Mechanical test benches

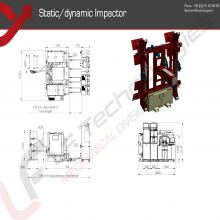

Combined static/dynamic impactor

Technical description

Main functions

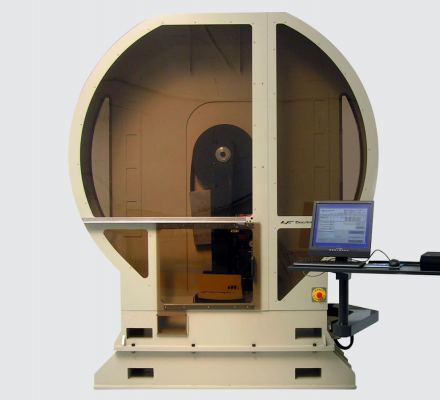

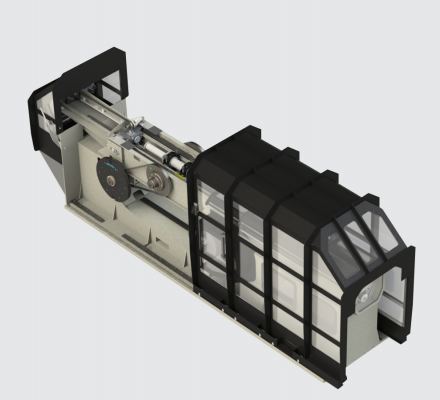

The combined static/dynamic impactor allows to carry out impact tests in all orientations (horizontal or vertical). The shocks are generated by a linear impactor, driven by an electric servomotor. The position and speed measurement with respect to the impacted object makes it possible to measure the potential energy of the shock and the energy absorbed by the sample.

The position and orientation of the impact are adjustable and motorized.

This bench also enables to conduct static compression tests up to 80 kN.

Operating mode

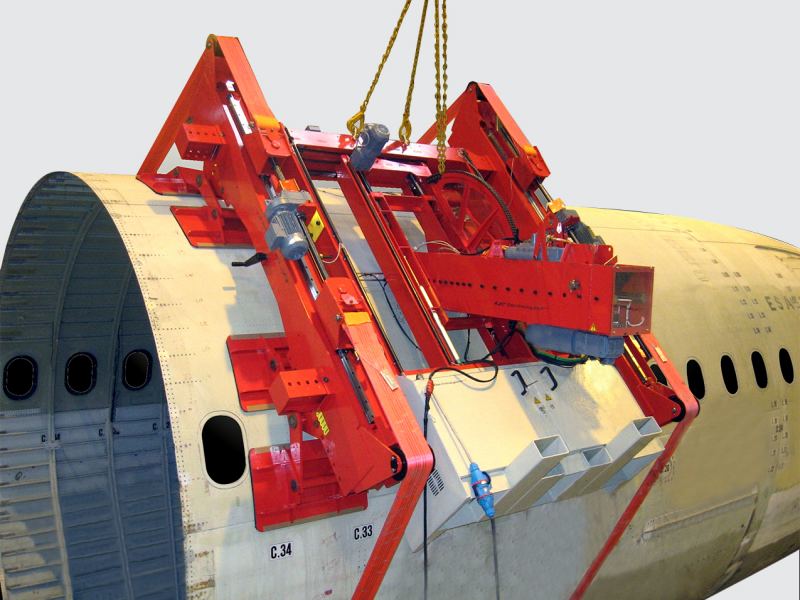

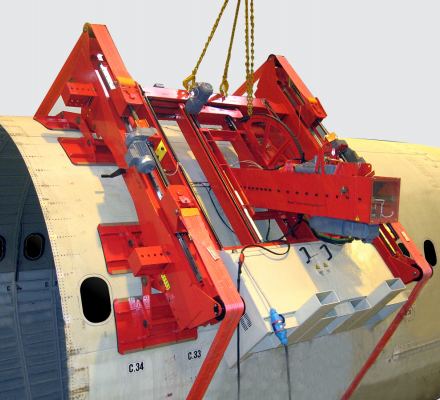

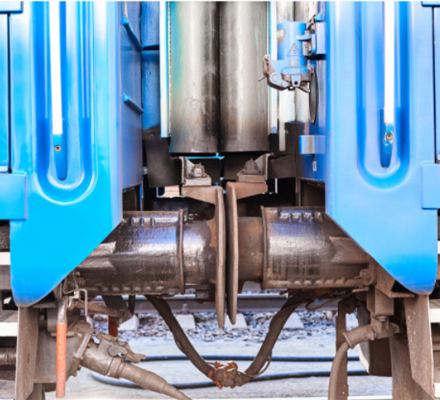

The machine is attached to a test support or directly to the tested element. This hooking is achieved by an automatic servo-controlled system of tightening straps which allows to avoid the use of a gantry of large dimensions (test on an aircraft for example).

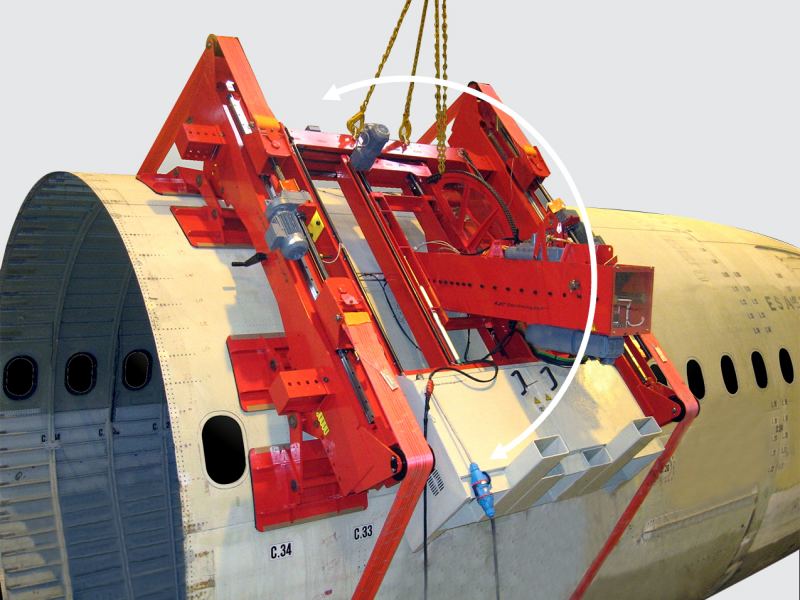

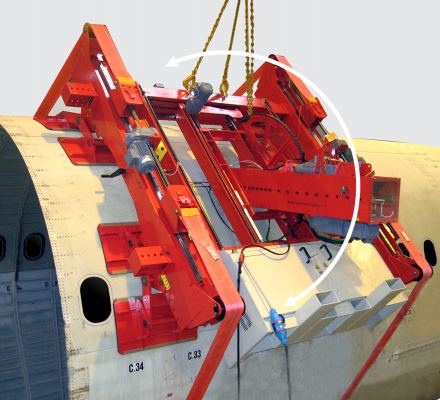

The user regulates the position and orientation of the impactor. The test bench automatically searches for a contact position. The impactor is then powered onto the product/sample at a regulated speed. The impactor is automatically caught up to avoid shocks after rebound.

The differential position of the impactor/target is measured by a laser measuring.

Advantages

- Autonomous hooking on the tested product thanks to automatic tightening straps

- Shots possible in all directions with motorized settings

- Accurate firing position thanks to automatic X/Z adjustment with laser aiming

- Adjustable position of the backing pads to adapt to the product diameter