Mechanical test benches

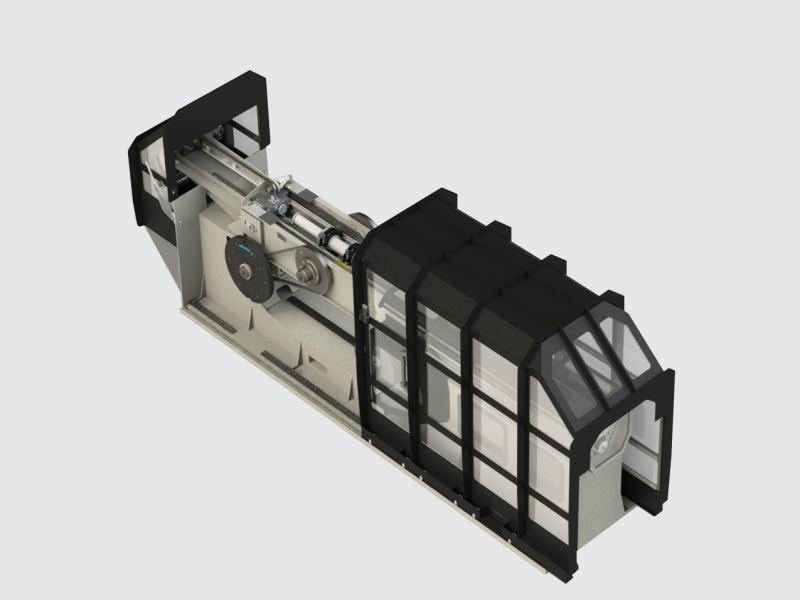

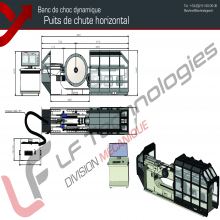

Horizontal impact drop tester

Technical description

Main functions

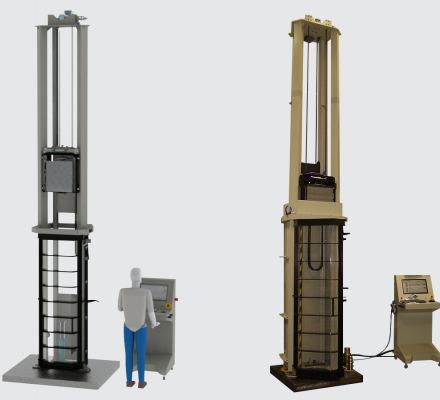

The horizontal impact drop tester (dynamic shock test bench) allows to produce linear shocks with adjustable energy, speed and mass.

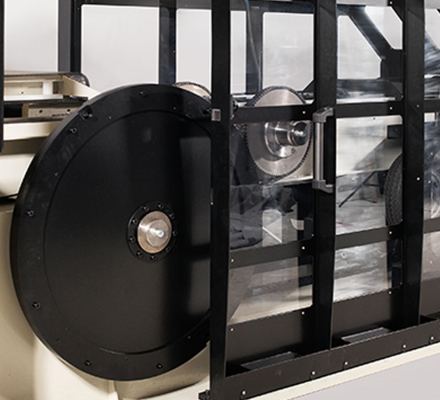

Its revolutionary heavy weights simulation system makes it possible to carry out impact tests corresponding to a collision with a mass of 40 to 200 000 kg at a speed adjustable from 0.5 to 9 m/s thanks to flywheels of a mass of less than 200 kg.

A high-frequency acquisition ensures the recording of the force/position curve at 100 kHz and the calculation of the absorbed and restored impact energies.

Operating mode

Thanks to the calculation module the user selects a weight to be simulated and an impact speed or energy. The software then automatically indicates which flywheel to use.

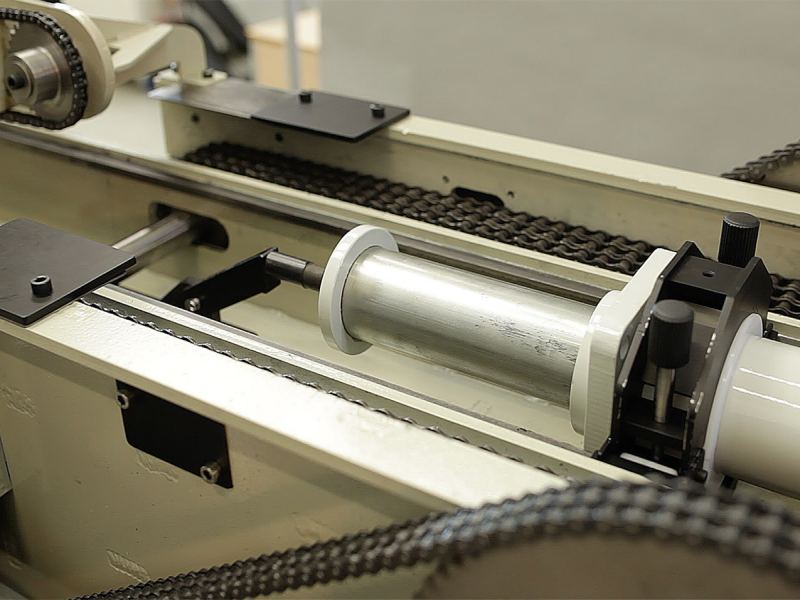

The automatic launcher system accelerates the flywheels to the right speed, the striker is automatically engaged on the flywheels motion.

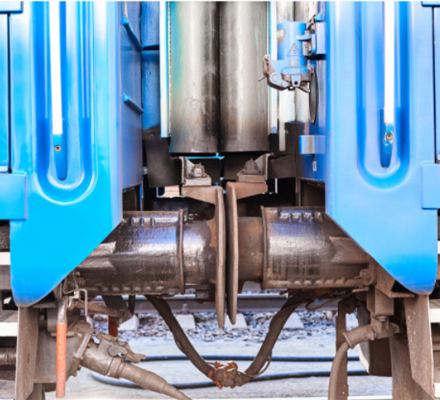

The system is self-protected by a detachable automatically triggered hydraulic stop.

Advantages

- Simulation of very heavy weights (up to 200 tons)

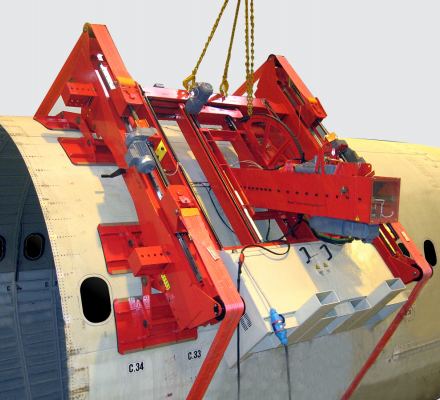

- The machine occupies very little floor space and has no civil-works component

- Low adjustment, assembly and disassembly times

- Machine protected by a detachable hydraulic stop; absence of suspended load thanks to its horizontal position