Hydraulic test benches

Pressure and temperature cycling

Technical description

Main functions

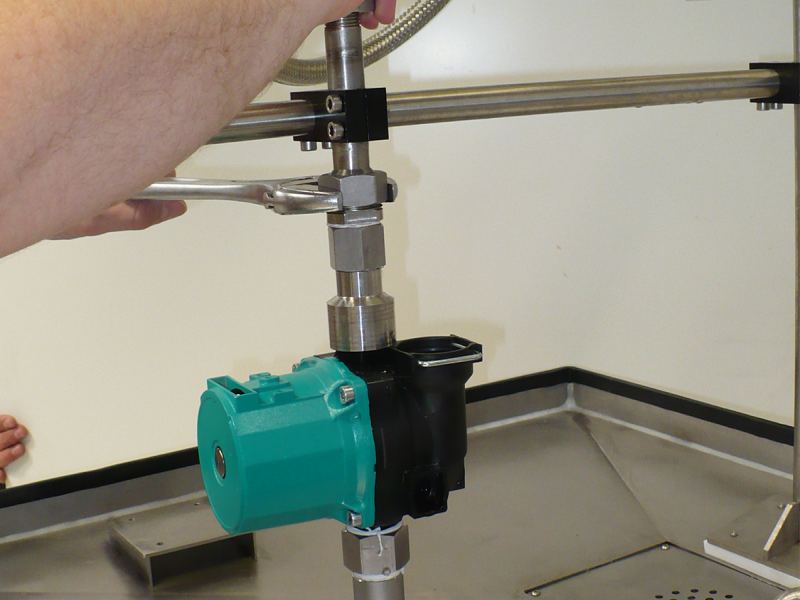

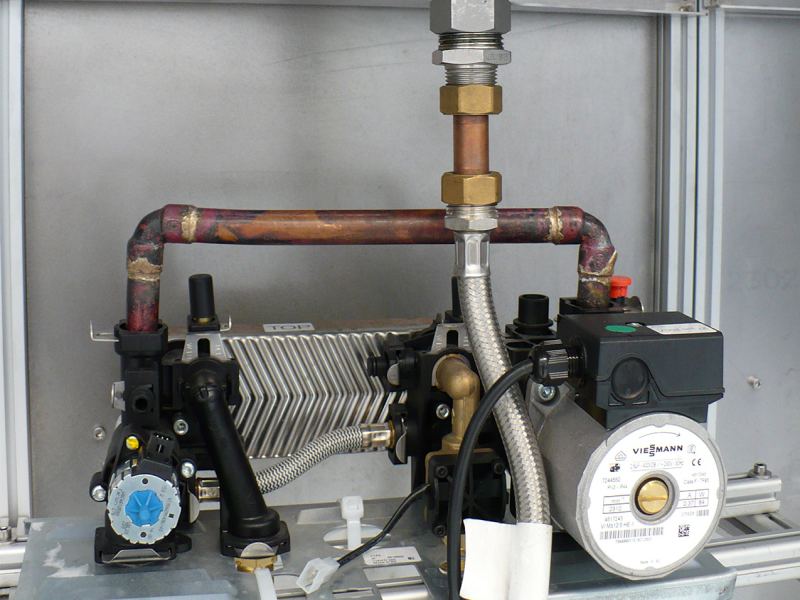

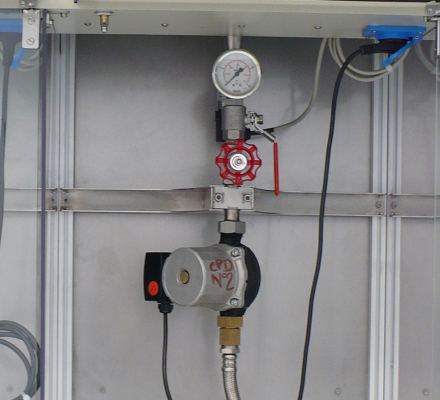

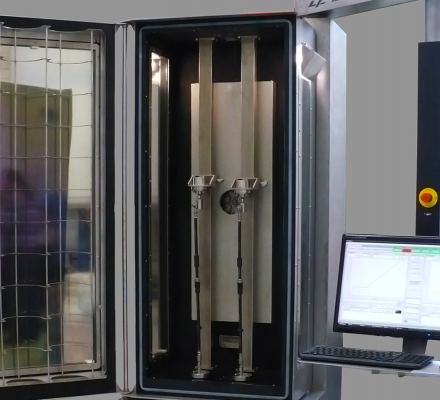

The test loop enables testing the resistance to pressure and temperature of pumps, circulators, valves or sanitary appliances in continuous operation. The software allows to monitor in a controlled manner the progressive degradation of the tested sample.

The test bench is primarily intended for research and development laboratories wishing to optimize product design.

Operating mode

Once installed, the device is supplied with water and undergoes cycles of pressure and temperature variations. Thanks to low volumes of hot and cold water, the test bench offers a very energy-efficient operation compared to conventional solutions on the market.

Advantages

- Large energy savings thanks to the optimization of the exchange of hot and cold water during the temperature shocks

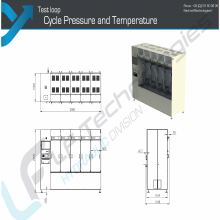

- Ability to test multiple devices simultaneously and independently