Mechanical test benches

Tube peel test bench

Technical description

Main functions

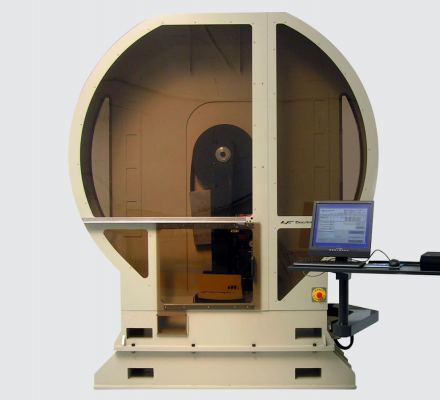

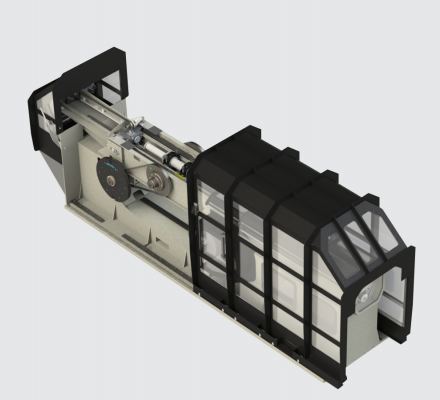

The pipe peel tester is used to test the peel strength of protective coatings on pipeline pipes. The stainless steel machine is self-contained and powered by a standard battery. It records the peel force over a sample length of up to 200mm. The pipe peeler is also equipped with a carrying case with force and displacement monitor and report printout.

Operating mode

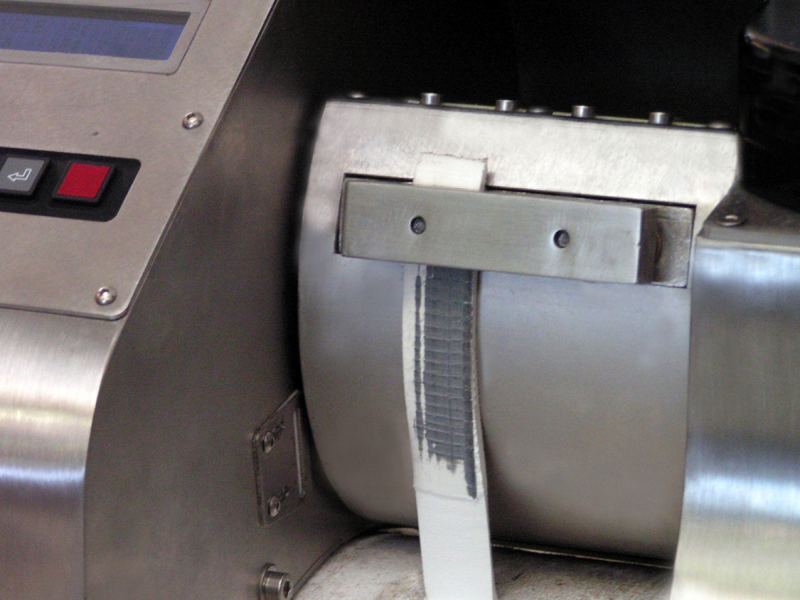

The machine is equipped with a gripper that allows the end of the sample to be picked up. This clamp is inserted into a Ø 150 mm reel. The driving wheels of the machine, associated with a light barrier, allow the torn-off part of the sample to be held in a radial position, without a return roller. Two removable side pulleys allow the machine to be strapped onto the tube if required. A 4-button keypad controls the clamp (un)clamping, drum rotation, machine movement and cycle.

Advantages

- Autonomous and portable worksite machine with transport case

- The use is simple and intuitive, including for an unskilled operator

- No tools are needed thanks to the automatic clamping of vices, jaws or clips

- Standard batteries (makita)