Impact pendulum – Impact Charpy, Izod

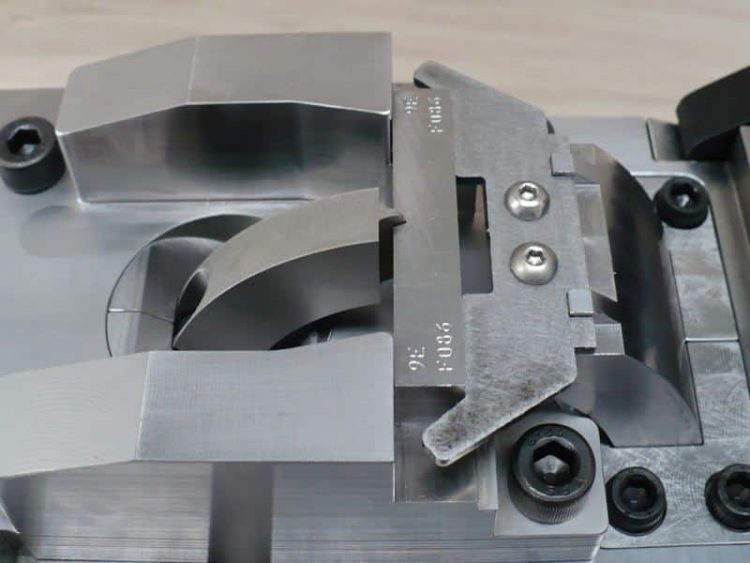

- High precision thanks to a monoblock specimen holder equipped with an automatic centering device

- Quick release (less than 5 seconds) between placement and breakage of the specimen

- Total operator safety thanks to redundant security systems

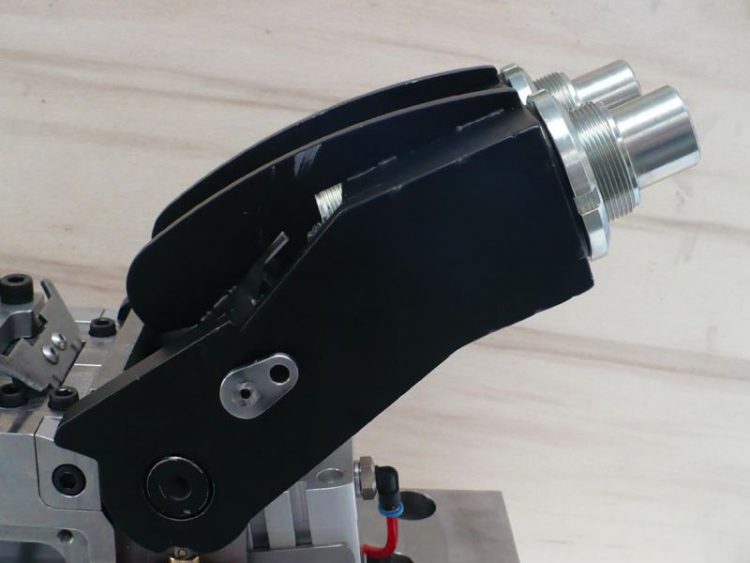

- Motorized arm to ensure precise positioning and on-the-fly hooking after the test

Products tested

Sector of activity

Main functions

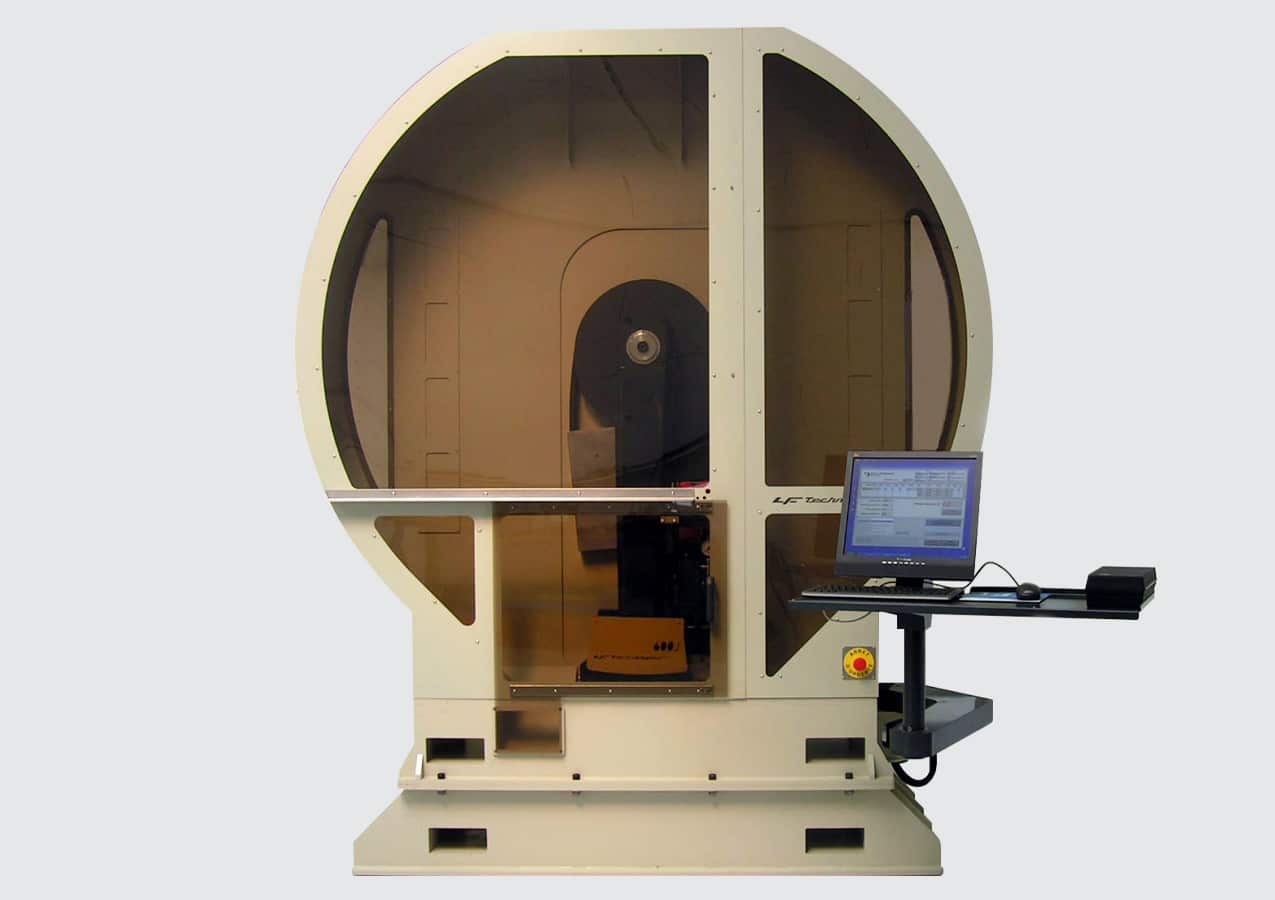

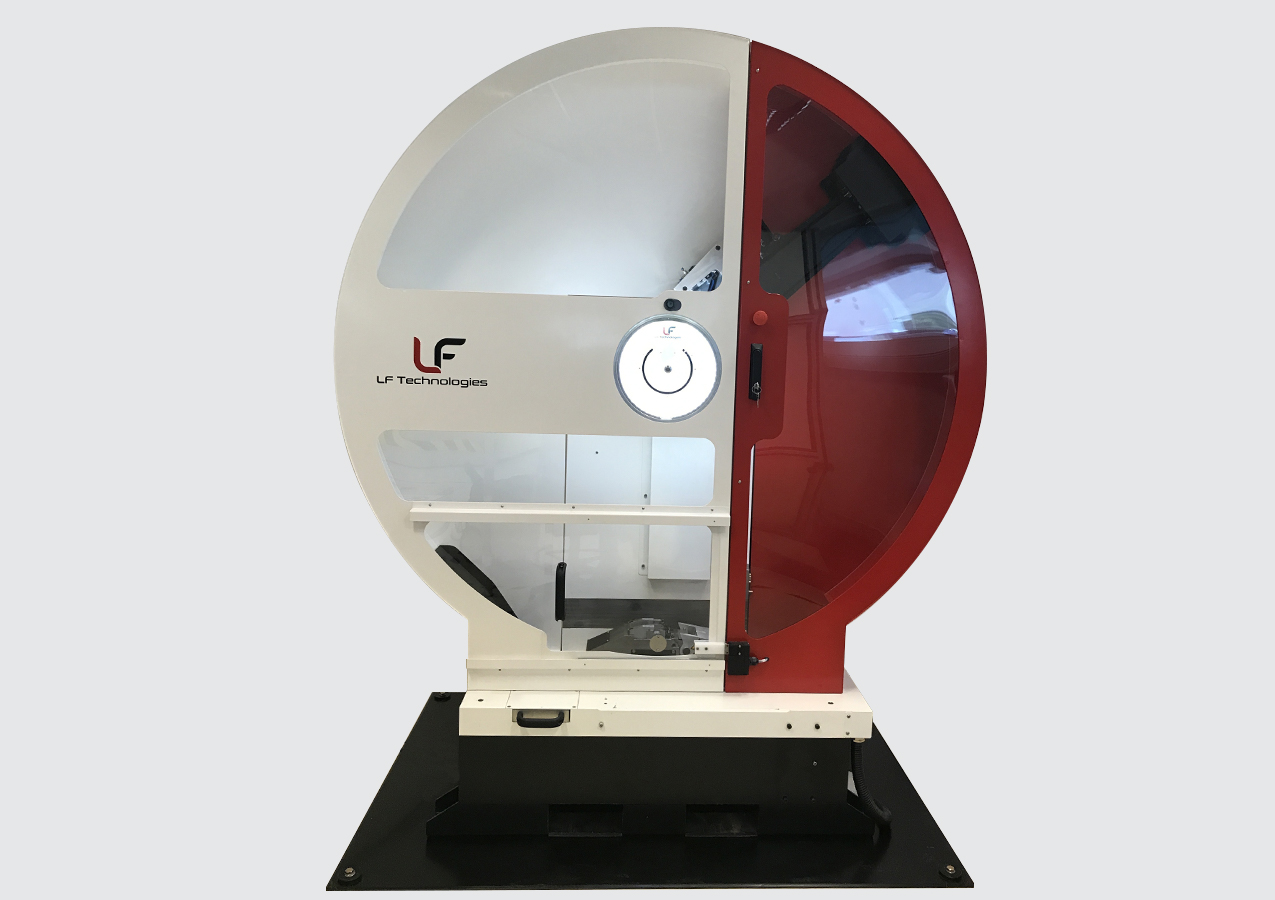

Impact resistance is one of the most important properties to consider when designing a part or appliance. The impact pendulum test machine is used to determine the impact strength of a sample against a shock applied to it in accordance with ASTM and ISO standards. Impact pendulum test machines perform precise and repeatable impacts on a wide range of materials to determine the mechanical and physical characteristics of metals, polymers, composites, whether for R & D or quality control in production. Our machines carry out Charpy and Izod tests, which meet international standards. Our machines perform Charpy and Izod tests, which meet international standards.

Operating mode

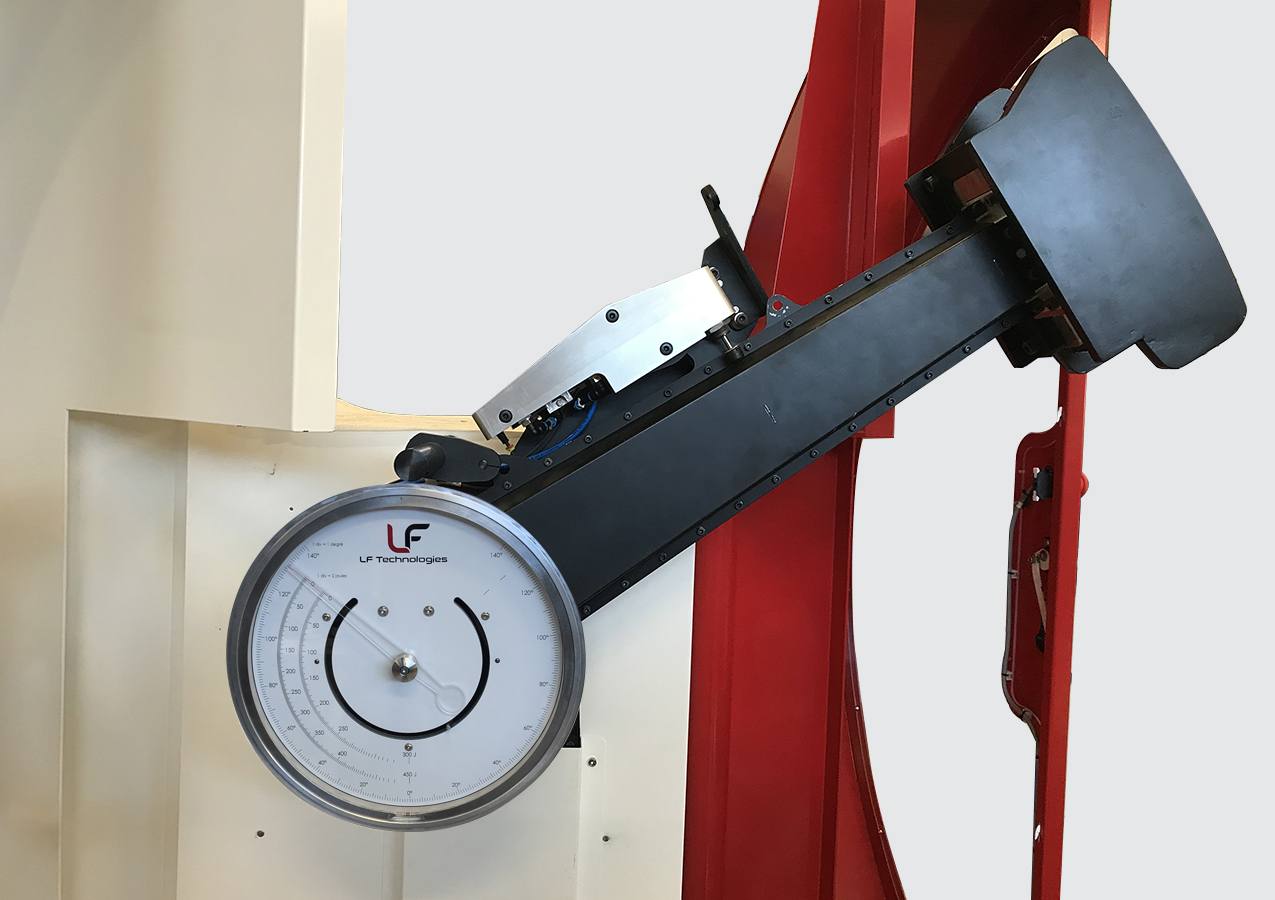

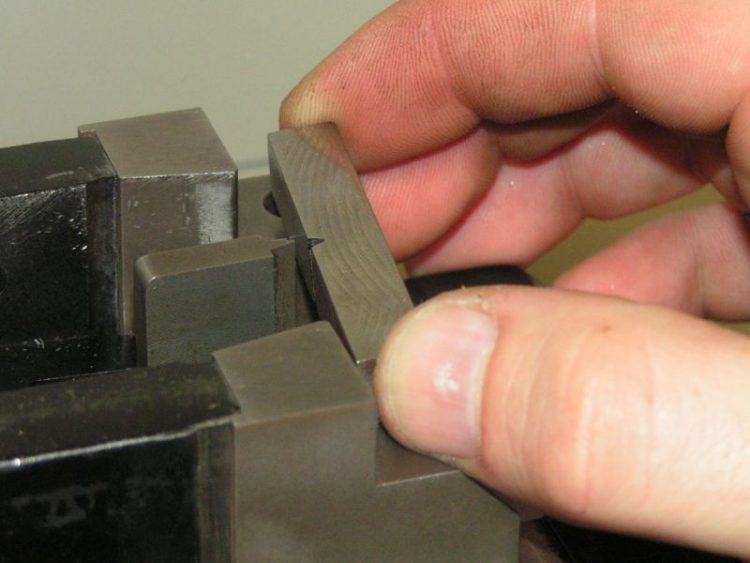

The automatic specimen centering system ensures a simple and effective use of the impact pendulum. The specimens are impacted within 5 seconds following their removal from the temperature unit. The use is simplified thanks to the rapid change of the knife and specimens supports.

The motorized impact pendulum is equipped with a pneumatic hammer release system. The hammer resetting process is motorized for a better ease of use. A protective casing protects the operators during the displacement of the hammer.

Bench developed to meet these standards:

Impact pendulum – Impact Charpy, Izod

Pendulum impact tester for carrying out tests on standardised Charpy and Izod impact specimens, in accordance with ISO 148.

Benefits of the Impact pendulum – Impact Charpy, Izod

High-precision support

High precision thanks to a monoblock specimen holder equipped with an automatic centering device

Safety in use

Total operator safety thanks to redundant security systems

A motorized arm

Motorized arm to ensure precise positioning and on-the-fly hooking after the test

Automatic centring by notch

Standardized Charpy and Izod impact testers for all materials.

Quick release

Less than 5 seconds between insertion and breakage.

TECHNICAL CHARACTERISTICS of the Impact pendulum – Impact Charpy, Izod

Spécifications | MCMP 300 | MCMP 450 | MCMP 600 |

Caractéristiques de l'appareil | |||

Energie disponible (pneumatique, électrique et hydraulique) | 300 J | 450 J | 600 J |

Vitesse réglable | jusqu’à 6 m/s | jusqu’à 6 m/s | jusqu’à 6 m/s |

Résolution mesure d’énergie | 0,02 J | 0,02 J | 0,03 J |

Pilotage par PC | |||

Gestion des essais : | - Calcul - Archivage des résultats | - Calcul - Archivage des résultats | - Calcul - Archivage des résultats |

Accrochage auto. du pendule par bras motorisé dynamique | |||

Double système d’accrochage | |||

Système de centrage auto. de l’éprouvette | |||

Déclenchement auto. de l’essai par fermeture de la porte | |||

Géométrie du couteau | |||

Largeur du couteau | < 18 mm | < 18 mm | < 18 mm |

Angle du couteau | 30° (± 1) | 30° (± 1) | 30° (± 1) |

Rayon du couteau | 2 mm (+ 0,5 - 0) | 2 mm (+ 0,5 - 0) | 2 mm (+ 0,5 - 0) |

Géométrie des appuis | |||

Distance entre appuis | 40 mm (+ 0,5 - 0) | 40 mm (+ 0,5 - 0) | 40 mm (+ 0,5 - 0) |

Rayon des appuis | 1 mm (+ 0,5 - 0) | 1 mm (+ 0,5 - 0) | 1 mm (+ 0,5 - 0) |

Dépouille des appuis | 11° (± 1) | 11° (± 1) | 11° (± 1) |

Dimensions | |||

Hauteur | 2 560 mm | 2 560 mm | 2 560 mm |

Largeur | 2 100 mm | 2 100 mm | 2 100 mm |

Profondeur | 800 mm | 800 mm | 800 mm |

Poids | = 2 000 Kg | = 2 000 Kg | = 2 500 Kg |

Customer applications

Would you like to find out more about mechanical test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Explore our complementary products to get the most out of your impact pendulum !

Discover innovative solutions to further enrich your experience and optimize your results.