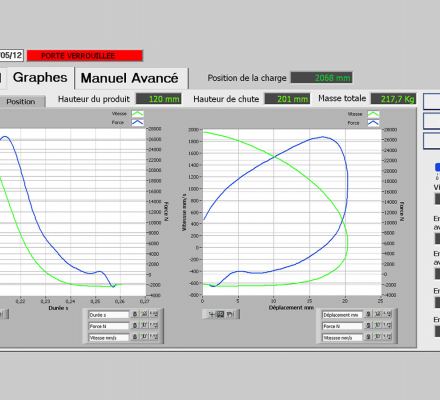

The user positions the test specimen safely. After selecting the mass value and drop height, the machine automatically adjusts and drops the mass onto the specimen. Height, velocity, force and energy measurements are automatically recorded at high frequency during the impact. An automatic analysis system calculates the impact energy, the absorbed energy and the released energy.

Advantages

- High frequency recording of measurements

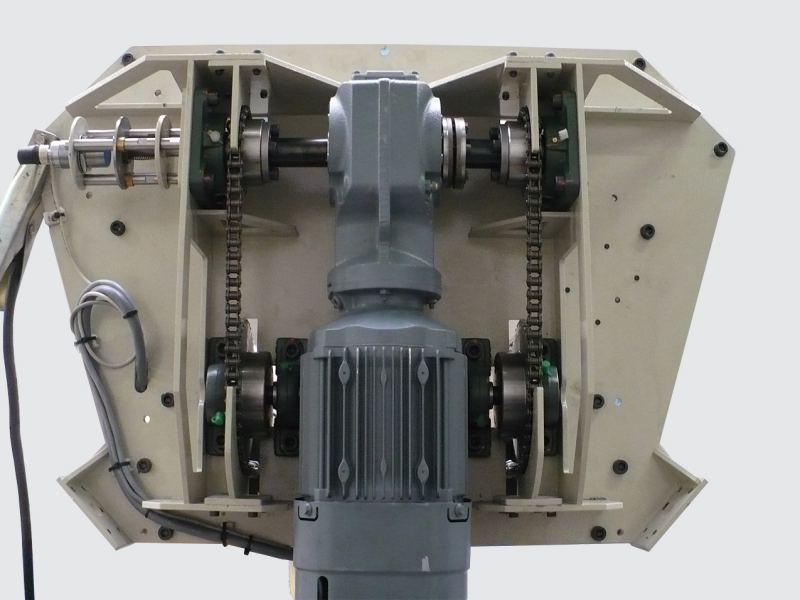

- Precise drop height adjustment by automated lifting

- Automatic release system fully secured by a certified automaton

- Safety striker ensuring total protection for the operator