Customer

Our client, a market leader, is a producer and supplier of electricity in France and Europe for companies, local authorities and individuals.

Tested product

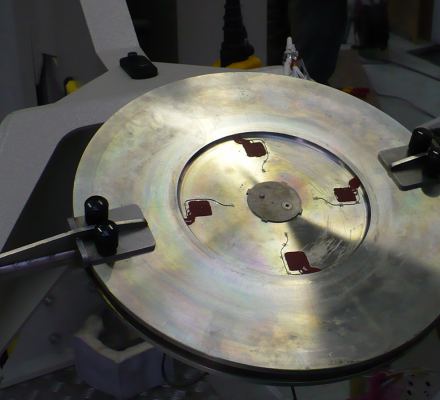

The test samples (instrumented mock-ups) represent labyrinth seals of nuclear primary pumps.

Labyrinth seals belong to the family of non-contact seals, whose purpose is to prevent the transfer of a gas or liquid.

The mock-ups consist of a stainless steel disc drilled through the centre, welded by electron beam into a retaining ringg. The mock-up is fitted with crack starters.

Objective

To study the propagation of cracks in plasticised media, due to thermal shocks between the 2 faces of the tested part.

Problematic issues

The function of the test rig is to test the mock-ups defined above, hold them under a load of 2000 kN and apply temperature cycles to both sides independently. The rig must be able to maintain the temperature of both sides of the model, despite the thermal convection of the model, which requires a large amount of heating and cooling power.

Solution and result

The test specimens are stressed by applying a temperature differential of 100°C between the two faces, which generates stress and causes cracks to propagate

This temperature differential is achieved by circulating water at 100°C on one side and 200°C on the other, by means of two water circulation loops (one per side), each equipped with a pump, an exchanger, a heater and a diffuser (heating ring also known as the outer ring). The circuits are pressurised to keep the water in liquid phase.

Stress cycles are created by bringing the whole device to 100°C, then causing the temperature differential again.

The complementary ring remains at 200°C on both sides. It is kept flat by a 2000 kN load, applied via a press with a hydraulic cylinder (250 T, 300 mm stroke) and its control unit.

The bench was designed symmetrically so that the faces of the model could be inverted.