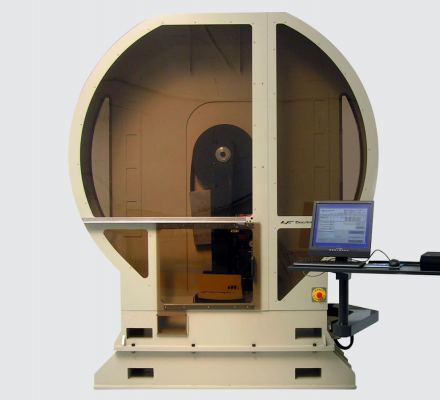

Mechanical test benches

Torsion test bench

Technical description

Main functions

The torsion test bench can test samples up to 1,000 Nm and 400 °/min, according to programmable cycles, until they break.

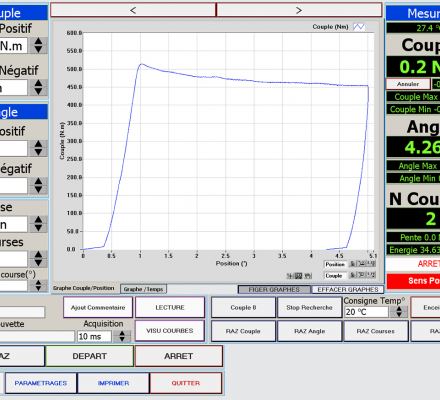

It automatically measures torsional stiffness and deformation energy.The specimen is fixed to a shifting head, allowing to test samples of variable lengths up to 500 mm.

The torque measurement is carried out by a strain gauges torquemeter, the angle of deformation by a high resolution encoder.

Operating mode

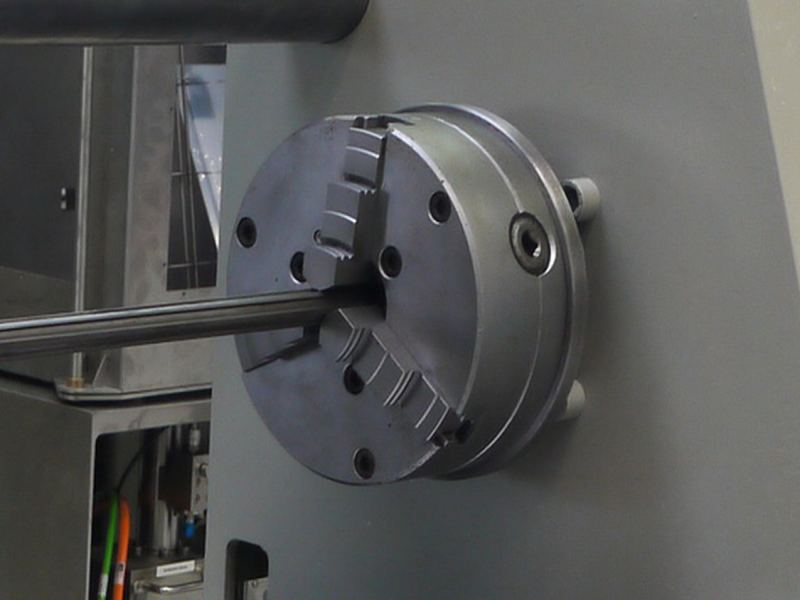

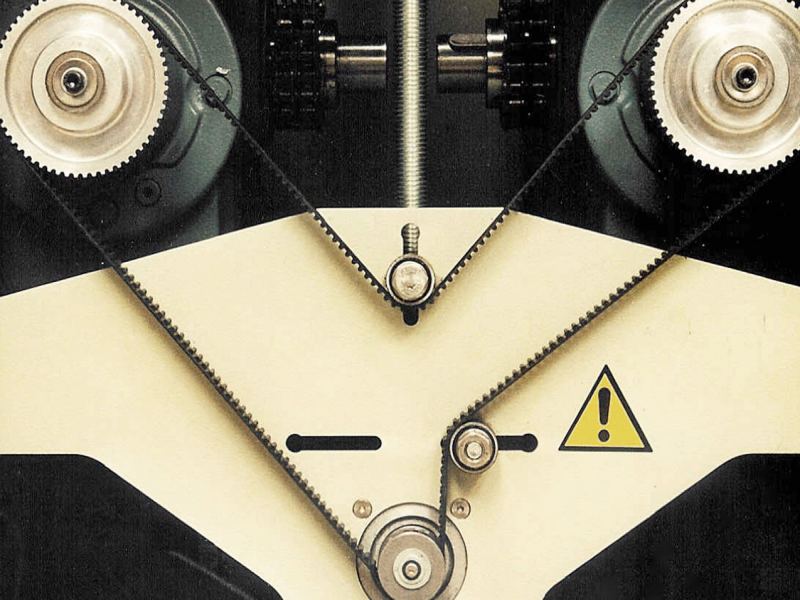

The sample to be tested is fixed on two concentric chucks. The first chuck, fixed in rotation, is mounted on a shifting head with adjustable sliding position. The second chuck is driven in rotation by a brushless geared motor equipped with an anti-backlash system. The user sets a rotation speed, min and max angle or min and max torque of the test as well as a number of cycles. The software automatically measures the coefficient of torsional stiffness as well as the energy absorbed by the sample at each cycle.

Advantages

- Simple fixing of the product thanks to standard interchangeable chucks

- Simple programming of automatic cycles with simple parameters

- Backlash adjustment; zero backlash thanks to a double pre-load transmission

- High resolution of angular measurement

- Adjustable length thanks to a sliding head equipped with a brake