Hydraulic test benches

Endurance test bench for solenoid valves

Technical description

Main functions

The LifeEV is an endurance test bench for estimating the service life, performance and hydraulic characteristics of solenoid valves for electronically opening and closing sanitary fittings.

Tests are performed to meet EN15091 standards.

Automatic test functions:

- Management of water supply solenoid valves (hot or cold on each supply)

- Automatic temperature cycling

- Solenoid valve opening/closing command with adjustable pulse duration

- Automatic search for the minimum electrical pulse duration to open the solenoid valve.

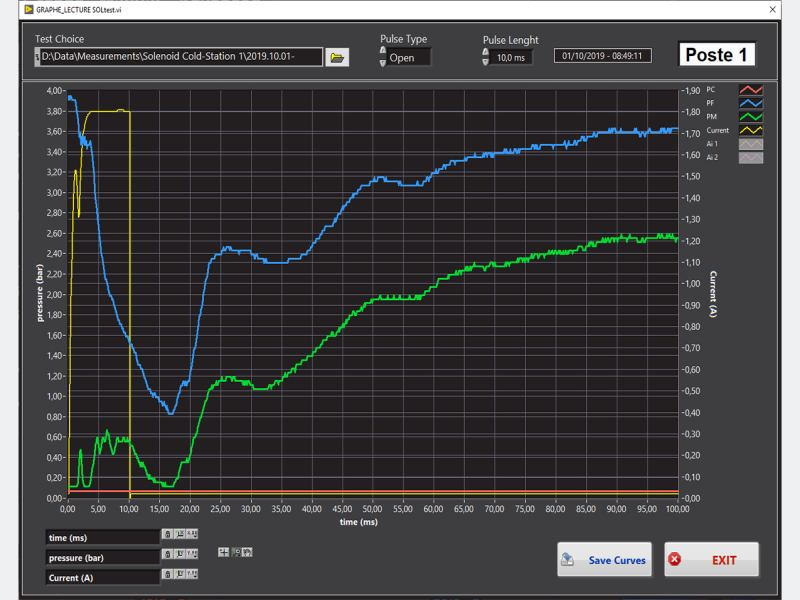

- Water hammer test on solenoid valve closure, with peak pressure measurement

- Static pressure test

Operating mode

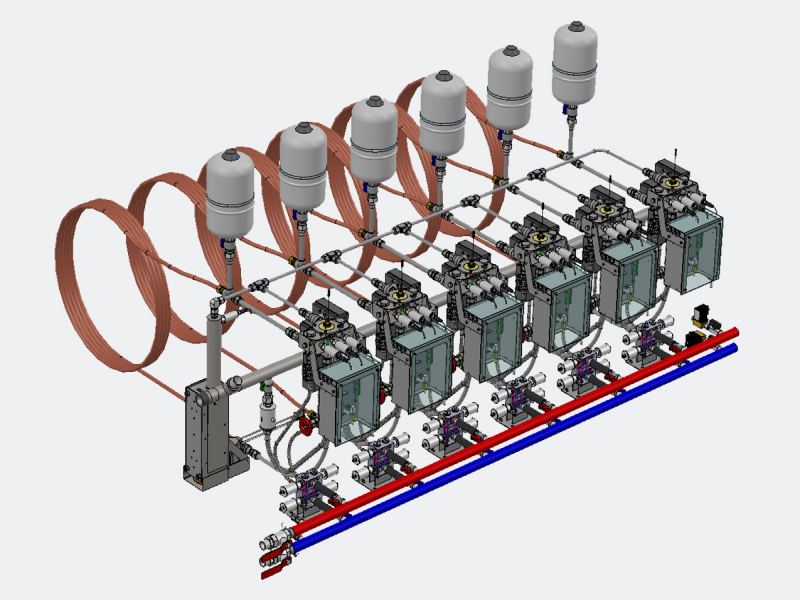

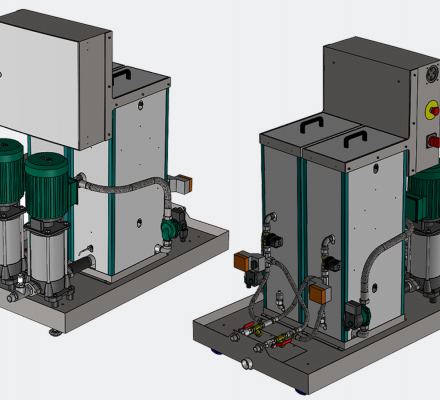

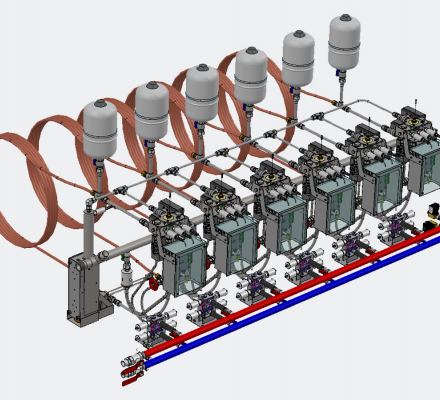

The equipment is a test bench equipped with several modules (from 2 to 6), designed to perform performance and endurance tests of solenoid valves and valve components.

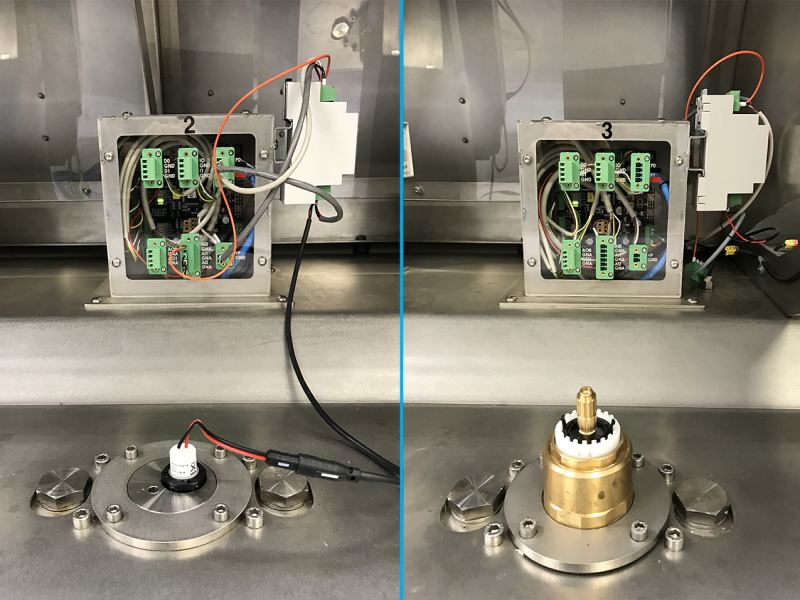

Each product under test is mounted in a specific tool, connected to a hot and cold water supply and a piped mixed water outlet. A solenoid valve on the outlet is used for leak testing.

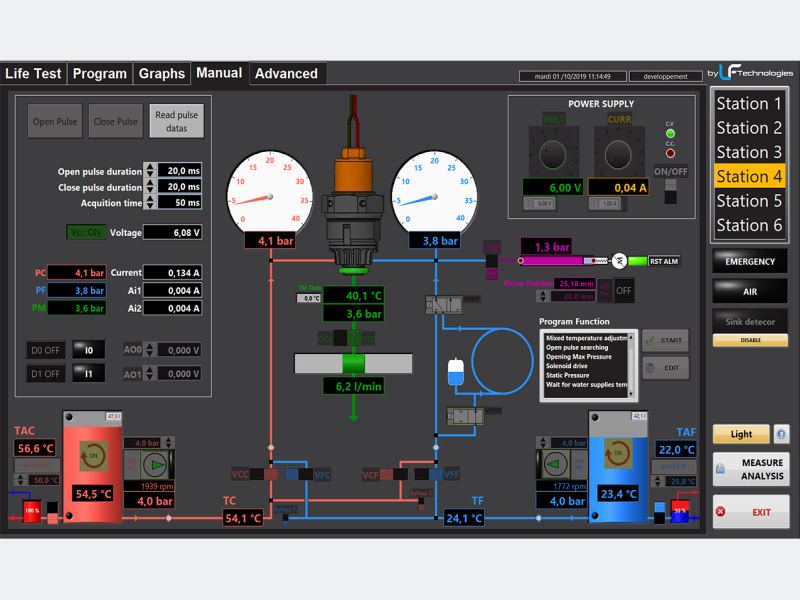

For the solenoid valve tests, each solenoid valve is connected to a specific power supply, with adjustable voltage, adjustable electrical pulse duration, and high frequency signal acquisition (voltage and current). This acquisition is synchronised with high frequency pressure measurements. This solenoid valve control module enables the opening and closing times of the solenoid valve to be tested as a function of the supply pressure and the characteristics (voltage and pulse duration) of the control signal. This system, coupled with the "Water hammer coils" module, allows the measurement of the pressure peaks (water hammer) generated by the solenoid valve when it closes.

Each test line is equipped with temperature inversion valves allowing each inlet of the module to be supplied with hot or cold water for temperature cycling.

The bench is connected to two hot and cold water inlets. The temperature generation is done outside the bench. The hot and cold water supply pressures are provided either directly from the mains supply to the bench or by an external pressure generator (optional).

The software performs all performance and endurance tests by simple programming.

Static pressure generator

The static pressure generator consists of a motorised plunger associated with a pressure sensor. The pressure is controlled by the movement of the piston which compresses the water in the cylinder, whatever the test conditions: product expansion, temperature changes, leaks (within the limits of the system's flow rates and power).

The static pressure generator is common to all test lines. Each test line is equipped with a solenoid isolation valve allowing the static pressure to be connected or not to the product under test.

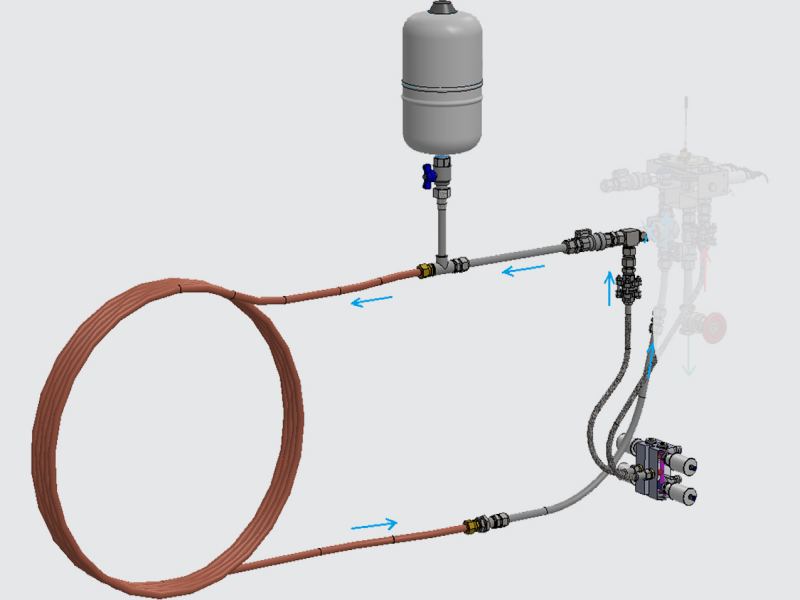

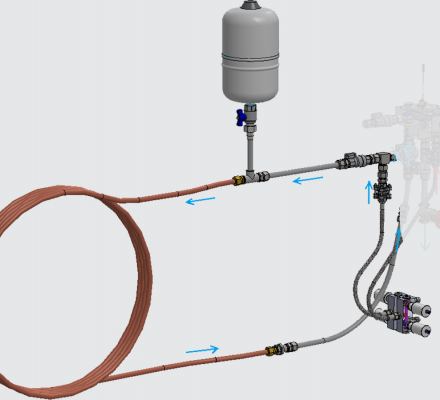

Water hammer coils

Water hammer coil systems are used to simulate the inertia of the water upstream of the solenoid valves, in order to measure the water hammer generated by the solenoid valve during shutdown tests.

Dimensions of a post |

LifeEV2 | LifeEV4 | LifeEV6 |

Width |

1 760 mm | 2 080 mm | 2 400 mm |

Depth |

1 300 mm | 1 300 mm | 1 300 mm |

Height |

1 400 mm | 1 400 mm | 1 400 mm |

Weight |

200 kg | 250 kg | 300 kg |

Benefits

- Independent or synchronised testing

- Standards-compliant testing

- Flexibility