Hydraulic test benches

Thermal shock and cyclic pressure test bench for pipes

Technical description

Test bench for the resistance of pipes to hot water circulation, temperature cycles and static pressure

Main functions

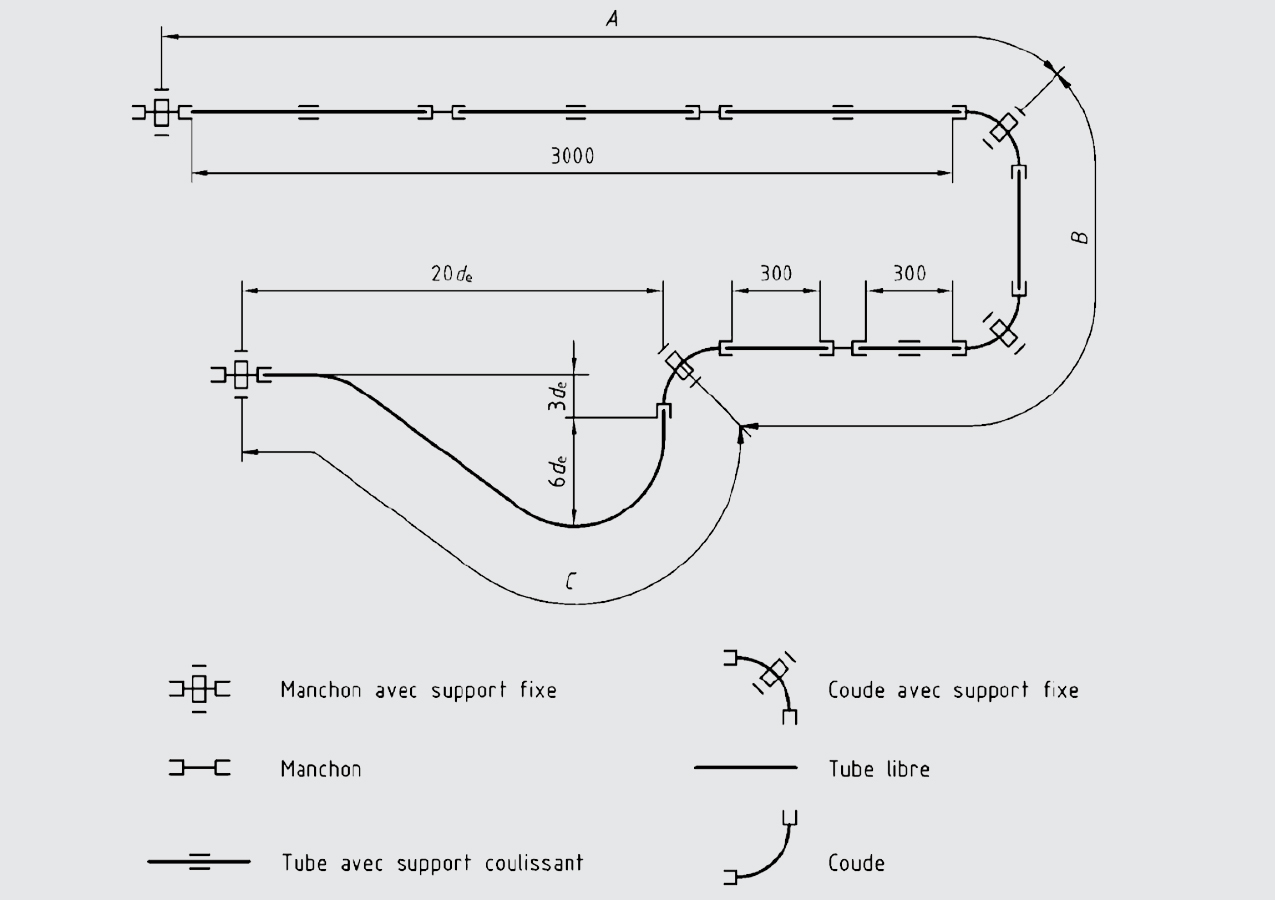

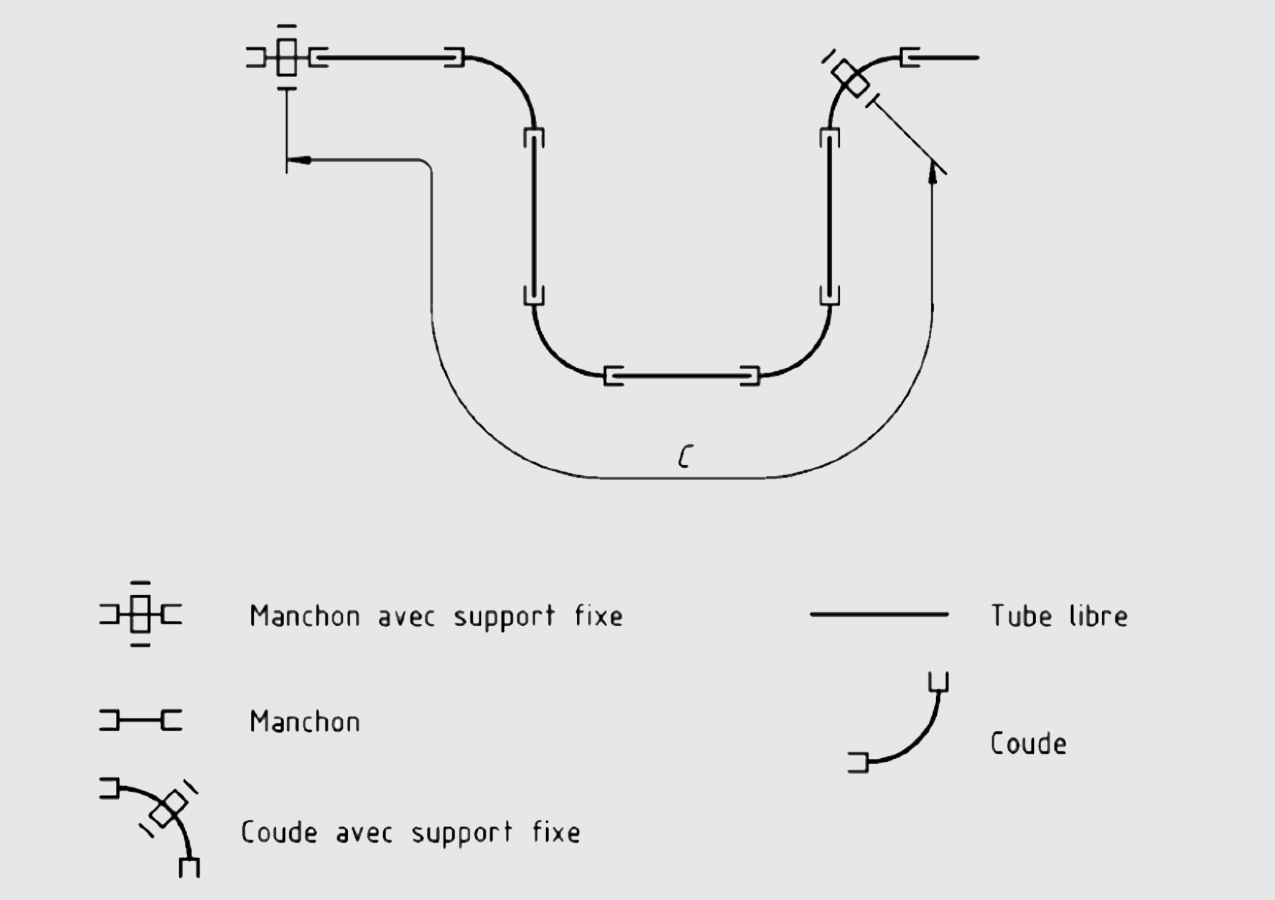

The "ThermShock" is a test rig for testing the resistance of pipes to hot water circulation, temperature cycling and static pressure, according to EN 12293 or EN ISO 19893.

It consists of a hot and cold water generation system and a test area for fixing the tested pipes in accordance with the standards.

Operating mode

TEST AREA

The pipe elements to be tested are fixed to a "wall" in the test area on profiles using tooling. The different types of tooling allow for full fixation or allow for degrees of freedom in accordance with the standard. Part of the pipe under test can be put under tension by means of a manual tensioning system equipped with a load cell (up to 20,000N).

The test area is equipped with a hoist that facilitates the placement of heavy pipe components.

This area is enclosed by transparent doors which prevent the risk of burns and water splashes in the event of a leak in the pipe being tested.

The lower part of the test area consists of a leakage recovery sink. In the event of a leak, an automatic detection system stops the test immediately.

The test area is equipped with a cooling system to maintain the air in the area at a temperature <40°C.

HOT AND COLD WATER UNIT

The pipe is connected at both ends to the hot and cold water generation unit.

This unit has 2 tanks (1 hot and 1 cold), which are temperature-controlled. The heating and cooling energy supply is provided by superheated water and chilled water loops (not included) connected to the tanks by heat exchangers.

The hot water circulation circuit is also equipped with an electric heater, which ensures that the temperature is maintained up to 110°C.

The system ensures :

- the generation and regulation of pressure, static or dynamic

- the regulation of a circulation flow rate

- switching from the cold water circuit to the hot water circuit and vice versa, thanks to automatic valves (thermal shocks)

- Filling and emptying the pipes.

The thermal shock generation system is optimised to minimise energy losses during changeover by minimising the mixing of hot and cold water. The temperature boost system compensates for the thermal inertia of the pipe itself, to ensure a more accurate thermal shock.

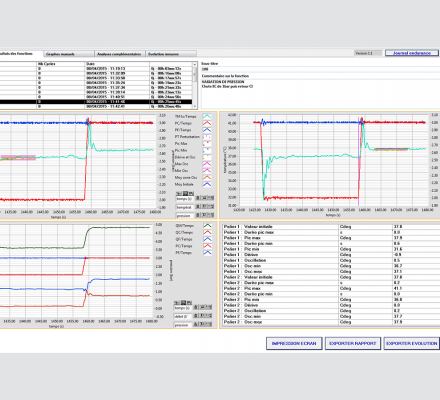

CONTROL UNIT

The unit is controlled by a computer equipped with a dedicated HMI.

Main functions:

- Active synoptic and manual control of all bench elements

- Configurable graphics for all measurements

- Editing, saving and reading of programmable test sheets, to set up automatic tests

- Management of automatic tests with display of the progress and estimation of the remaining time

- Measurement calibration system

Benefits

- Energy saving

- Flexible testing (static pressure, hot water circulation, temperature cycling)

- Easy to implement tests

- Automatic test programs

- Automatic test report

- Removable and mobile test area