Customer

Our client manufactures innovative medical equipment for patients with chronic respiratory diseases.

Manufactured product

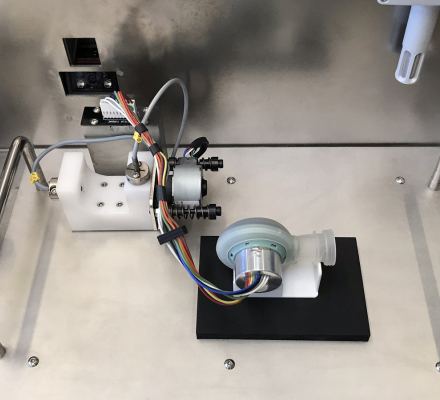

Respiration assisting equipment component.

The turbine-engined is used to generate the flow of air sent to the patient. The breathing apparatus adapts the flow and pressure of the airflow by controlling the turbine speed, according to the patient's needs.

Objective

Control breathing assistance turbine’s performance at several operating points of flow and pressure..

Problematic issues

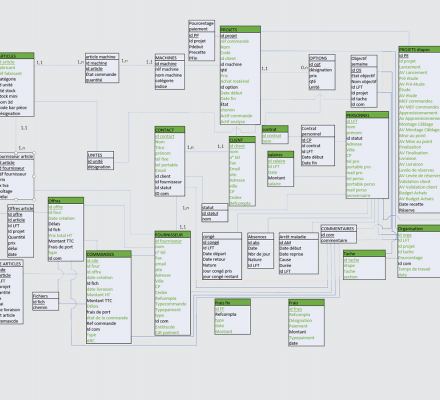

Our client is developing a new product, he wants to test the conformity of the engine and the turbine before the final assembly. He also wants Research and Development tests to certify improvements and make the control more reliable.

Solution and result

Calculation was made and showed that the control basis was inconsistent with reality and that it led to “false negatives”. So, in reality, it could potentially set aside some good parts.

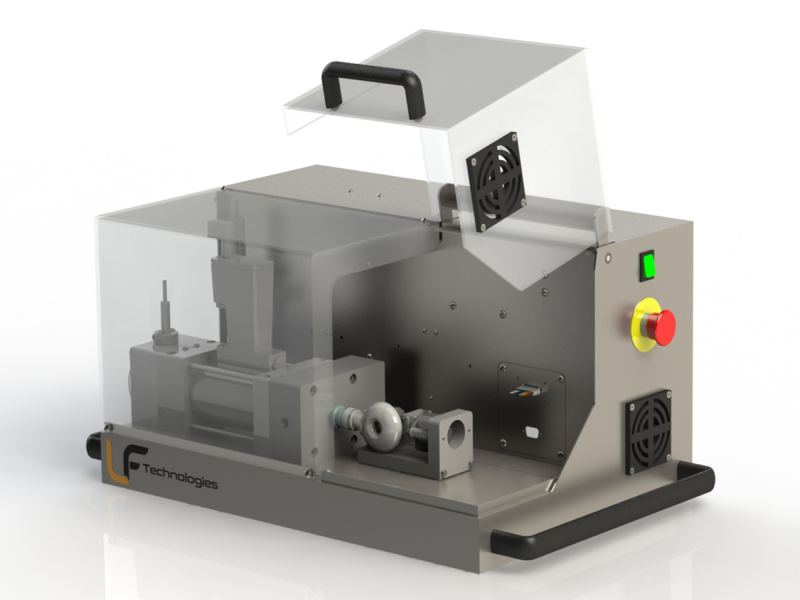

LF Technologies made a system that could fix precisely one of the parameters (speed) thanks to an automatic control and make tests on a full curve (flow, pressure, …) instead of operating points (too restrictive) thanks to a proportional valve especially designed to ensure progress and get a pressure loss close to zero in case of full opening.

Furthermore, product’s automatic fixation whiped out measurement errors linked to the deformation of the flexible part.

LF Technologies made an automatic and portable test bench, able to create flow and pressure curves at different rotation speeds with a pressure loss of only 10 mbar for 400L/min.