Customer

Our client is a precision engineering specialist in the manufacturing of custom hubs for high performance bicycle wheels.

Tested product

Bicycle wheels

Objective

Testing the life of bicycle wheels

Problematic issues

The endurance test bench must be modular, i.e. each module must perform a particular simulation function.

Solution and result

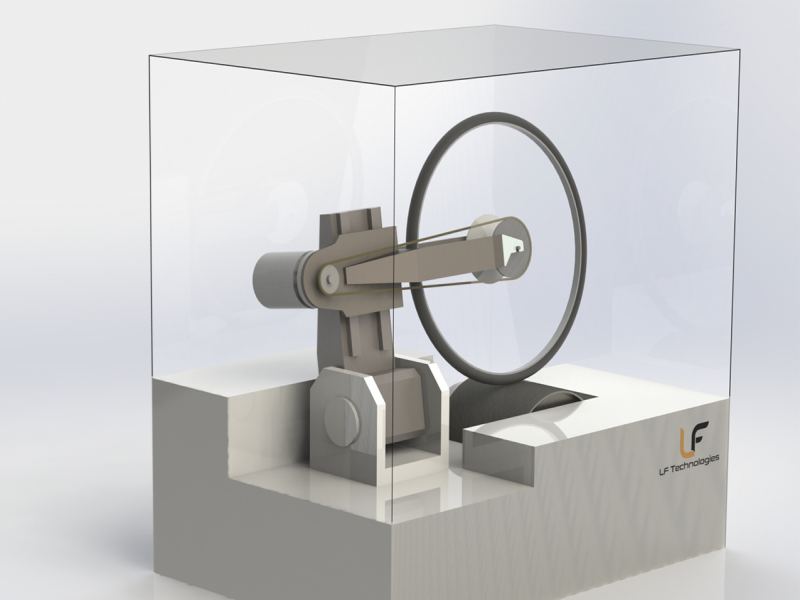

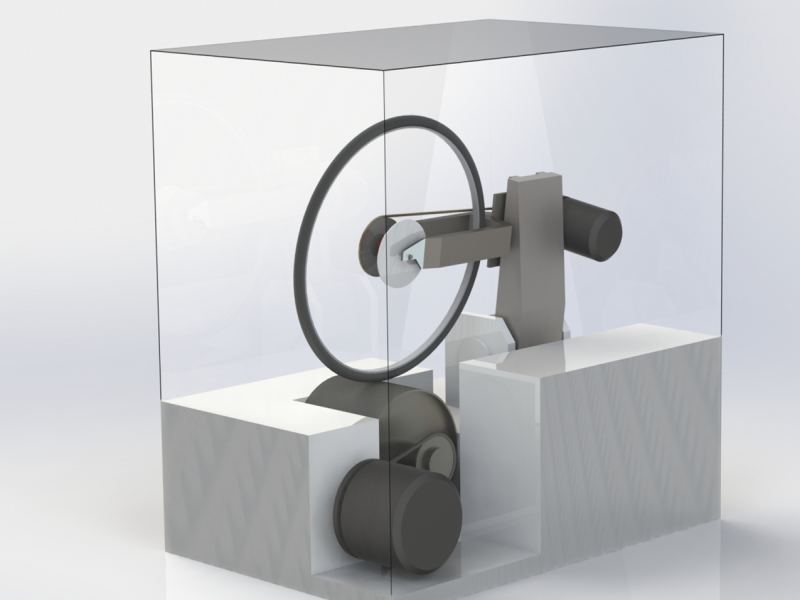

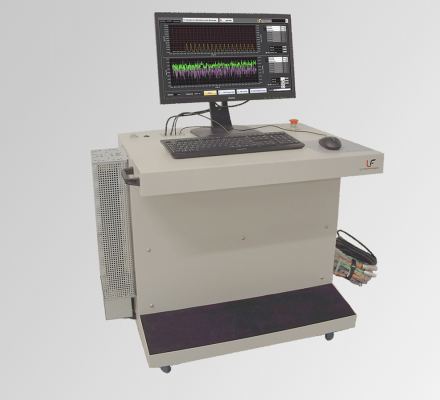

The endurance test bench designed by our teams is self-supporting and ergonomic. The wheel to be tested is fixed on an arm, which is itself fixed to a mobile trolley with a vertical axis allowing the weight of the cyclist on the wheel to be simulated.

The system is designed to test different wheel sizes with a minimum of handling. The operator can adjust the inclination of the wheel by means of a bracket, +/- 30° from the vertical.

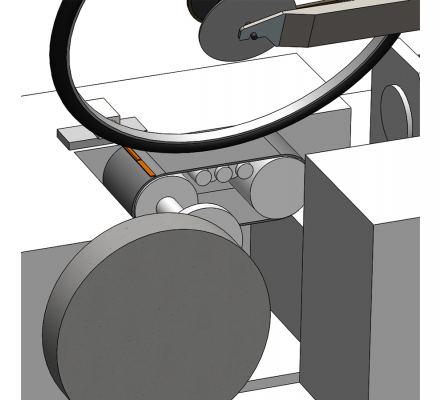

The bicycle wheel rolls on a motorised drum to simulate the movement of the road relative to the wheel. The cyclist's weight is simulated by both the vertical support force and the inertia of the drum.

Wheel accelerations are measured via an accelerometer and the downforce (simulating the rider's weight) is measured by a load cell. This drum can also be replaced by a treadmill.

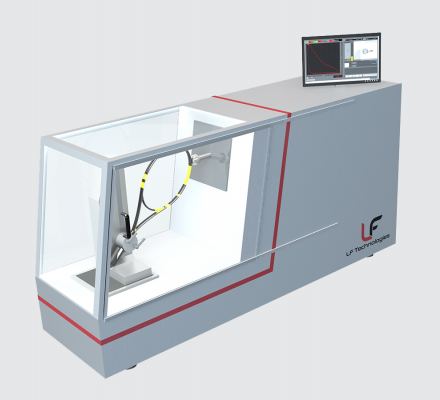

A special software program is used to create test programs that combine all the desired functions. Data such as speed and distance covered by the wheel are saved in an automatic test report.

The bicycle wheel endurance test stand is set up in the test laboratory to test the fatigue strength and service life of bicycle wheels before they are put into production.

As the test bench is modular, we can consider adding additional functions such as bump simulation, braking simulation, etc.